PBO fiber resin diamond wire and preparation method thereof

A technology of fiber resin and diamond wire, which is applied in the field of PBO fiber resin diamond wire and its preparation, can solve the problems of high cost, low material utilization rate, large slit of resin diamond wire, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

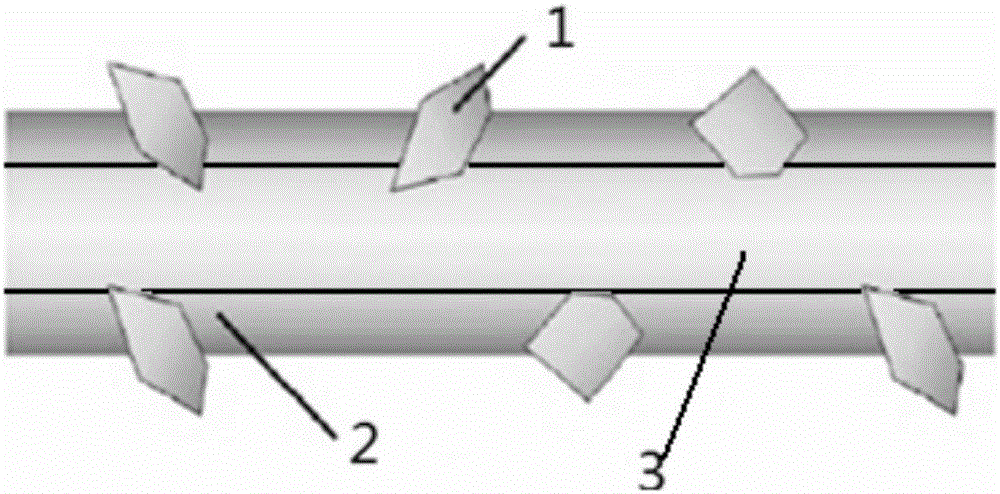

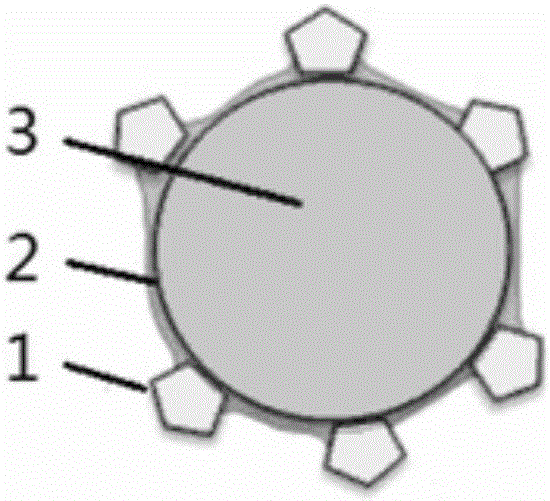

[0035] The invention provides a kind of preparation method of PBO fiber resin diamond wire, comprising the following steps:

[0036] A) performing plasma treatment on the PBO fiber busbar to obtain a plasma-treated busbar, the diameter of the PBO fiber busbar being 65-80 μm;

[0037] B) Coating the resin slurry on the plasma-treated bus bar and curing it to obtain the PBO fiber resin diamond wire.

[0038] In the present invention, the surface of the PBO fiber busbar is preferably cleaned, dried and then plasma-treated to obtain a plasma-treated busbar. The present invention preferably uses a mixed solution of pure water and alcohol to clean the busbar, and the ratio of the alcohol is preferably 10-20%, more preferably 13-15%; the present invention has no special restrictions on the type of the cleaning device , in the present invention, the cleaning device is 1-3 meters long, the busbar enters the cleaning device from the inlet, and blows the surface after coming out from th...

Embodiment 1

[0047] Use lotion to clean the PBO fiber busbar. The lotion is pure water, add 10% alcohol, and dry it at 40°C after cleaning. The busbar after drying enters the surface plasma treatment stage. Placed symmetrically, with a diameter of 10mm, the two faces of the busbar are treated separately. The line speed corresponding to the busbar is 10m / min, and the plasma power is 0.5kw.

[0048] The resin slurry was coated on the surface of the plasma-treated busbar, pre-cured at 150°C for 3s, and then cured at 200°C for 8 hours to obtain a PBO fiber resin diamond wire. The resin slurry contains 20% phenolic resin, 20% silicon carbide, 40% diamond particles with a particle size of 8 μm and 20% acetone. The thickness of the coating on the surface of the finally obtained PBO fiber resin diamond wire is 6 μm, and the composition content is 25% of phenolic resin, 25% of silicon carbide and 50% of diamond.

[0049] The present invention uses the PBO fiber resin diamond wire obtained in this...

Embodiment 2

[0051] Use lotion to clean the PBO fiber busbar. The lotion is pure water, add 10% alcohol, and dry it at 50°C after cleaning. The busbar after drying enters the surface plasma treatment stage. Placed symmetrically, with a diameter of 40mm, the two faces of the busbar are treated separately. The line speed corresponding to the busbar is 80m / min, and the plasma power is 5kw.

[0052] The resin slurry was coated on the surface of the plasma-treated busbar, pre-cured at 250°C for 3s, and then cured at 200°C for 8 hours to obtain a PBO fiber resin diamond wire. The resin slurry contains 20% phenolic resin, 25% alumina with a particle size of 1 μm, 40% diamond particles with a particle size of 8 μm and 15% acetone. The thickness of the coating on the surface of the finally obtained PBO fiber resin diamond wire is 7 μm, and the composition content is 25% of phenolic resin, 30% of aluminum oxide and 45% of diamond.

[0053] The present invention uses the PBO fiber resin diamond wir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com