Strengthening, toughening and straightening process for deep hole machining gun-drill drill rod

A toughening and deep hole technology, which is applied in the coating process of metal materials, manufacturing tools, coatings, etc., can solve the technical requirements of investing a lot of manpower and material resources, failing to meet the performance requirements of parts, and the straightness of gun barrels failing to meet the design requirements and other issues, to achieve the effect of good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] as attached Figure 2-3 Shown, a kind of deep hole processing gun drill drill pipe strengthening and toughening and heat treatment straightening process may further comprise the steps:

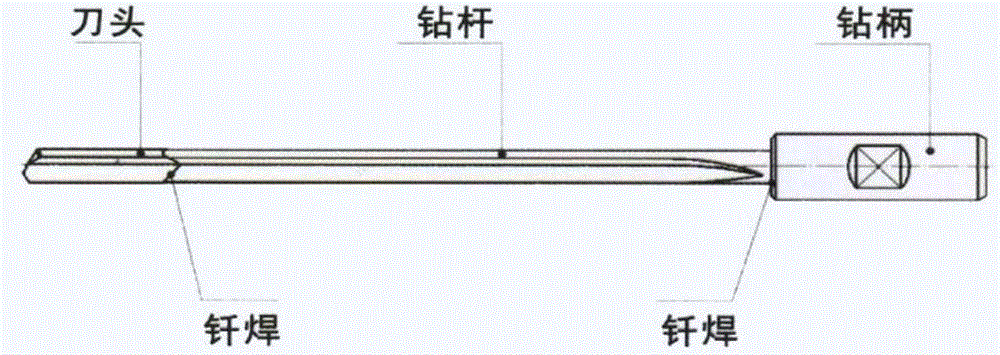

[0032] 1) Material selection, pipe making and molding

[0033] Select carburized steel, and make carburized steel into pipes of required specifications; then process and shape the pipes into deep hole processing gun drill rods before heat treatment;

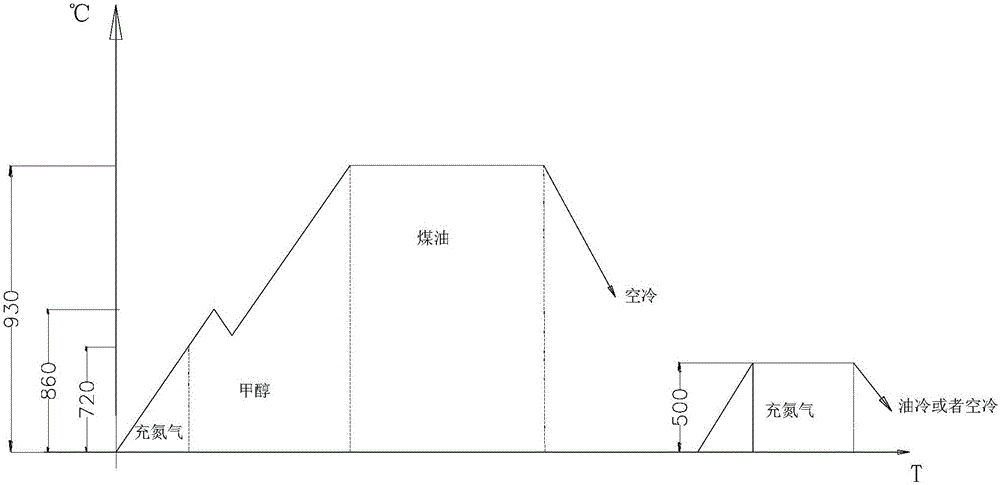

[0034] 2) Heat treatment strengthening and toughening and straightening integration

