Visible-light response supported-type Ru catalyst

A supported catalyst, catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, organic chemistry, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

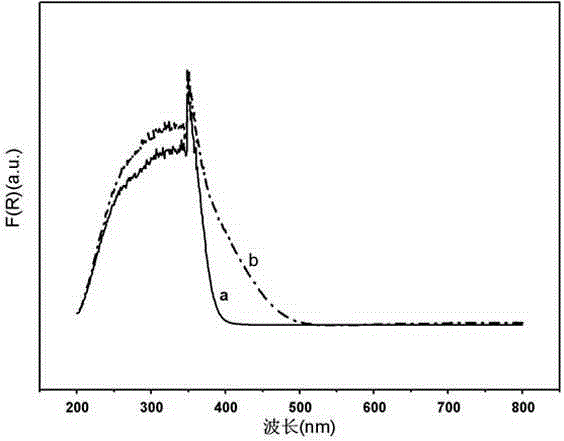

[0023] TiO (2-x) N x Catalyst preparation

[0024] TiO (2-x) N x Carrier: Dissolve 15 mL of tetra-n-butyl titanate in 50 mL of absolute ethanol and stir vigorously at a constant speed to obtain a light yellow transparent solution A. Then, weigh 8 g of urea and dissolve it in 100 mL of distilled water, and add 1 mol / L of HNO 3 The pH of the solution was adjusted to 3 to obtain B solution. Add solution A dropwise to solution B under vigorous stirring, and continue to react for 3 hours after the dropwise addition to completely hydrolyze tetra-n-butyl titanate to obtain a white milky solution. Finally, the hydrolyzate was dried in an oven at 80°C, calcined in a muffle furnace at 400°C for 3 hours, ground and sieved to obtain a yellow nitrogen-doped titania carrier with a nitrogen-doped content of 2.57wt% (measured by EA).

[0025] Next, the active component Ru was loaded: 0.5 g of nitrogen-doped titanium dioxide was dried in a vacuum oven at 60° C. for 2 h. Then, to the dri...

Embodiment 2

[0027] Catalyst Performance Evaluation

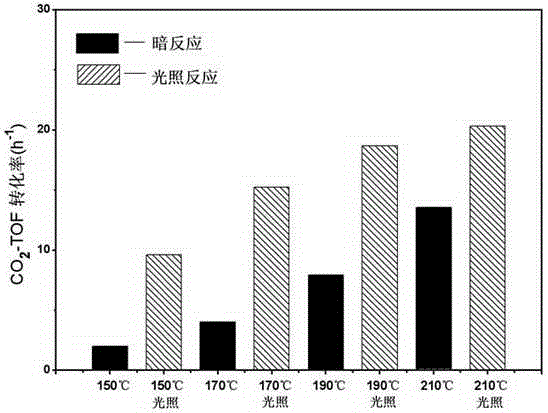

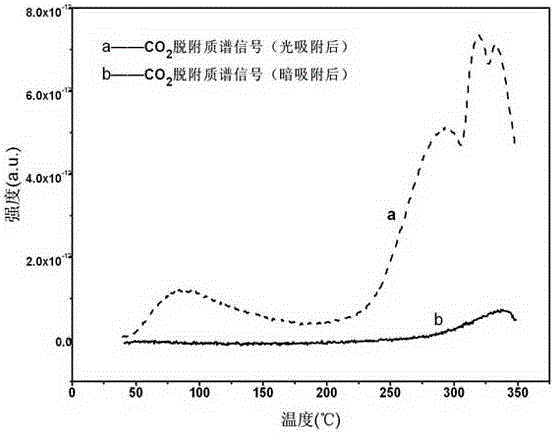

[0028] The prepared catalyst of embodiment 1 catalyzes CO 2 The performance evaluation of the methanation reaction was carried out on a normal pressure continuous flow reactor with a flat heater. About 0.23g of catalyst (particle size about 0.2~0.3mm (60~80 mesh)) is packed in a quartz flat plate reactor (length 30mm*width 15mm*height 1mm), and the rest of the space is filled with quartz sand of the same particle size. Use 12Vol%H before the reaction 2 Reduction at 220°C for 3 hours, after cooling down, switch to reaction gas for comparative test of low-temperature thermocatalytic dark reaction and light reaction, in which CO 2 and H 2 The contents of He are fixed at 0.6Vol% and 2.4Vol%, respectively, He gas is used as the balance supplementary gas, and the total flow rate of the reaction gas is about 60mL / min. The reaction temperature is regulated by a temperature program temperature controller, and the visible light source is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com