Silane treatment agent for metal surface

A silane treatment agent, metal surface technology, applied in the direction of metal material coating process, etc., can solve the problems of inconvenient transportation, storage, lack of concentration characteristics, poor environmental compatibility, etc., to achieve excellent adhesion performance, superior environmental protection performance, and improved performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The formula composition of metal surface silane treatment agent: 25 parts of N-(β-aminoethyl-γ-aminopropyl) methyldimethoxysilane, 30 parts of ethyl cellulose, 7 parts of sodium citrate, 15 parts of purified water share.

[0018] Table 1, working fluid technical index of embodiment one

[0019] serial number

project

index

1

technical indicators

Concentrate specific gravity: d=1.15±0.001

2

Exterior

light yellow transparent liquid

3

Groove dosage

Concentrate dosage: (kg / m 3 )0.2kg

4

Bath concentration

Spray PH value: 7.2

5

Processing temperature

6

processing time

Spray for 3 seconds

[0020] Table 2, the performance index of the film layer formed on the surface of 08f steel in embodiment one

[0021]

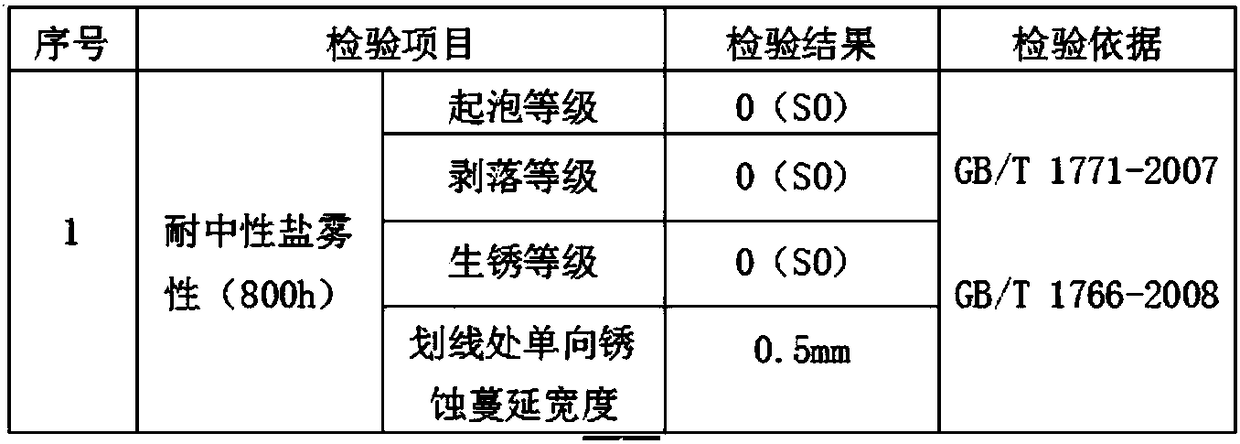

[0022] Table 3, the neutral salt spray resistance test table of the iron parts after the treatment of embodiment one

[0023]

Embodiment 2

[0025] The formula composition of metal surface silane treatment agent: 25 parts of N-(β-aminoethyl-γ-aminopropyl) methyldimethoxysilane, 25 parts of methyl cellulose, 6 parts of sodium citrate, 19 parts of purified water share.

[0026] Table 4, the working fluid technical index of embodiment two metal surface silane treatment agents

[0027]

