LED epitaxial growth method for enhancing antistatic effect of device

An epitaxial growth, anti-static technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of weak anti-static ability, weakened anti-static ability, and poor crystal quality of LED devices, and achieve low dislocation density. , The effect of improving antistatic ability and improving crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

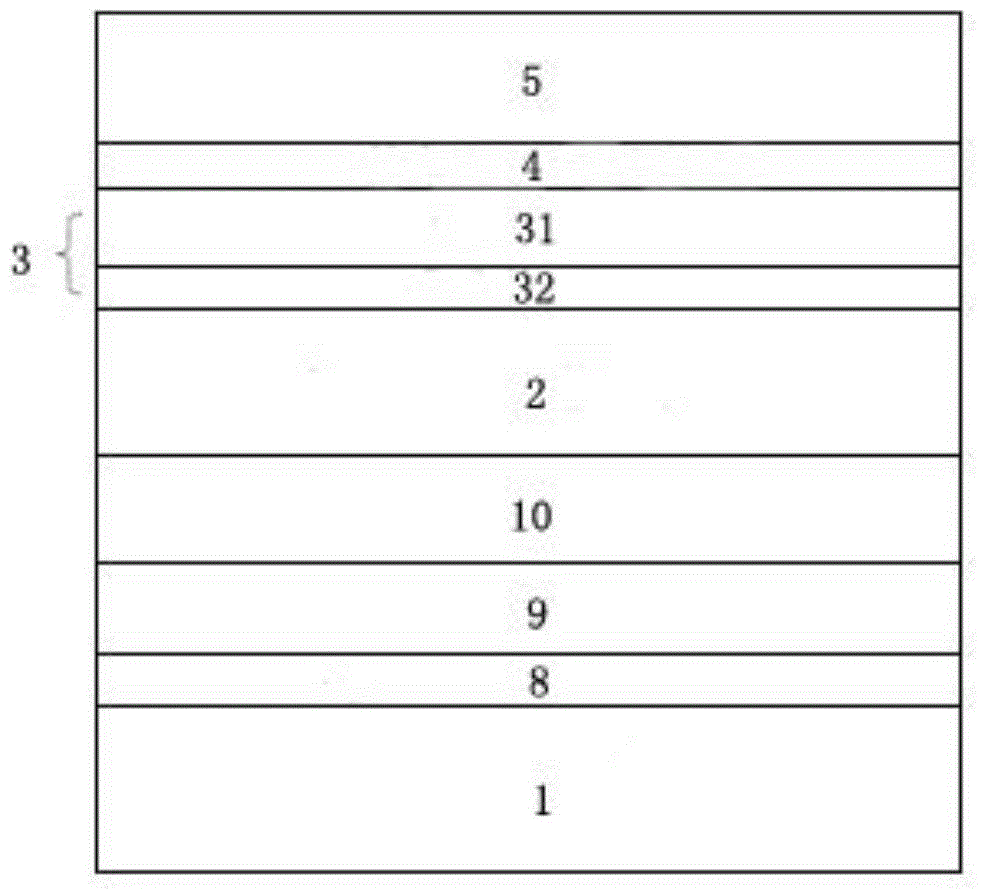

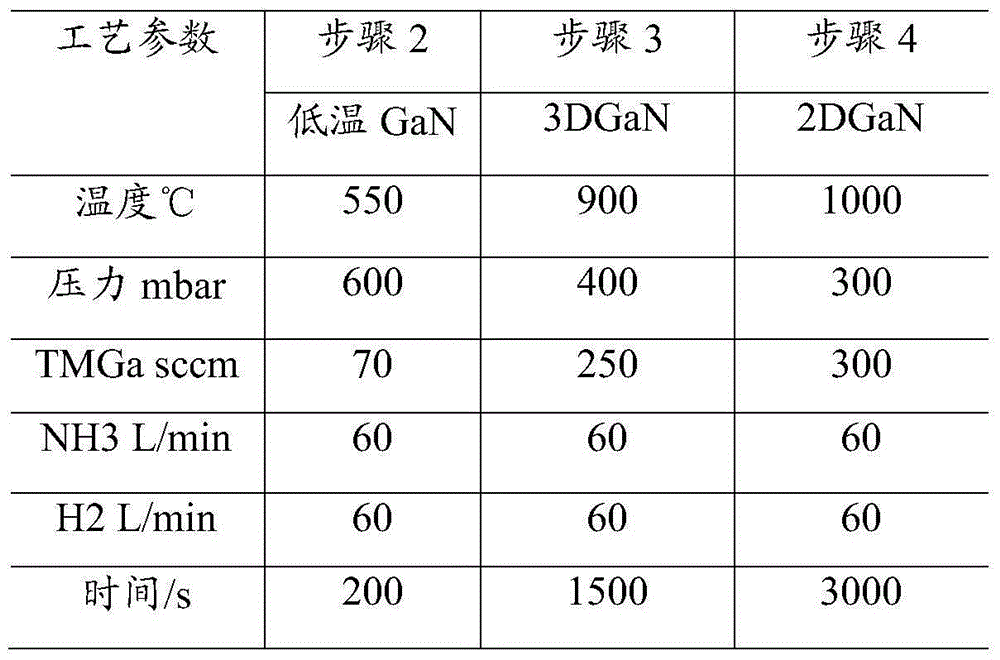

[0023] The invention uses MOCVD to grow high-brightness GaN-based LED epitaxial wafers. Use high-purity H2 or high-purity N2 or a mixture of high-purity H2 and high-purity N2 as the carrier gas, high-purity NH3 as the N source, metal organic source trimethylgallium (TMGa) as the gallium source, trimethylindium (TMIn ) as the indium source, the N-type dopant as silane (SiH4), trimethylaluminum (TMAl) as the aluminum source, the P-type dopant as magnesocene (CP2Mg), and the substrate as (0001) sapphire, the reaction The pressure is between 100mbar and 800mbar.

