Short-circuit-preventing top-emission OLED device and manufacturing method thereof

A top-emission, anti-short-circuit technology, applied in the field of microelectronics, can solve the problems of increasing process complexity, large roughness, tip discharge, etc., and achieve the effect of saving raw material costs, loose selection, and good electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

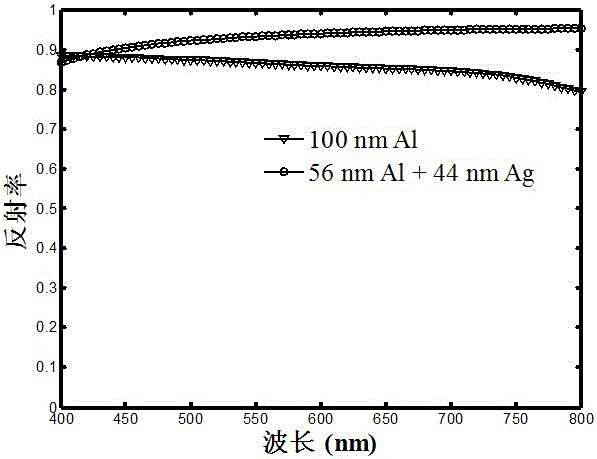

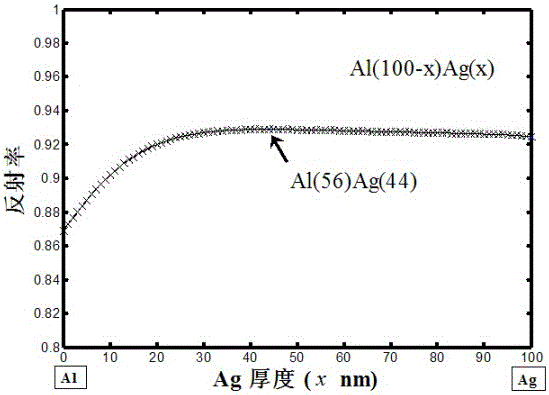

[0057] Example 1: Preparation of a short-circuit-proof top-emitting OLED device.

[0058] The description of the experimental materials and instruments is as follows:

[0059] Use a conventional vacuum thermal evaporator (background vacuum reading below 4×10 -6 Torr) was evaporated, and the whole device was prepared in the same chamber under uninterrupted vacuum conditions; the substrate was placed on the slot of a turntable driven by a gear motor to rotate at a constant speed (about 30RPM) to be inverted (evaporation source The evaporated materials are sequentially deposited on the bottom, the substrate on the top) to form the final device; the organic layer and the metal electrode layer are evaporated by replacing the mask respectively; the film thickness is monitored by a quartz crystal oscillator (SI-TM606A); The ellipsometer (Alpha-SESpectroscopicEllipsometer) calibrates the actual evaporated film thickness.

[0060] The specific operation steps are as follows:

[0061...

Embodiment 2

[0071] Example 2: Preparation of a short-circuit-proof top-emitting OLED device.

[0072] The specific operation steps are as follows:

[0073] (1) Substrate pretreatment: ordinary optical glass (effective area of 0.09cm 2 , that is, 0.3cm×0.3cm) in acetone, absolute ethanol and deionized water for 5 minutes, followed by ultrasonic cleaning for 5 minutes, and drying at 110°C for 30 minutes;

[0074] (2) Evaporation of the aluminum layer in the anode: Cut a high-purity small aluminum block (about 5-6mm in diameter, purchased from alfa, with a purity of 99.999%) into small pieces of about 2-3mm square, and put them into the nitriding In the boron crucible, use tantalum skin to evaporate, adjust the current heating power, and control the evaporation rate to 0.3~0.5nm / s until the aluminum layer evaporated on the glass substrate reaches 60nm;

[0075] (3) Evaporation of the silver layer in the anode: use high-purity silver particles (about 1mm in diameter, purchased from alfa, ...

Embodiment 3

[0083] Example 3: Preparation of a short-circuit-proof top-emitting OLED device.

[0084] The specific operation steps are as follows:

[0085] (1) Substrate pretreatment: ordinary optical glass (effective area of 0.09cm 2 , namely 0.3cm×0.3cm) in acetone, absolute ethanol and deionized water for 20 minutes, followed by ultrasonic cleaning for 20 minutes, and drying at 150°C for 10 minutes;

[0086] (2) Evaporation of the aluminum layer in the anode: Cut a high-purity small aluminum block (about 5-6mm in diameter, purchased from alfa, with a purity of 99.999%) into small pieces of about 2-3mm square, and put them into the nitriding In the boron crucible, use tantalum skin to evaporate, adjust the current heating power, and control the evaporation rate to 0.3~0.5nm / s until the aluminum layer evaporated on the glass substrate reaches 50nm;

[0087] (3) Evaporation of the silver layer in the anode: use high-purity silver particles (about 1mm in diameter, purchased from alfa, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com