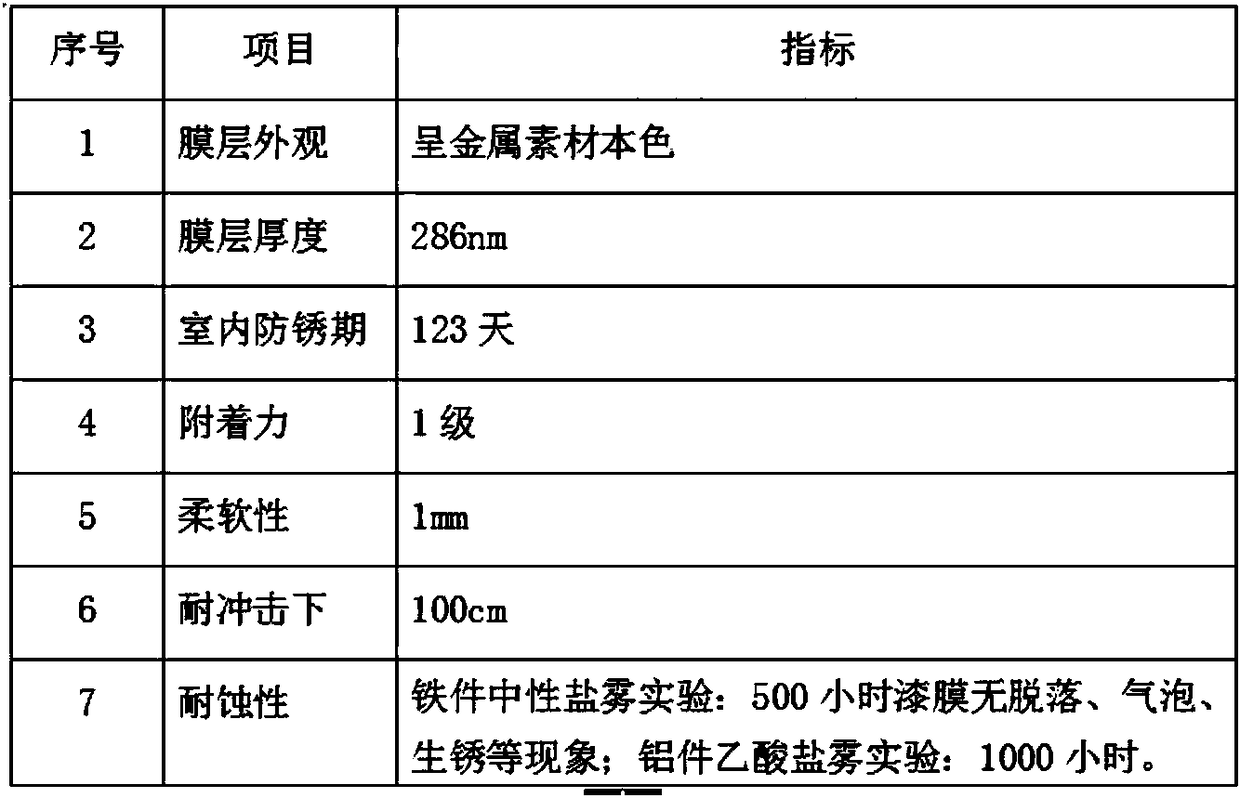

[0028] Table 5, the performance index of the film layer formed on the surface of 08f steel in embodiment two

[0029]

[0030] Table 6, six performance test tables of the aluminum sample plate after the treatment of embodiment two

[0031]

Embodiment 3

[0033] The formula composition of metal surface silane treatment agent: 27 parts of N-(β-aminoethyl-γ-aminopropyl) methyldimethoxysilane, 20 parts of ethyl cellulose, 7 parts of sodium citrate, 15 parts of purified water share.

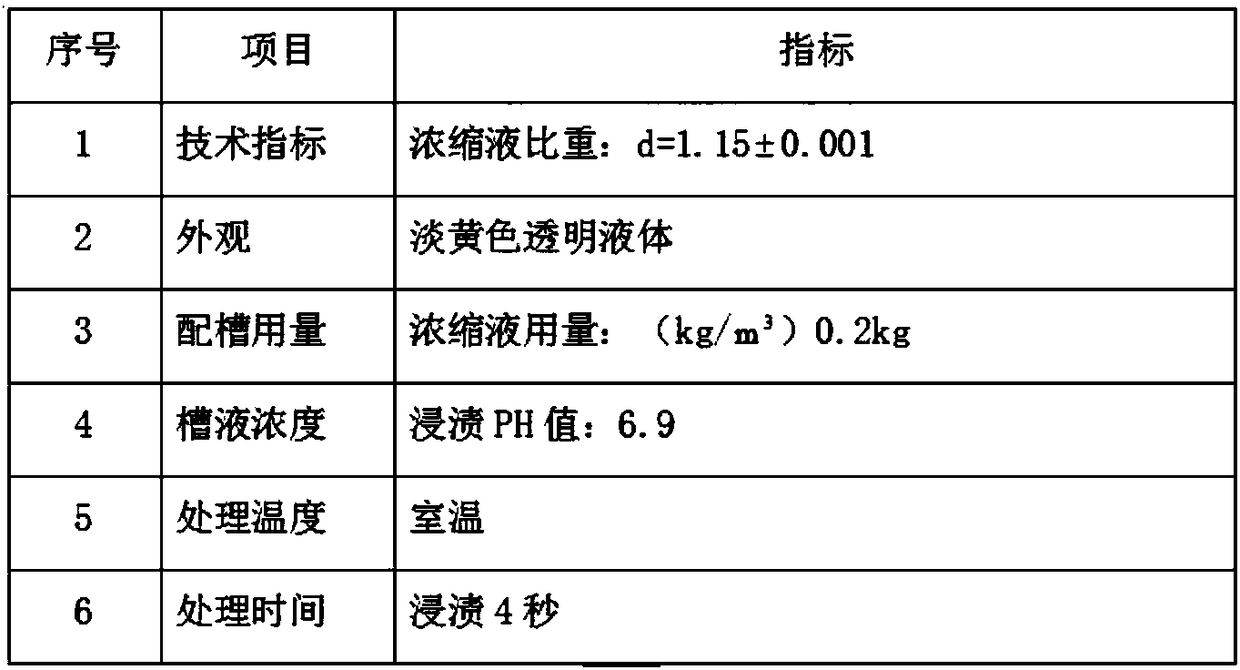

[0034] Table 7, the working fluid technical index of embodiment three

[0035] serial number

project

index

1

technical indicators

Concentrate specific gravity: d=1.15±0.001

2

Exterior

light yellow transparent liquid

3

Groove dosage

Concentrate dosage: (kg / m 3 )0.2kg

4

Bath concentration

Spray PH value: 7.3

5

Processing temperature

6

processing time

Spray for 4 seconds

[0036] Table 8, the performance index of the film layer formed on the surface of 08f steel in embodiment three

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com