Method for improving charge-discharge cycling capacity of molybdenum disulfide by doping graphene and titanium dioxide

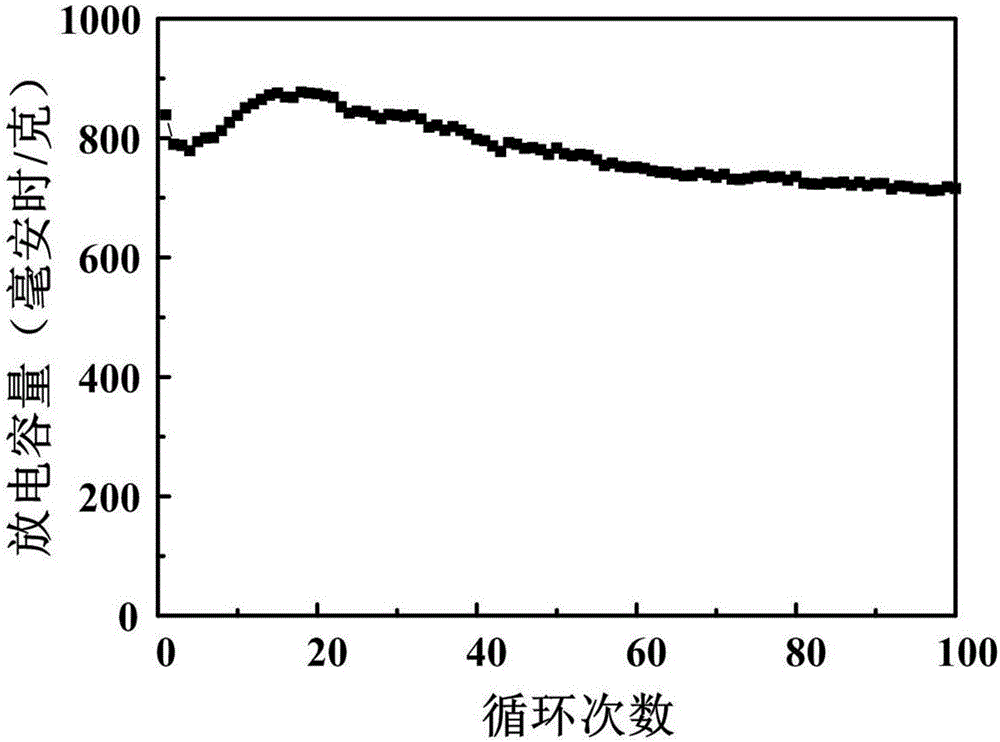

A technology of titanium dioxide and molybdenum disulfide, which is applied in the direction of circuits, electrical components, battery electrodes, etc., can solve the problems that the discharge specific capacity needs to be further improved and needs to be further improved, and achieve improved cycle performance, volume change suppression, and contact area. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

