A flexible and bendable shape memory alloy actuator

A memory alloy and memory alloy wire technology, which is applied to machines/engines, mechanisms that generate mechanical power, mechanical equipment, etc., can solve the problems of inability to further reduce the volume size, inconvenient adjustment of parameters, and small output displacement, and achieve easy debugging. It is integrated with the installation, realizes parameter adjustment, and does not produce the effect of electromagnetic interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

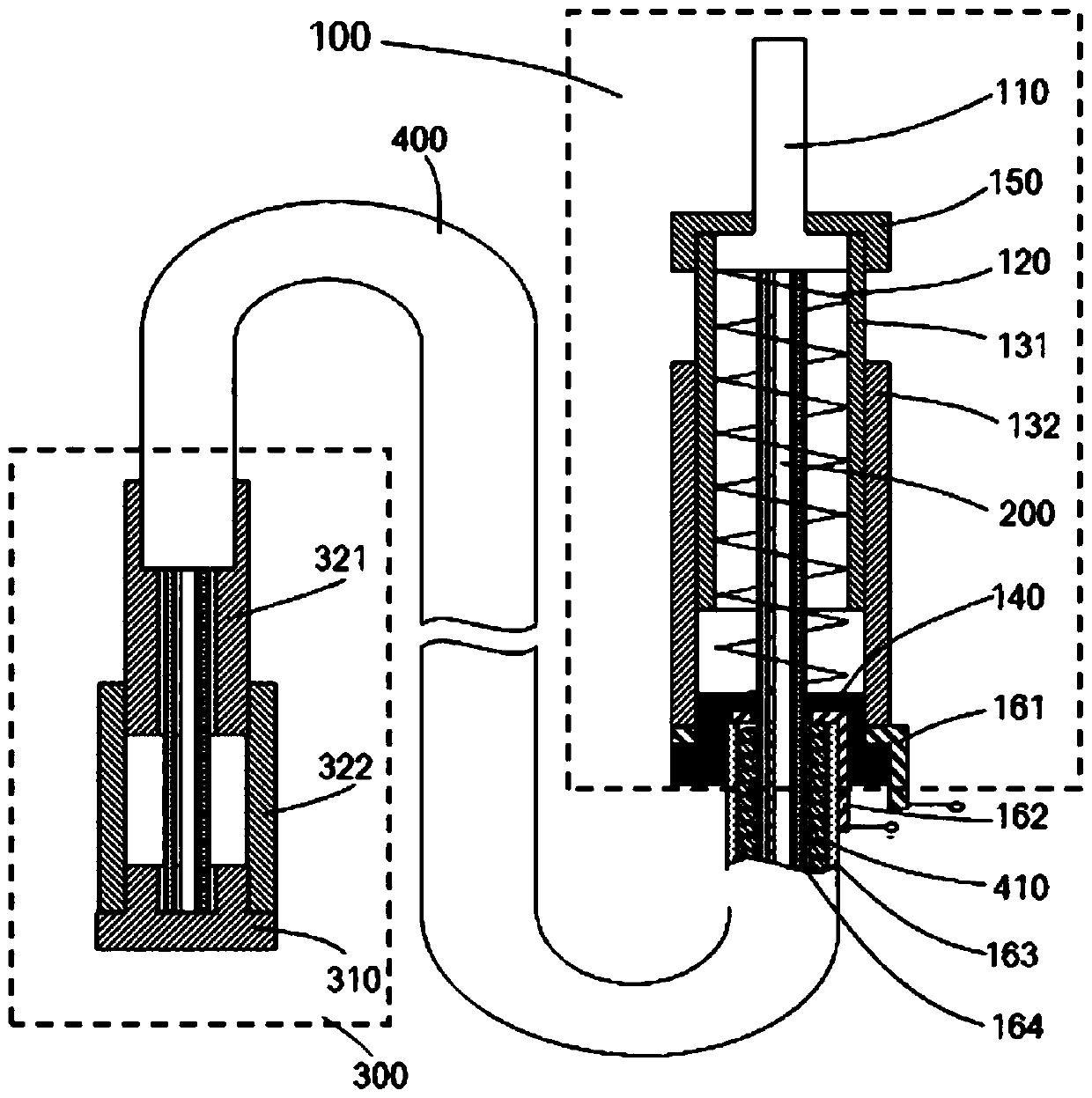

[0046] like figure 1 As shown, the present invention provides a flexible and bendable shape memory alloy driver, which includes: a shape memory alloy wire 200, and a driving end 100 for fixed connection with one end of the shape memory alloy wire 200 and the other end of the shape memory alloy wire 200 The fixed end 300, which is fixedly connected at one end, also includes a solenoid 410 wound around the shape memory alloy wire 200, the solenoid 410 and the shape memory alloy wire 200 can be folded and bent together and maintain the bent shape; wherein, the shape memory alloy The wire 200 can be nickel-titanium, copper-based or iron-based memory alloy material.

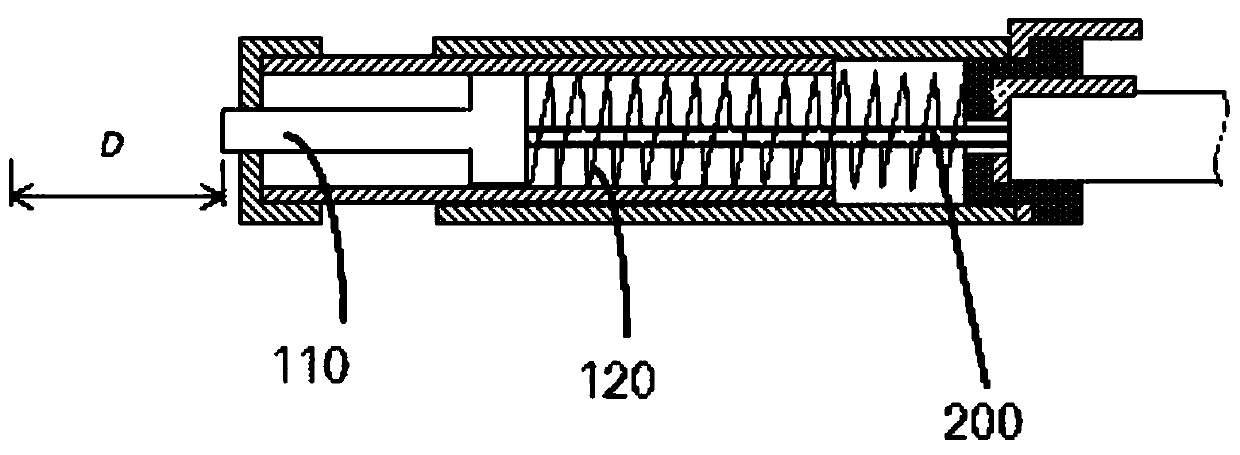

[0047] In another embodiment, such as figure 1 As shown, the driving end 100 includes a bias spring 120, a drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com