An anode and a battery stack unit of a high-temperature solid-state fuel cell

A fuel cell stack and fuel cell technology, applied in the direction of solid electrolyte fuel cells, fuel cells, fuel cell grouping, etc., can solve the problems of nickel particles reducing anode porosity and electrical conductivity and current collection performance, battery performance attenuation, battery structure damage, etc. , to achieve the effect of solving the problem of performance attenuation, improving stability and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

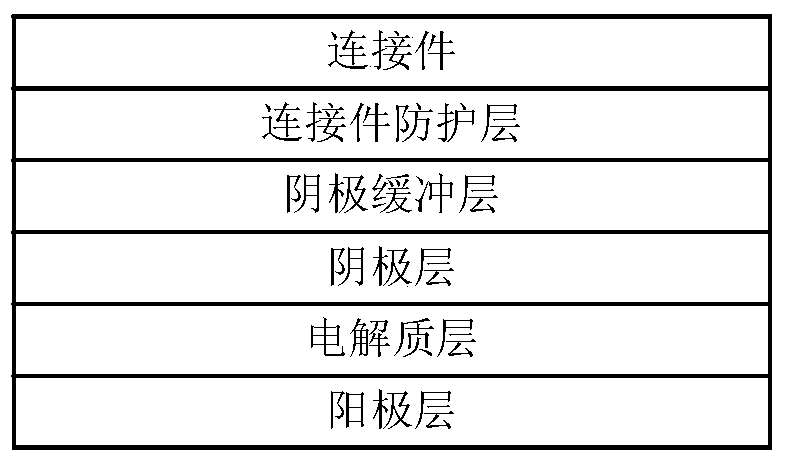

[0037] In this embodiment, the high temperature solid fuel cell stack unit such as figure 1 As shown, it is composed of a single cell and a metal connector. The single cell is composed of an anode layer, an electrolyte layer, a cathode layer and a cathode buffer layer. The connector protective layer is between the single cell and the metal connector.

[0038] Anode layer materials are NiO (nickel oxide), YSZ (yttria stabilized zirconia) and Ti 3 AlC 2 , prepared by the following method: the above three materials are mixed in proportion, Ti 3 AlC 2 Accounting for 15% of the mass of the substance to be substituted (nickel or / and nickel compound), after grinding and dispersing, it is dried and heat-treated to obtain the anode powder; the anode powder is prepared into a slurry, and when the battery is an anode-supported type, the slurry The slurry is cast as the anode, and when the battery is electrolyte-supported, the slurry is screen-printed as the anode.

[0039] The electr...

Embodiment 2

[0048] In this embodiment, the structure of the high-temperature solid-state fuel cell stack unit is exactly the same as that of the high-temperature solid-state fuel cell stack unit in Embodiment 1.

[0049] The difference is that the ceramic high-temperature conductive material contained in the anode layer, cathode layer, cathode buffer layer and connector protective layer is changed to Ti 3 C 2 , the substitution ratio is the same as in Example 1.

[0050] Because Ti 3 C 2 with Ti 3 AlC 2 The high-temperature electrical conductivity is similar, and the electrical performance of the above-mentioned high-temperature solid-state fuel cell stack is basically the same as that of Example 1, except that:

[0051] with Ti 3 AlC 2 Compared to Ti 3 C 2 The material has strong plasticity, and its replacement in the battery anode layer, cathode layer and cathode buffer layer can better improve the contact effect between the battery and the connector.

Embodiment 3

[0053] In this embodiment, the structure of the high-temperature solid-state fuel cell stack unit is exactly the same as that of the high-temperature solid-state fuel cell stack unit in Embodiment 1.

[0054] The difference is that the ceramic high-temperature conductive material contained in the anode layer, cathode layer, cathode buffer layer and connector protective layer is changed to ZrB 2 , the substitution ratio is the same as in Example 1.

[0055] ZrB 2 The high-temperature electrical conductivity of the material is higher than that of Ti 3 C 2 with Ti 3 AlC 2 High, the electric performance of above-mentioned warm solid-state fuel cell stack is better than embodiment 1 and embodiment 2, and difference is:

[0056] ZrB 2 Although the thermal expansion coefficient of stainless steel is in the same order of magnitude as that of stainless steel, there is a large difference. When used as a protective layer for connectors, a transition layer needs to be sprayed in adv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com