Preparation method of modified polypropylene nano fiber and oil absorption felt made from modified polypropylene nano fiber

A technology of nanofibers and polypropylene, applied in the direction of single-component polypropylene artificial filaments, fiber chemical characteristics, chemical instruments and methods, etc., can solve the problems of high device requirements, high cost, and high conductivity requirements of solutions, and achieve Good application prospect, strong oil absorption rate, easy to manufacture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

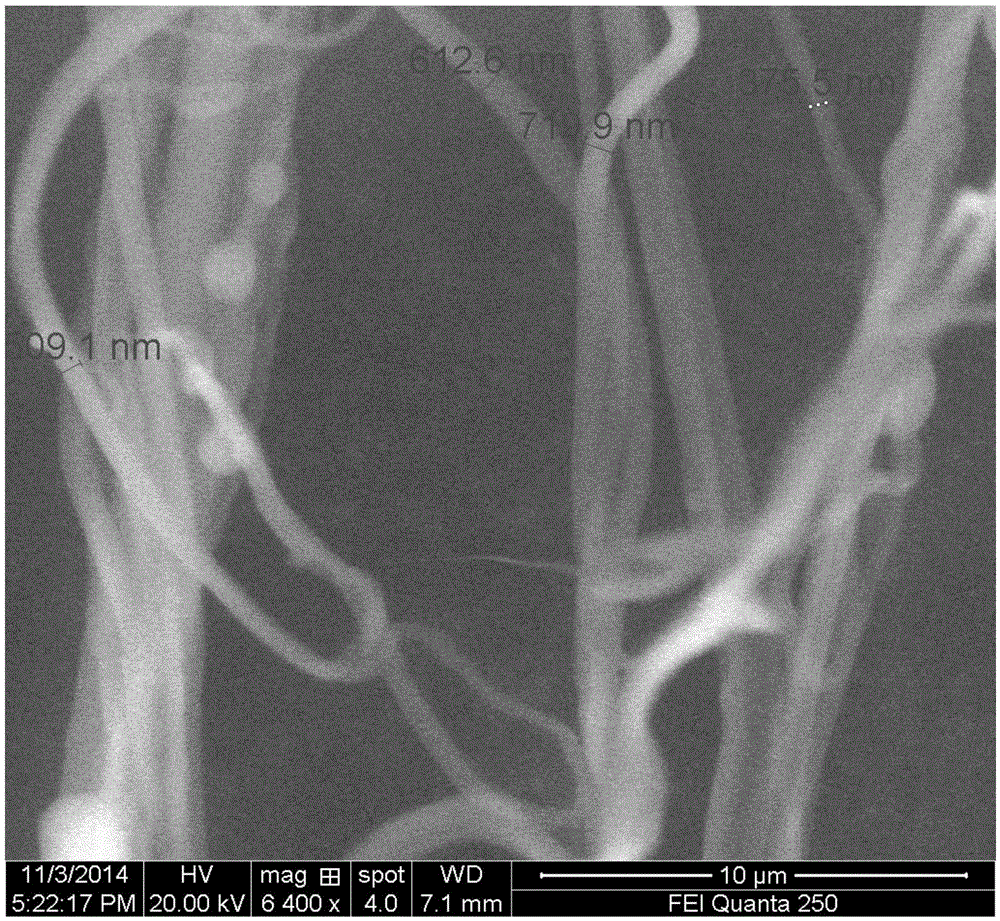

[0048](1) high-speed premixing of island phase polymer polypropylene, marine phase polymer polylactic acid and inorganic nanomaterial nano calcium carbonate, wherein the mass fraction of polypropylene is 5%, and the inorganic nano material nano calcium carbonate mass fraction is 0.01%, The balance is marine phase polymer polylactic acid;

[0049] (2) The mixture is melt-extruded and directly cooled and granulated in the air;

