Composite coating fresh keeping agent containing hawthorn leaf flavone and preparation method and application thereof

A hawthorn leaf flavonoid and compound fresh-keeping technology, which is applied in the application, food preservation, food science and other directions, can solve the problems of lack of anti-oxidation and inhibition of microbial activities and other multi-functional comprehensive fresh-keeping effects, large chemical fresh-keeping residues, and safety doubts. , to achieve the effect of improving synergistic antioxidant and bacteriostatic activities, obvious fresh-keeping effect, and enhancing integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

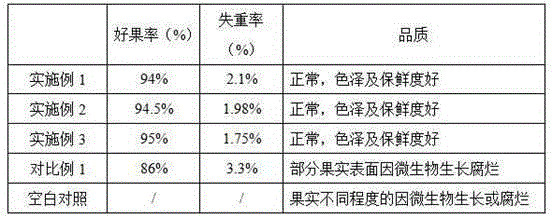

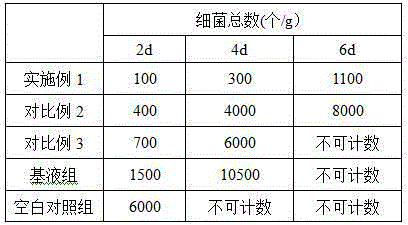

Examples

Embodiment 1

[0029] An extraction of hawthorn leaf flavonoids is characterized in that the following method is used to extract:

[0030] (1) Mix the powder of hawthorn leaves with 70vol% ethanol solution according to the ratio of material to liquid: 1g: 20mL, then add acetic acid to adjust the pH value to 4, stir evenly, add to the ultrasonic extractor, and heat up to 3°C / min. 50°C, under the condition of power of 500W, repeat the extraction three times, each time for 20min;

[0031] (2) Combine the extracts and filter, and when the filtrate is extracted with ethyl acetate until it becomes nearly transparent, remove the ethyl acetate layer with a separatory funnel, concentrate in a rotary evaporator, and freeze-dry to obtain hawthorn leaf flavonoids.

[0032] A compound preservative containing hawthorn leaf flavonoids extract, raw materials are:

[0033] Hawthorn leaf flavonoid extract 0.5 parts, carboxymethyl chitosan 30 parts, glycerin 30 parts, calcium chloride 5 parts, polyethylene gl...

Embodiment 2

[0040] A hawthorn leaf flavone is characterized in that it is extracted by the following method:

[0041] (1) Mix the powder of hawthorn leaves with 70vol% ethanol solution according to the ratio of material to liquid: 1g: 20mL, then add acetic acid to adjust the pH value to 4.5, stir well, add it to an ultrasonic extractor, and heat up to 4°C / min. 50°C, under the condition of power of 500W, repeat the extraction three times, each time for 20min;

[0042] (2) Combine the extracts and filter, and when the filtrate is extracted with ethyl acetate until it becomes nearly transparent, remove the ethyl acetate layer with a separatory funnel, concentrate in a rotary evaporator, and freeze-dry to obtain hawthorn leaf flavonoids.

[0043] A compound preservative containing hawthorn leaf flavonoids extract, raw materials are:

[0044] Hawthorn leaf flavonoid extract 0.95 parts, carboxymethyl chitosan 19 parts, glycerin 36 parts, calcium chloride 7.8 parts, polyethylene glycol (molecul...

Embodiment 3

[0047] A hawthorn leaf flavone is characterized in that it is extracted by the following method:

[0048] (1) Mix the powder of hawthorn leaves with 70vol% ethanol solution according to the ratio of material to liquid: 1g: 20mL, then add acetic acid to adjust the pH value to 5, stir evenly, add to the ultrasonic extractor, and heat up to 50°C, under the condition of power of 500W, repeat the extraction three times, each time for 20min;

[0049](2) Combine the extracts and filter, and when the filtrate is extracted with ethyl acetate until it becomes nearly transparent, remove the ethyl acetate layer with a separatory funnel, concentrate in a rotary evaporator, and freeze-dry to obtain hawthorn leaf flavonoids.

[0050] A compound preservative containing hawthorn leaf flavonoids extract, raw materials are:

[0051] Hawthorn leaf flavonoid extract 1.5 parts, carboxymethyl chitosan 10 parts, glycerin 40 parts, calcium chloride 10 parts, polyethylene glycol (molecular weight 600)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com