High performance dissimilar aluminum alloy welded joint containing nanocrystalline composite organization

A technology of dissimilar aluminum alloys and welded joints, which is applied in welding/welding/cutting articles, welding equipment, metal processing, etc., can solve the problems of reducing the performance of dissimilar aluminum alloy welded joints, and achieve simple and easy preparation process and excellent mechanical properties Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

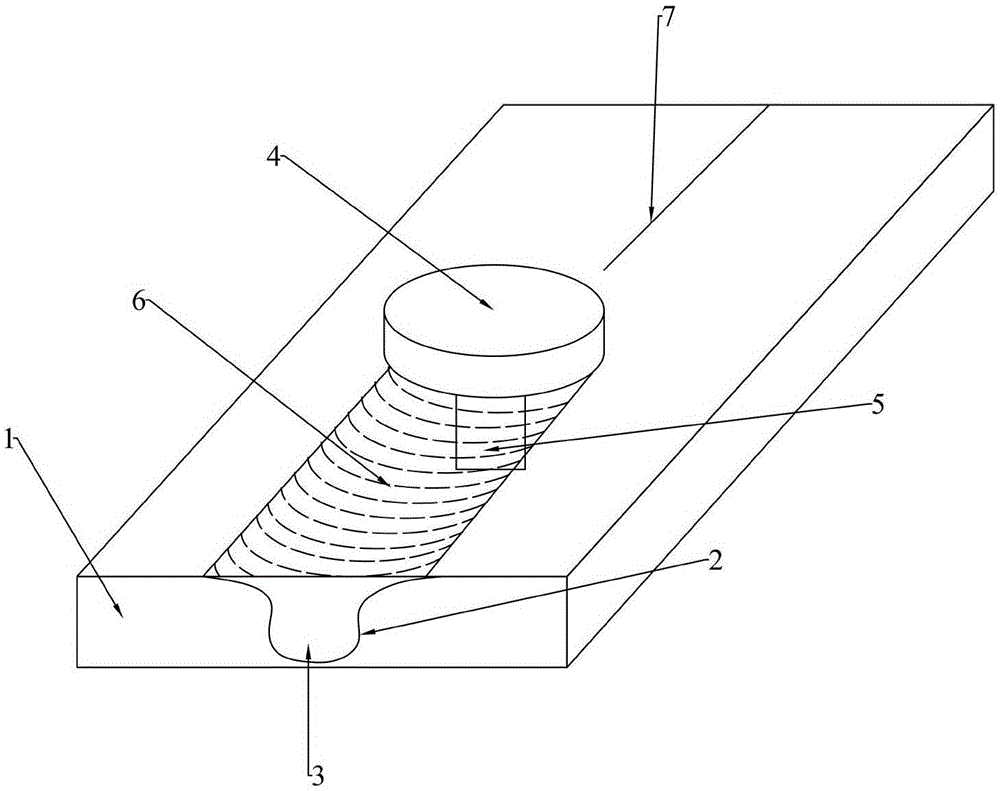

[0024] 1. Preparation of a high-performance dissimilar aluminum alloy welded joint containing nanocrystalline complex phase structure (see figure 1 , figure 2 )

[0025] Take two 5052-O and 6061-T6 aluminum plates, and turn the cross-section of the weld to make it smooth, so as to ensure that there is no gap between the two plates during welding. Afterwards, the surface of the sample was polished with a steel brush, and then two pieces of 5052-O and 6061-T6 aluminum plates with a size of 200×100×6 mm including butt joints were cut off. Place 6061-T6 on the forward side 2 of the welding table, 5052-O on the rotary side 1, and fix it with a fixture. Use a high-speed rotating conical stirring pin to pierce the aluminum plate and move along the welding direction 7. The heat generated by the rotating friction makes the Surrounding materials form a stirring zone 6, and the softened metals in the stirring zone form dissimilar aluminum alloy welded joints through interdiffusion and...

Embodiment 2

[0037] Adjust the welding process parameters, and use butt welding to weld 5052-O / 6061-T6 dissimilar aluminum alloys. The welding process parameters are shown in Table 2:

[0038] Table 2 Welding process parameters of high-performance dissimilar aluminum alloy welded joints containing nanocrystalline multiphase structure

[0039]

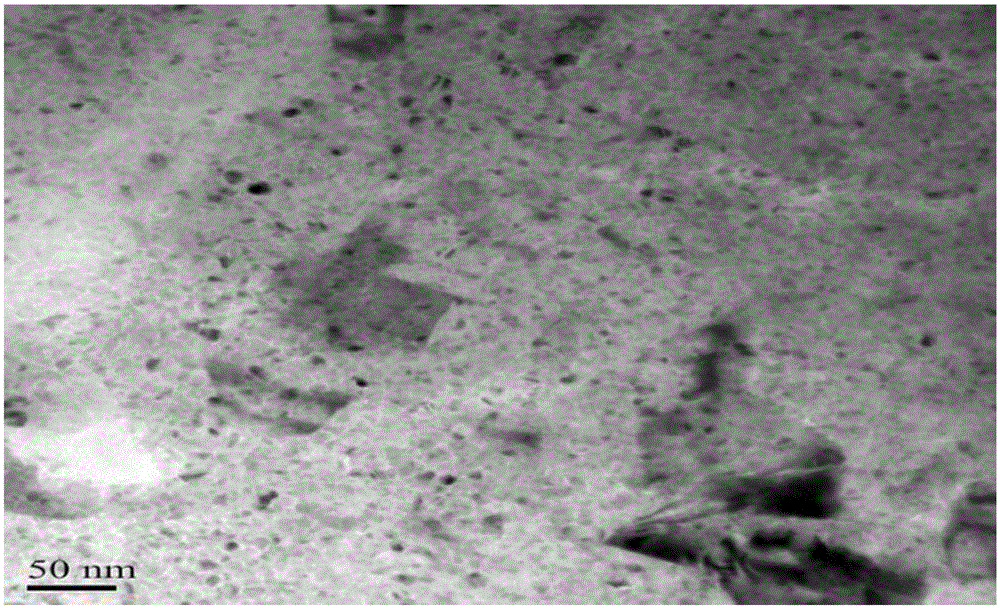

[0040]A well-formed 5052-O / 6061-T6 dissimilar aluminum alloy welded joint containing nanocrystalline multiphase structure was obtained. There were about 5nm nanocrystalline grains and dislocations in the weld nugget area, and the fracture morphology of the joint showed obvious micropore aggregation type fracture characteristics, showing good toughness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

| Top diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com