Method for improving acetylglucosamine yield of recombinant bacillus subtilis by knocking out argCJBD

A Bacillus subtilis, acetamido technology, applied in the field of genetic engineering, can solve problems such as the weakening of metabolic flow competition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

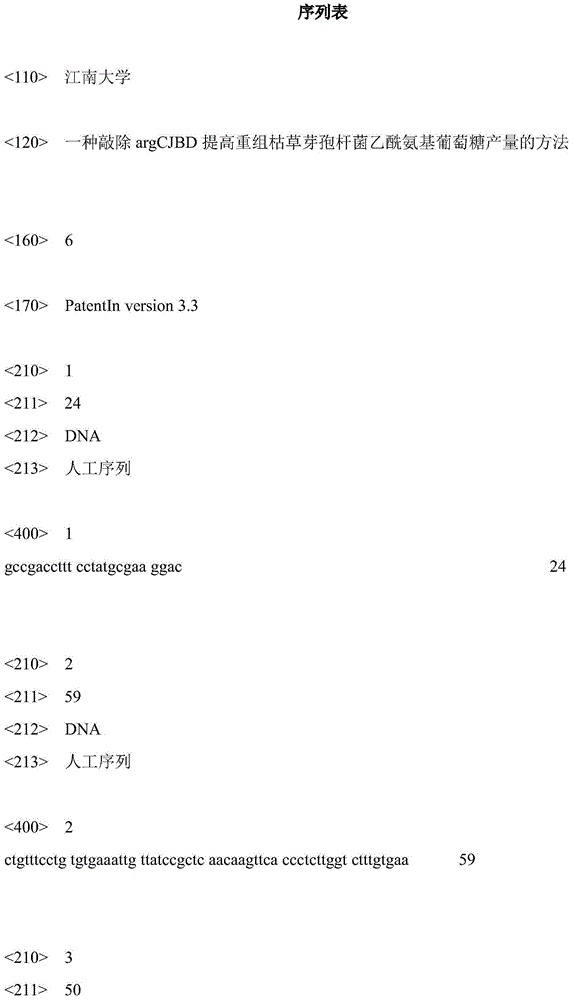

[0019] Example 1 Knockout of the gene encoding acetylglutamate semialdehyde dehydrogenase (argC), the gene encoding ornithine acetyltransferase (argJ), the gene encoding acetylglutamate kinase (argB) and the gene encoding acetylornithine transaminase (argD)

[0020] According to the upstream and downstream sequences of the gene argC encoding acetylglutamate semialdehyde dehydrogenase and the gene argD encoding acetylornithine transaminase of Bacillus subtilis (Bacillus subtilis168, purchased from the American Type Microorganism Collection, ATCC No. 27370) published on NCBI, the knockout gene was designed. Out-of-frame homologous arm amplification primers, the upstream and downstream primers of the left arm are: arg1-L-F: 5'-GCCGACCTTTCCTATGCGAAGGAC-3' and arg1-L-R: 5'-CTGTTTCCTGTGTGAAATTGTTATCCGCTCAACAAGTTCACCCTCTTGGTCTTTGTGAA-3'; the upstream and downstream primers of the right arm are: arg1 -R-F:5'-GTCGTGACTGGGAAAACCCTGGCGCTCATCATTCCGCTGTAAACCAGTGA-3' and arg1-R-R:5'-CGCGAGC...

Embodiment 2

[0021] The construction of embodiment 2 recombinant Bacillus subtilis

[0022] Transform the constructed knockout frame into Bacillus subtilis BSGN6-P xylA -glmS -P 43 -GNA1, through bleomycin resistance plate screening and colony PCR verification, it was confirmed that argCJBD was knocked out successfully, and recombinant Bacillus subtilis BSGN6ΔargCJBD::lox72-P was obtained xylA -glmS -P 43 -GNA1. Bacillus subtilis BSGN6-P xylA -glmS -P 43 - For the construction method of GNA1, please refer to the literature Liu, Y.etal.Modular pathway engineering of Bacillus subtilis for improved N-acetylglucosamineproduction.Metab.Eng.23:42-52,2014.

Embodiment 3

[0023] Example 3 Fermentative production of acetylglucosamine

[0024] The seeds cultivated at 37° C. and 200 rpm for 12 hours were transferred to the fermentation medium at an inoculum size of 5%, and cultivated at 37° C. and 200 rpm for 30 hours. After 30 hours of fermentation, the content of acetylglucosamine in the fermentation supernatant reached 6.4g / L. By knocking out argCJBD, the host bacteria are blocked from glutamic acid to arginine, which promotes the reaction of glutamic acid into glutamine, accumulates amino donors required for the synthesis of acetylglucosamine, and realizes the synthesis of acetylglucosamine. The extracellular production of recombinant Bacillus subtilis increased by 16.3% compared with that before knockout.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com