[0024] Step 101: maintaining the temperature at 900° C., maintaining the pressure in the reaction chamber at 100 mbar, and injecting 50 L / min of hydrogen gas to treat the sapphire substrate 1 at high temperature for 5 minutes;

[0025] Step 102: Maintaining the temperature at 700°C and maintaining the pressure in the reaction chamber at 100mbar, injecting 50L / min of hydrogen gas, 50L / min of ammonia gas, and 100 sccm of ...

Embodiment 2

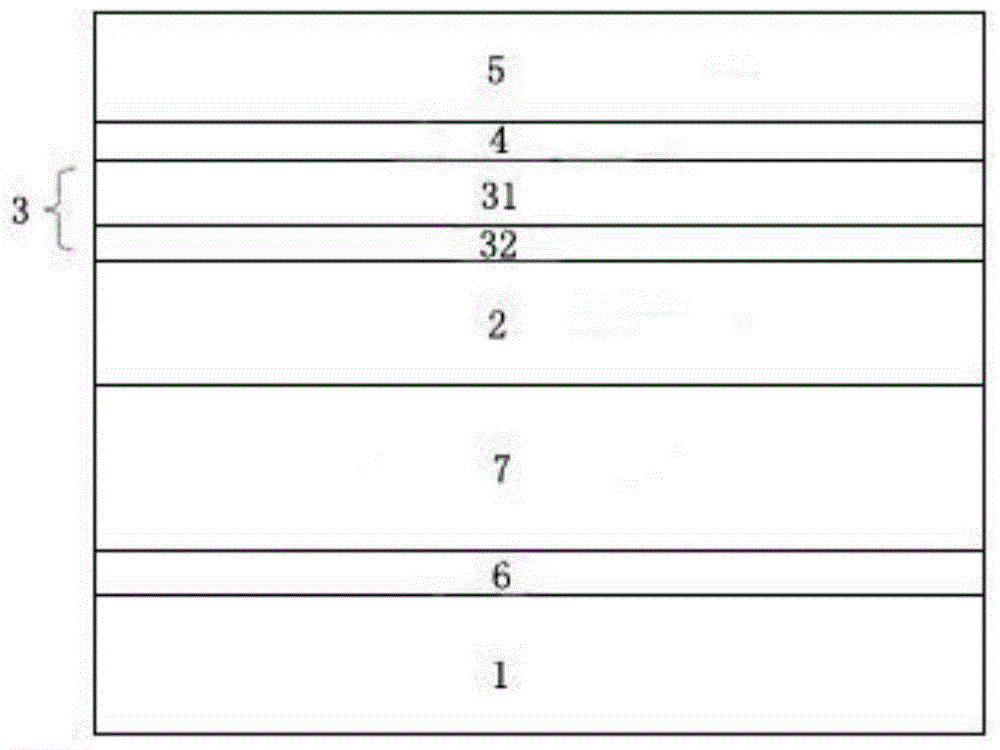

[0033] Step 201: maintaining the temperature at 1100° C., maintaining the pressure in the reaction chamber at 200 mbar, and injecting 100 L / min of hydrogen to treat the sapphire substrate 1 at high temperature for 10 minutes;

[0034] Step 202: maintaining the temperature at 800° C. and the pressure of the reaction chamber at 300 mbar, feeding 100 L / min of hydrogen gas, 100 L / min of ammonia gas, and 200 sccm of TMAl source to grow an AlN layer 6 with a thickness of 60 nm on the sapphire substrate;

[0035] Step 203: Raise the temperature to 900° C., maintain the pressure of the reaction chamber at 300 mbar, feed 100 L / min of hydrogen gas, 100 L / min of ammonia gas, 300 sccm of TMGa source, and 200 sccm of TMAl to continuously grow 5 μm of Al on the AlN layer 6 x Ga ( 1-x) N layer 7, the value range of x is between 0-1, which is 0.8 in this embodiment;

[0036] Step 204: Keep the temperature at 1100°C, maintain the pressure in the reaction chamber at 300mbar, feed 90L / min of hy...

Embodiment 3

[0042] Step 301: maintaining the temperature at 1000° C., maintaining the pressure in the reaction chamber at 150 mbar, and injecting 75 L / min of hydrogen gas to treat the sapphire substrate 1 at high temperature for 7 minutes;

[0043] Step 302: maintaining the temperature at 750° C. and the pressure of the reaction chamber at 200 mbar, feeding 75 L / min of hydrogen gas, 75 L / min of ammonia gas, and 150 sccm of TMAl source to grow an AlN layer 6 with a thickness of 40 nm on the sapphire substrate;

[0044] Step 303: Raise the temperature to 850° C., maintain the pressure of the reaction chamber at 200 mbar, feed 75 L / min of hydrogen gas, 75 L / min of ammonia gas, 250 sccm of TMGa source, and 125 sccm of TMAl to continuously grow 4 μm of Al on the AlN layer 6 x Ga (1-x) N layer 7, the value of x is 0.5;

[0045] Step 304: Keep the temperature at 1050°C, maintain the pressure in the reaction chamber at 225mbar, feed 70L / min of hydrogen, 50L / min of ammonia, 250sccm of TMGa source...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com