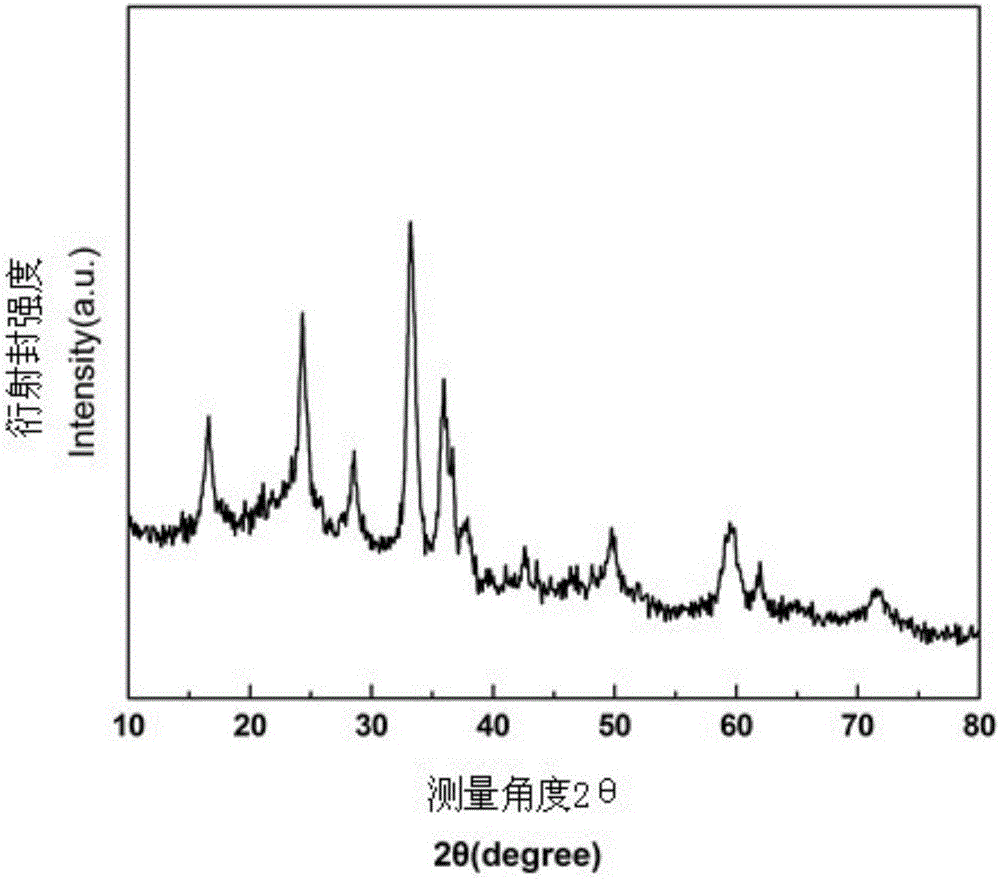

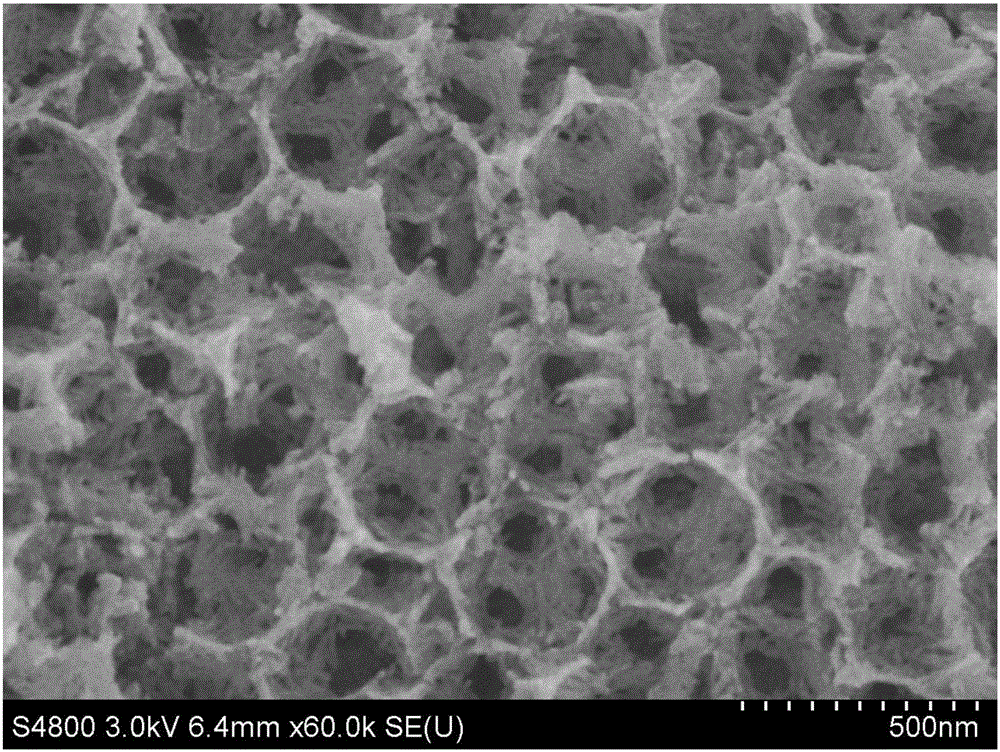

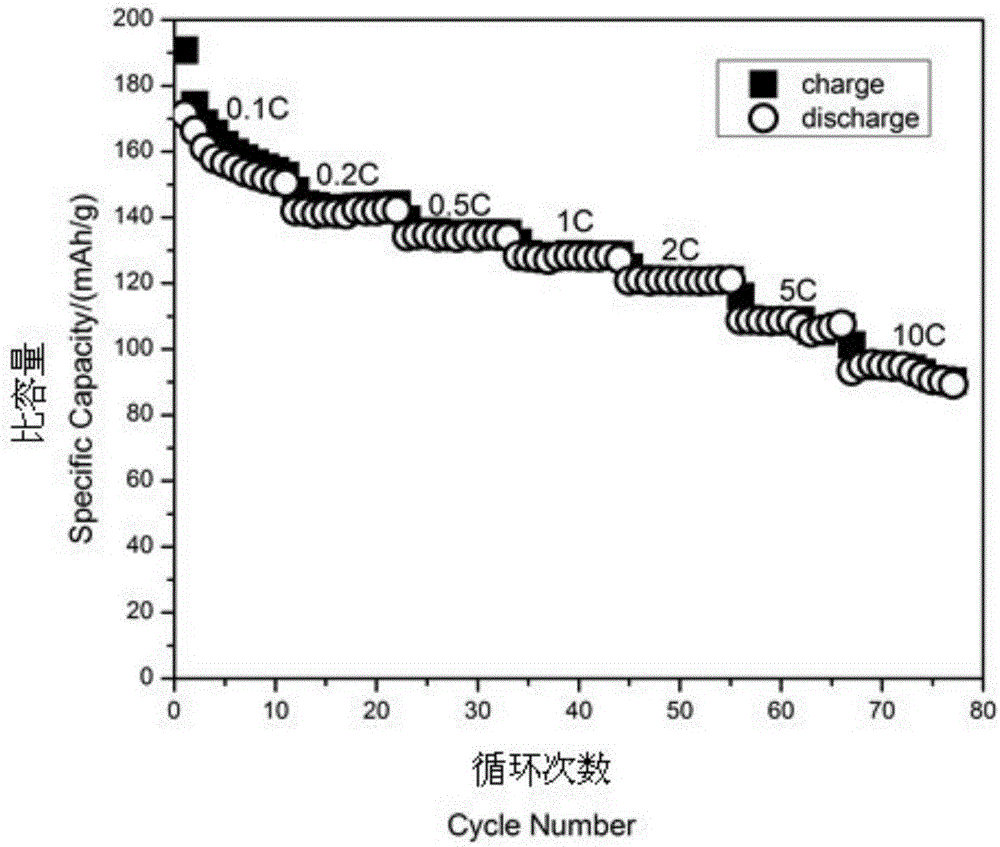

Meso-macroporous nano-fiber Li2FeSiO4 cathode active material

A positive active material and nanofiber technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of difficult to maintain close contact between particles, unfavorable power density, and impact on material tap density To achieve the effect of increasing the active interface of the electrochemical reaction, improving the kinetics of the electrode reaction, and improving the rate cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of mesoporous-macroporous nanofiber Li of the present invention 2 FeSiO 4 The preparation method of positive electrode active material, its specific steps are as follows:

[0033] Step 1, take by weighing 0.03g potassium persulfate respectively, be dissolved in the mixed solution of 100ml deionized water and 70ml ethanol, then drop 11ml styrene thereinto, react, generate polystyrene (PS) microsphere emulsion, And adopt gravity self-sedimentation method to assemble polystyrene (PS) colloidal crystal template;