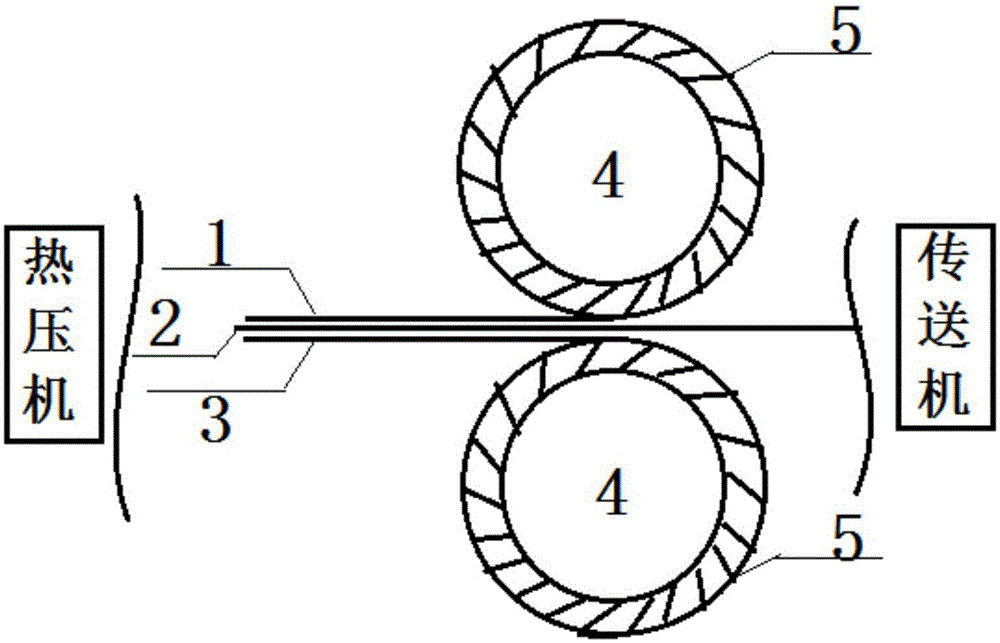

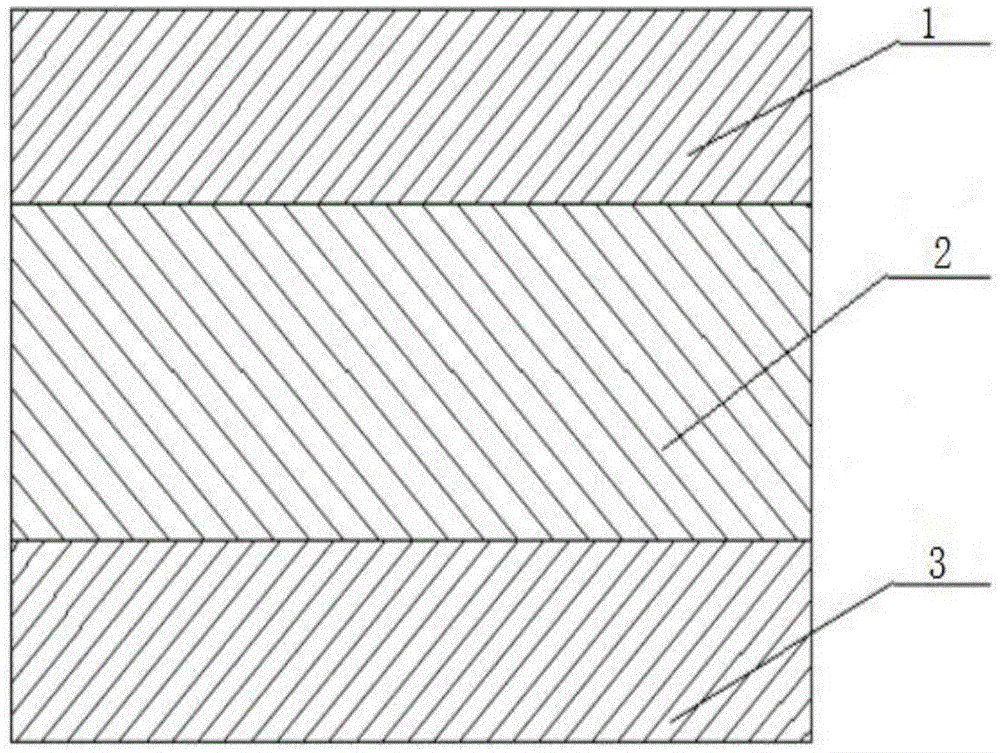

[0050] (3) the masterbatch in step (2) is produced with melt-blown equipment to obtain superfine composite fibers;

[0051] (4) Dissolving and removing the marine phase polymer in the ultrafine composite fiber with a solvent, and obtaining the modified polypropylene nanofiber after drying.

Embodiment 2

[0053] (1) high-speed premixing of island phase polymer polypropylene, marine phase polymer polylactic acid and inorganic nanomaterial nano calcium carbonate, wherein the mass fraction of polypropylene is 5%, and the inorganic nano material nano calcium carbonate mass fraction is 0.01%, The balance is marine phase polymer polylactic acid;

[0054] (2) The mixture is melt-extruded and directly cooled and granulated in the air;

[0055] (3) the masterbatch in step (2) is produced with melt-blown equipment to obtain superfine composite fibers;

[0056] (4) Dissolving and removing the marine phase polymer in the ultrafine composite fiber with a solvent, and obtaining the modified polypropylene nanofiber after drying.

Embodiment 3

[0058] (1) high-speed premixing of island phase polymer polypropylene, marine phase polymer polylactic acid and inorganic nanomaterial nano-calcium carbonate, wherein the massfraction of polypropylene is 15%, and the inorganic nanomaterial nano-calcium carbonate massfraction is 2%, The balance is marine phase polymer polylactic acid;

[0059] (2) The mixture is melt-extruded and directly cooled and granulated in the air;

[0060] (3) the masterbatch in step (2) is produced with melt-blown equipment to obtain superfine composite fibers;

[0061] (4) Dissolving and removing the marine phase polymer in the ultrafine composite fiber with a solvent, and obtaining the modified polypropylene nanofiber after drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com