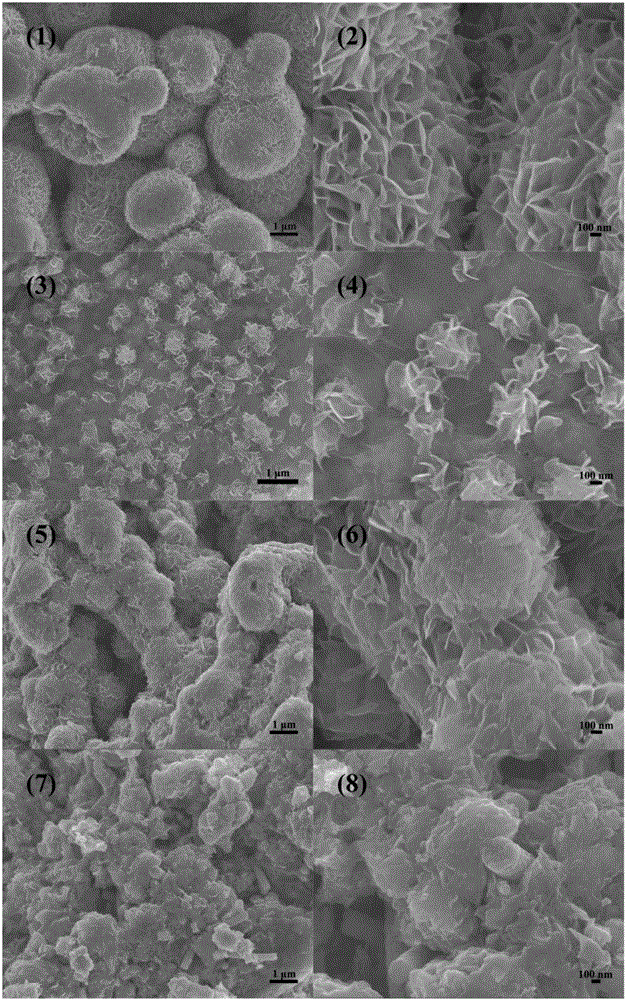

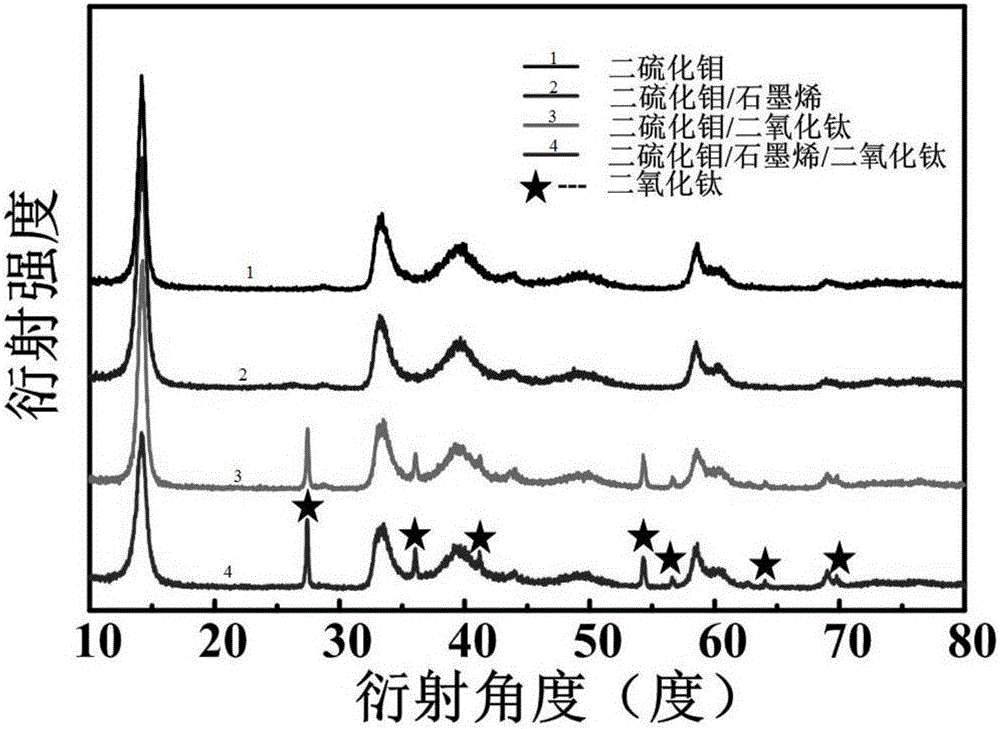

[0023] (1) Preparation of fibrous titanium dioxide by electrospinning: 3 ml of titanium tetraisopropoxide, 2 ml of acetic acid, 0.3 g of polyvinylpyrrolidone and absolute ethanol were mixed, and the oscillator oscillated for 1440 minutes; 1. Spinning under the condition of 1 milliliter of advancing speed per hour and 10 centimeters of receiving distance; standing for 1440 minutes, then roasting for 360 minutes at 510 degrees centigrade in an air atmosphere to obtain fibrous titanium dioxide;

[0024] The polyvinylpyrrolidone can be replaced by polyethylene glycol, cetyltrimethylammonium bromide or sodium dodecylbenzenesulfonate.

[0025] (2) Dissolve 0.024 g of graphite oxide in 30 ml of deionized water, ultrasonicate for 30 minutes, add titanium dioxide and sodium molybdate or ammonium molybdate, stir for 5 minutes, then add thiourea, and stir for 5 minutes.

[0026] (3) Transfer the above solution to a reaction kettle for hydrothermal reaction at 200 degrees Celsius for 1440...

Embodiment 2

[0030] (1) Preparation of fibrous titanium dioxide by electrospinning: 0.5 ml of titanium tetraisopropoxide, 0.4 ml of acetic acid, 0.05 g of polyvinylpyrrolidone and absolute ethanol were mixed, and the oscillator oscillated for 720 minutes; , 0.1 milliliters of per hour advancing speed and spinning under the condition of 4 centimeters of receiving distances; Stand still for 720 minutes, then roast under 400 degrees centigrade air atmosphere for 120 minutes, obtain fibrous titanium dioxide;

[0031] The polyvinylpyrrolidone can be replaced by polyethylene glycol, cetyltrimethylammonium bromide or sodium dodecylbenzenesulfonate.

[0032] (2) Dissolve 0.01 g of graphite oxide in 10 ml of deionized water, ultrasonicate for 15 minutes, add titanium dioxide and sodium molybdate or ammonium molybdate, stir for 2 minutes, then add thiourea, and stir for 2 minutes.

[0033] (3) Transfer the above solution to a reaction kettle for hydrothermal reaction at 150 degrees Celsius for 720 m...

Embodiment 3

[0036] (1) Preparation of fibrous titanium dioxide by electrospinning: 1 ml of titanium tetraisopropoxide, 0.8 ml of acetic acid, 0.1 g of polyvinylpyrrolidone and absolute ethanol were mixed, and the oscillator oscillated for 960 minutes; , 0.4 milliliters of per hour advancing speed and spinning under the condition of 6 centimeters of receiving distances; Stand still for 960 minutes, then roast 180 minutes under 450 degrees centigrade air atmosphere, obtain fibrous titanium dioxide;

[0037] The polyvinylpyrrolidone can be replaced by polyethylene glycol, cetyltrimethylammonium bromide or sodium dodecylbenzenesulfonate.

[0038] (2) Dissolve 0.015 g of graphite oxide in 15 ml of deionized water, ultrasonicate for 20 minutes, add titanium dioxide and molybdenum or sodium ammonium molybdate or ammonium molybdate, stir for 3 minutes, then add thiourea, and stir for 3 minutes.

[0039] (3) Transfer the above solution to a reaction kettle for hydrothermal reaction at 160 degrees ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com