Soilless culture substrate formula used for vertical greening, and production method therefor

A soilless culture substrate and vertical greening technology, applied in the field of soilless culture substrate formulations, can solve the problems of inability to purify the air, create a better environment, breed bacteria and flying insects, and have large water loss, and achieve good bonding effect, The effect of reducing pollution and overall density reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

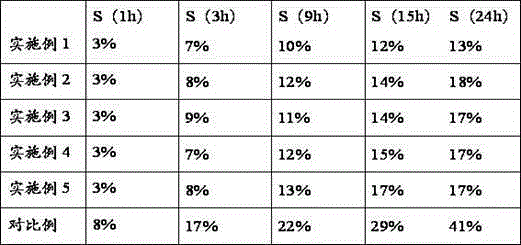

Examples

Embodiment 1

[0057] Put 60020kg of polyethylene glycol; 20016kg of polypropylene glycol; 4kg of vinyl polymer grafted polyether polyol; 0.5kg of dibutyl phthalate into a high-pressure reactor and dehydrate it for 2 hours at 90-100kPa and 100°C. After cooling, add 50kg of natural adhesive mixture and 0.4kg of dibutyltin dilaurate; stir, pass inert gas protection, heat to about 85°C, and react for 3h; finally add 5kg of adsorbent white carbon black, 4kg of calcium oxide, and stir well , cooling down and discharging, and preparing it into an adhesive for later use. Add 1kg of industrial gelatin to 10kg of decomposed branches, leaves, peat, coconut bark, and the mixture in a wet state, stir at a high speed of 35 degrees, and then stand still for 1 minute, then add 3kg of self-made adhesive at a high speed of 40-50 degrees Stir for 2 minutes, then pour into the mold and take out the mold.

Embodiment 2

[0059] Put 60018kg of polyethylene glycol; 20018kg of polypropylene glycol; 18kg of vinyl polymer grafted polyether polyol; 2kg of dibutyl phthalate into the autoclave, dehydrate for 3 hours at 90~100kPa, 100℃, and cool Finally, add 40kg of natural adhesive mixture and 0.4kg of dibutyltin dilaurate; stir, pass inert gas protection, heat to about 85°C, and react for 3h; finally add 3kg of adsorbent white carbon black, 3kg of calcium oxide, and stir well. The temperature is lowered and the material is discharged, and it is prepared into an adhesive for future use. Add 1kg of natural gum to 10kg of decomposed straw, peat, coconut bark, and the mixture in a wet state, stir at a high speed of 35 degrees, and then stand still for 1 minute, then add 3kg of self-made adhesive and stir at a high speed of 40-50 degrees for 2 Minutes, then pour into the mold and take out the mold.

Embodiment 3

[0061] Put polyethylene glycol 600: 24kg; polypropylene glycol 200: 24kg; vinyl polymer grafted polyether polyol: 6kg; Dehydrate for 3 hours, add 30kg of natural binder mixture and 0.45kg of dibutyltin dilaurate after cooling; stir, pass inert gas protection, heat to about 85°C, and react for 3 hours; finally add 2.5kg of adsorbent white carbon black, calcium oxide 4kg, fully stirred, cooled and discharged, prepared as adhesive for later use. Add 1kg of dextrin to 10kg of decomposed straw, peat, branches, leaves, and the mixture in a wet state, stir at a high speed of 35 degrees, and then stand still for 1 minute, then add 3kg of self-made adhesive and stir at a high speed of 40-50 degrees for 2 Minutes, then pour into the mold and take out the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com