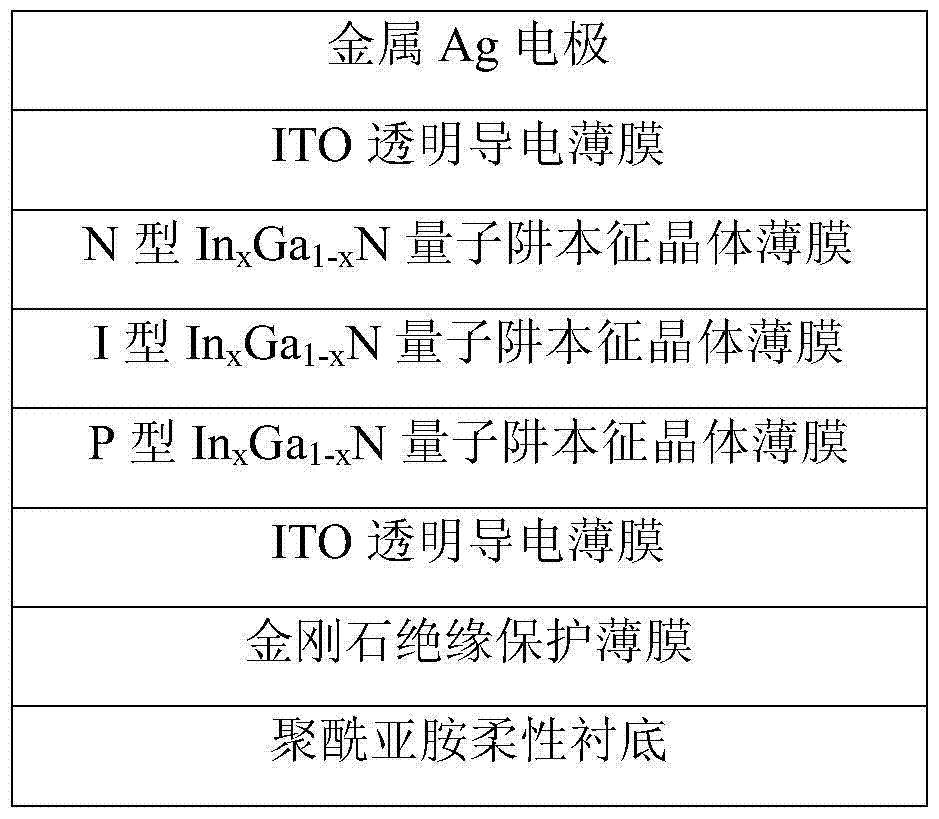

Flexible substrate thin film solar cell with diamond protective layer structure and preparation method

A technology for solar cells and flexible substrates, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of poor market competitiveness of thin-film solar cells, poor photoinduced performance stability of solar cells, and low photoelectric conversion efficiency, etc., to improve Photoelectric conversion efficiency, increased market competitiveness, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

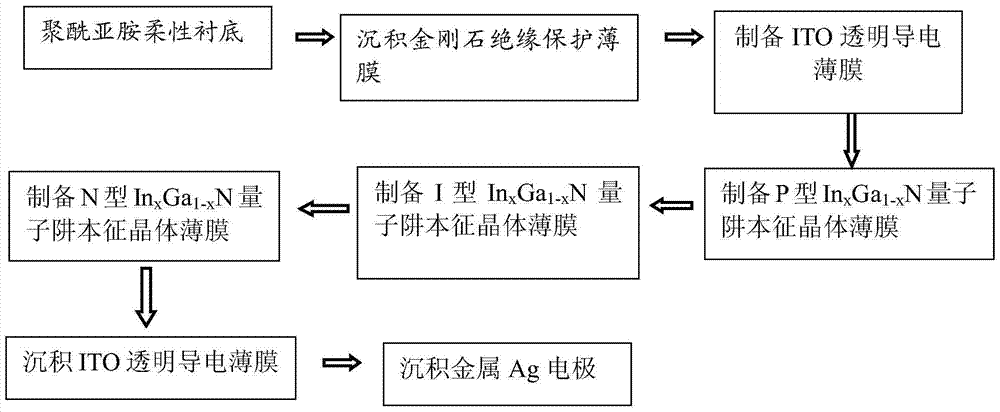

[0026] see figure 1 combine figure 2 .

[0027] (1), the flexible substrate polyimide (PI) substrate substrate is first cleaned with ionized water for 5 minutes, then dried with nitrogen and sent to the magnetron sputtering reaction chamber, at 8.0 × 10 -4 Under the condition of Pa vacuum, the diamond anti-corrosion insulating layer is prepared by deposition. The process parameter conditions are: hydrogen and methane are used as the mixed gas reaction source, the flow ratio of hydrogen and methane is 10:1, the substrate temperature is 100°C, and the deposition time is 30 minutes.

[0028] (2), using magnetron sputtering to prepare ITO-based transparent conductive film; its process parameter conditions are: oxygen gas is used as the gas reaction source, the oxygen flow rate is 20 sccm, the purity of the reactive sputtering indium metal target is 99.99%, the substrate The temperature was 150°C and the deposition time was 10 minutes.

[0029] (3) Continue to prepare the PIN ...

Embodiment 2

[0033] (1), the flexible substrate polyimide (PI) substrate substrate is first cleaned with ionized water for 5 minutes, then dried with nitrogen and sent to the magnetron sputtering reaction chamber, at 8.0 × 10 -4 Under the condition of Pa vacuum, the diamond anti-corrosion insulating layer is prepared by deposition. The process parameter conditions are: hydrogen and methane are used as the mixed gas reaction source, the flow ratio of hydrogen and methane is 10:1, the substrate temperature is 200°C, and the deposition time is 40 minutes.

[0034] (2), using magnetron sputtering to prepare ITO-based transparent conductive film; its process parameter conditions are: oxygen gas is used as the gas reaction source, the oxygen flow rate is 15 sccm, the purity of the reactive sputtering indium metal target is 99.99%, the substrate The temperature was 80°C and the deposition time was 5 minutes.

[0035] (3) Continue to prepare the PIN layer In with adjustable bandgap in the electro...

Embodiment 3

[0039] (1), the flexible substrate polyimide (PI) substrate substrate is first cleaned with ionized water for 5 minutes, then dried with nitrogen and sent to the magnetron sputtering reaction chamber, at 8.0 × 10 -4 Under the condition of Pa vacuum, the diamond anti-corrosion insulating layer is prepared by deposition. The process parameter conditions are: hydrogen and methane are used as the mixed gas reaction source, the flow ratio of hydrogen and methane is 10:1, the substrate temperature is 300°C, and the deposition time is 45 minutes.

[0040] (2), using magnetron sputtering to prepare ITO-based transparent conductive film; its process parameter conditions are: oxygen gas is used as the gas reaction source, the oxygen flow rate is 20 sccm, the purity of the reactive sputtering indium metal target is 99.99%, the substrate The temperature was 150°C and the deposition time was 9 minutes.

[0041] (3) Continue to prepare the PIN layer In with adjustable bandgap in the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com