Novel process for producing hot rolled threaded steel with on-line surface rustproof function through post-rolling water penetration controlled cooling process

A rebar and new process technology, applied in the field of hot-rolled rebar production line, can solve the problems of severe corrosion of hot-rolled products, achieve high economy and environmental protection, reduce the addition of strengthening alloy elements, and meet the performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

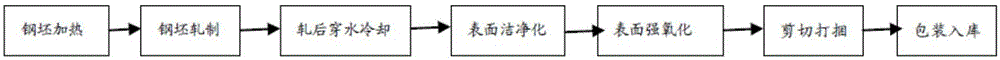

[0029] In order to further clarify the content of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings and embodiments. like figure 1 As shown in the figure, a new process of producing threaded steel on-line surface rust prevention by water-piercing and cooling-controlled process after hot rolling, the specific production process mainly includes billet heating, billet rolling, water-piercing cooling after rolling, surface cleaning, surface strengthening Oxidation, shearing and bundling, packaging and warehousing and other processes are implemented in accordance with the following steps:

[0030] Step 1: Send the billet into the heating furnace for heating;

[0031] Step 2: Roll the rolled piece according to the process requirements of the process rolling schedule;

[0032] Step 3: The steel bar rolled by the finished product frame enters the water-through cooler, the cooling pressure is 1.1-2.0Mpa, and the sur...

Embodiment 2

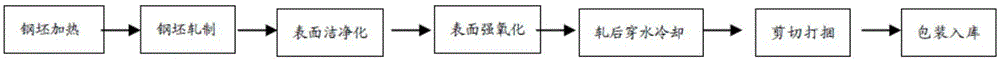

[0039] In order to further clarify the content of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings and embodiments. like figure 2 As shown in Fig. 1, a new process for producing rebar on-line surface rust prevention by water-piercing and cooling-controlled process after hot-rolling, the specific production process mainly includes billet heating, billet rolling, surface cleaning, surface strong oxidation, and water-piercing after rolling. Cooling, shearing and bundling, packaging and warehousing and other processes are implemented in accordance with the following steps:

[0040] Step 1: Send the billet into the heating furnace for heating;

[0041] Step 2: Roll the rolled piece according to the process requirements of the process rolling schedule;

[0042] Step 3: After rolling, the rebar enters the surface purification treatment device, which initially cleans the non-dense scale attached to the surface of...

Embodiment 3

[0048] In order to further clarify the content of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings and embodiments. like image 3 As shown in Fig. 1, a new process for producing rebar on-line surface rust prevention by water-piercing and cooling-controlled process after hot-rolling, the specific production process mainly includes billet heating, billet rolling, surface cleaning, surface strong oxidation, and water-piercing after rolling. Cooling, surface cleaning, surface strong oxidation, shearing and bundling, packaging and warehousing and other processes are implemented in accordance with the following steps:

[0049] Step 1: Send the billet into the heating furnace for heating;

[0050] Step 2: Roll the rolled piece according to the process requirements of the process rolling schedule;

[0051] Step 3: After rolling, the rebar enters the surface purification treatment device, which initially cleans the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com