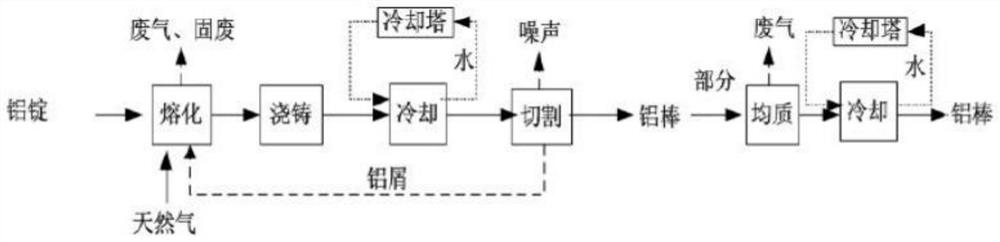

Aluminum profile casting process

An aluminum profile and process technology, applied in the field of aluminum profile processing, can solve problems such as affecting production, insufficient processing efficiency, and inability to accurately control the processing quality of aluminum alloy profiles, and achieve the effects of high quality and increased alloy content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] Batching and loading furnace: prepare materials according to the batching plan, and configure various materials required for production through weighing instruments according to the proportion of materials. First put the aluminum scrap into the melting and casting furnace for bottoming, so as to protect the bottom of the furnace from being damaged by large pieces of metal material, and then put in aluminum ingots, etc. Smelting: Close the furnace door to enter the smelting stage, use natural gas as fuel to melt into aluminum melt, the temperature is controlled at 750-780 ℃, and the time is about 4 hours.

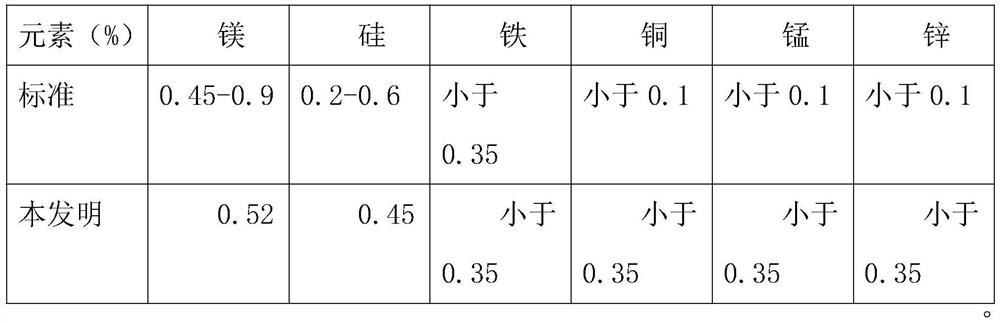

[0042] Slag removal: remove the scum on the surface of molten aluminum after smelting out of the furnace body, and improve the cleanliness of molten aluminum by manual slag removal. Adjusting the ingredients: After the slag removal is completed, add magnesium ingots, silicon ingots and other materials according to the process requirements, and stir evenly. If the ingr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com