Polyphenyl ether material for outer sheath of power line in humid environment and preparation method for polyphenyl ether material

A wet environment, polyphenylene ether technology, used in circuits, electrical components, insulated cables, etc., can solve the problem of water resistance and moisture resistance and mildew resistance can not meet the needs of the market, achieve excellent water resistance, improve moisture resistance and mildew resistance. , the effect of reducing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

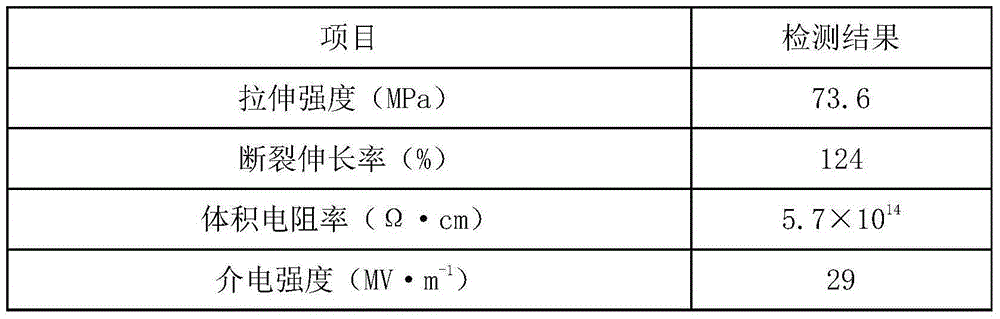

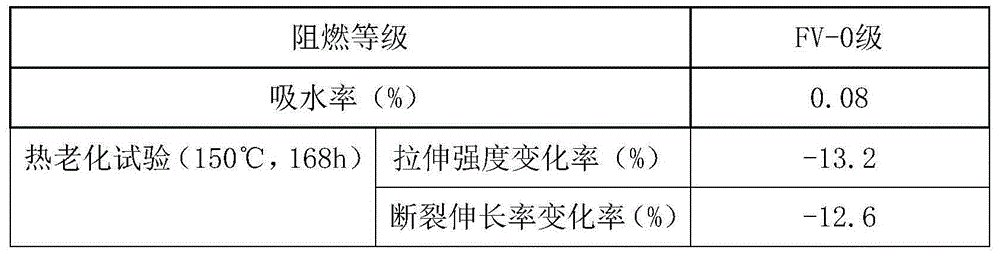

[0014] A polyphenylene ether material for the outer sheath of power cords in humid environments, made of the following raw materials by weight (kg): polyphenylene ether 42, polyparaben 34, polyvinylcarbazole 24, six Chlorocyclotriphosphazene 10, silicone resin microspheres 7, p-chloro-m-xylenol 3, dihydroxy aluminum stearate 4.5, nickel slag powder 18, bromocetylpyridine 12, 2-nitrobiphenyl 3. Jojoba oil 4, ethylene glycol phenyl ether acetate 8, sodium tungstate 6, barium myristate 2.5, barium laurate 1.5, calcined andalusite powder 17, flame retardant particles 13;

[0015] The preparation method of the flame retardant particles is as follows: a, take the raw materials of the following weight (kg): colemanite 25, brucite 18, boehmite 15, expanded graphite 12, basic sodium aluminum carbonate 9, basic Magnesium chloride 7, brominated bisphenol A epoxy resin 26, pentabromobenzyl polyacrylate 28, hexaphenoxycyclotriphosphazene 11, dipentaerythritol diphosphite 7, chlorinated pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com