Method for preparation of antioxidant composite coating on carbon fiber surface

A composite coating and carbon fiber technology, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve problems such as cracks and peeling off of the coating, inconformity with energy conservation and environmental protection, and impact on oxidation resistance, etc., achieving shortened preparation time, Reduced equipment requirements and short aging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing an oxidation-resistant composite coating on a carbon fiber surface, comprising the steps of:

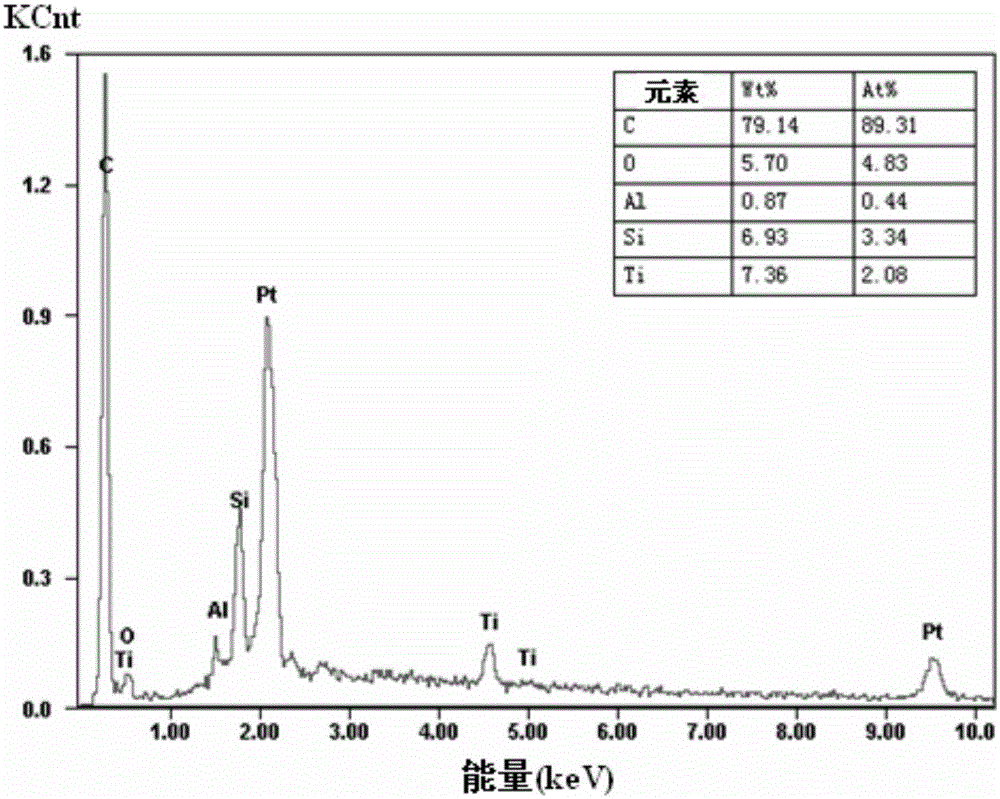

[0035] (1) Preparation of composite sol: the precursor ethyl orthosilicate (CAS#78-10-4), butyl titanate (CAS#5593-70-4), aluminum nitrate nonahydrate (CAS#7784-27 -2) prepare ternary composite sol according to Al:Si:Ti=1.5:4:0.5 (molar ratio), specifically:

[0036] a) Ethyl orthosilicate, acetic acid and distilled water were added to ethanol in sequence, and stirred at room temperature for 2 hours to obtain a mixed solution A, wherein: ethyl orthosilicate: ethanol: acetic acid: distilled water = 4:16:4: 11 (molar ratio); according to butyl titanate: ethanol = 1:8 (molar ratio), add butyl titanate to ethanol, stir at room temperature to mix them uniformly, and obtain an ethanol solution of butyl titanate; According to aluminum nitrate nonahydrate: ethanol=1:35 (molar ratio), join aluminum nitrate nonahydrate in ethanol, stir at room temperature to make...

Embodiment 2

[0046] The difference between this embodiment and Example 1 is only that: "Ultrasonic immersion for 90 minutes" in step (3) is replaced by "Ultrasonic immersion for 60 minutes", the rest of the content is the same as described in Example 1, and finally the surface coated with al 2 o 3 -SiO 2 -TiO 2 Carbon fiber with anti-oxidation composite coating, the thickness of the coating is about 0.55 μm; the prepared Al 2 o 3 -SiO 2 -TiO 2 Antioxidant composite coatings such as figure 1 Shown: Uniform and complete with good adhesion.

Embodiment 3

[0048] The difference between this example and Example 1 is that the "ultrasonic immersion for 90 minutes" in step (3) is replaced by "ultrasonic immersion for 60 minutes", and the carbon fiber is repeatedly coated and dried twice, and the step "Insulated at 750°C for 1 hour" in (4) was replaced with "insulated at 750°C for 1.5 hours", all the other contents were the same as those described in Example 1, and finally the surface was coated with Al 2 o 3 -SiO 2 -TiO 2 Carbon fiber with anti-oxidation composite coating, the thickness of the coating is about 1.17μm; the prepared Al 2 o 3 -SiO 2 -TiO 2 Antioxidant composite coatings such as figure 1 Shown: Uniform and complete with good adhesion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com