Method for synchronously extracting iron and niobium from Bayan Obo low-grade ores

A synchronous extraction and low-grade technology, applied in the direction of fluidized bed furnace, etc., can solve the problems of limited application and limited dissolution, and achieve the effects of low processing cost, reduced energy consumption, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

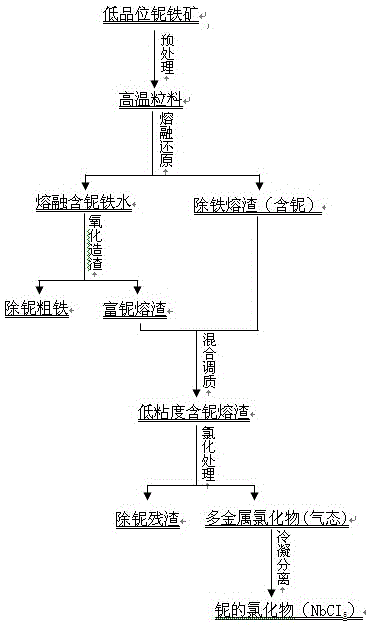

Image

Examples

Embodiment 1

[0040] Extraction and separation of iron and niobium in niobium iron ore

[0041] The content (%) of metal oxide in the raw material is: T Fe 15~24;Nb 2 o 5 0.15~0.20; REO6~10.

[0042] It is divided into three parts: smelting reduction of mineral powder, extraction of niobium by melting slag, and condensation and separation of flue gas.

[0043] Smelting reduction:

[0044] 1) The iron ore powder and hot flue gas are combined into the cyclone preheating reducer through the pipeline for preheating and then sent to the melter gasifier.

[0045] 2) Fuel charge and injected O in the melter gasifier 2 React with pulverized coal to generate gas, molten iron, and liquid slag, which are discharged through their respective outlets.

[0046] 3) The coal gas generated after the reaction in the melter-gasifier and the water vapor or CO injected into the upper end of the melter-gasifier 2 After exchanging heat with pulverized coal, it enters the cyclone preheating reducer for prehe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com