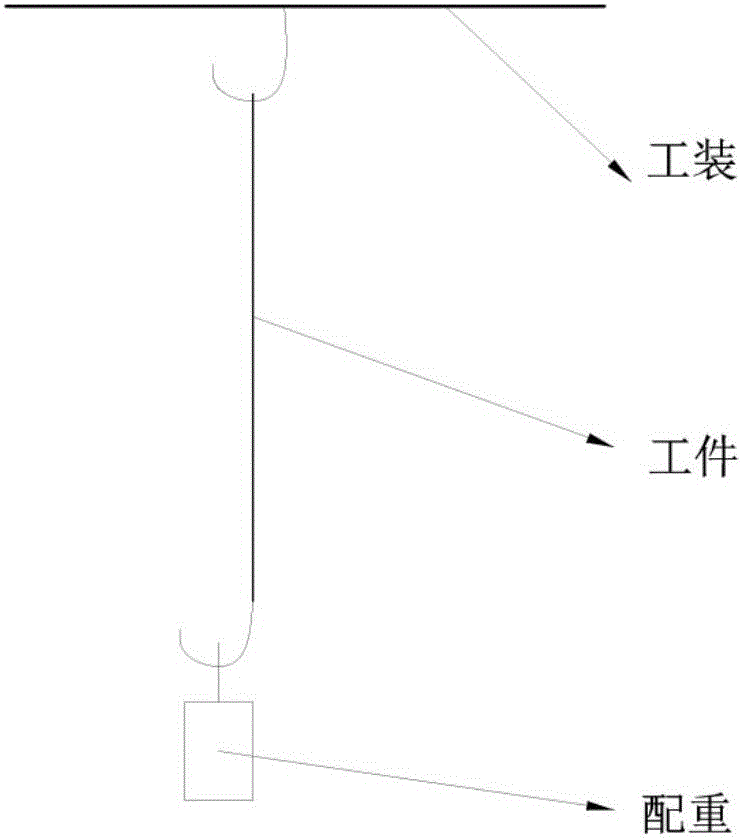

[0035] The deep-hole processing gun-drilling drill rod processed and formed by the carburizing steel before heat treatment is hung vertically on the tooling, and the bottom end of the deep-hole processing gun-drilling drill rod is mounted with a counterweight and sent into the deep well type gas carburizing furnace Medium carburizing, quenching, counterweight self-alignment;

[0036] 3) Tempering, straightening, cooling and forming

[0037] Tempering ...

Embodiment 2

[0044] as attached Figure 2-3 Shown, a kind of deep hole processing gun drill drill pipe strengthening and toughening and heat treatment straightening process may further comprise the steps:

[0045] 1) Material selection, pipe making and molding

[0046] Select carburized steel, and make carburized steel into pipes of required specifications; then process and shape the pipes into deep hole processing gun drill rods before heat treatment;

[0047] 2) Heat treatment strengthening and toughening and straightening integration

[0048] The deep-hole processing gun-drilling drill rod processed and formed by the carburizing steel before heat treatment is hung vertically on the tooling, and the bottom end of the deep-hole processing gun-drilling drill rod is mounted with a counterweight and sent into the deep well type gas carburizing furnace Medium carburizing, quenching, counterweight self-alignment;

[0049] 3) Tempering, straightening, cooling and forming

[0050] Tempering th...

Embodiment 3

[0058] as attached Figure 2-3 Shown, a kind of deep hole processing gun drill drill pipe strengthening and toughening and heat treatment straightening process may further comprise the steps:

[0059] 1) Material selection, pipe making and molding

[0060] Select high-quality alloy steel, and make high-quality alloy steel into pipes of required specifications; then process and shape the pipes into deep hole processing gun drilling drill pipes before heat treatment;

[0061] 2) Heat treatment strengthening and toughening and straightening integration

[0062] Hang the deep hole processing gun drill pipe before heat treatment vertically on the tooling, mount the counterweight on the bottom end of the deep hole processing gun drill pipe, and send it into the controllable gas protection furnace, vacuum furnace or high frequency furnace Heating and quenching, counterweight self-alignment;

[0063] 3) Tempering, straightening, cooling and forming

[0064] The strengthening and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com