[0034] Step 2, weigh 0.5g surfactant P 123 (EO 20 PO 70 EO 20 ), dissolved in 15mL ethanol to form the first solution; then weigh 2.088g ethyl orthosilicate, 0.02moL lithium nitrate and 0.01moL ferric nitrate and dissolve them in 10mL ethanol to form the second solution; add the second solution The first solution, under the condition of 40°C water bath, was stirred at a constant temperature to form Li 2 FeSiO 4 gel;

[0035] Step three, the Li 2 F...

Embodiment 2

[0037] A kind of mesoporous-macroporous nanofiber Li of the present invention 2 FeSiO 4 The preparation method of positive electrode active material, its specific steps are as follows:

[0038] Step 1, take 0.04g potassium persulfate respectively, dissolve it in the mixed solution of 100ml deionized water and 70ml ethanol, then add 11ml styrene dropwise to it, react, generate polystyrene microsphere emulsion, and adopt gravity Self-sedimentation method assembled into a colloidal crystal template;

[0039] Step 2, weigh 0.7g surfactant P 123 (EO 20 PO 70 EO 20 ), dissolved in 15mL ethanol to form the first solution; then weigh 2.088g ethyl orthosilicate, 0.02moL lithium nitrate and 0.01moL ferric nitrate and dissolve them in 10mL ethanol to form the second solution; add the second solution The first solution, under the condition of 40°C water bath, was stirred at a constant temperature to form Li 2 FeSiO 4 gel;

[0040] Step three, the Li 2 FeSiO 4 The gel was filled...

Embodiment 3

[0042]A kind of mesoporous-macroporous nanofiber Li of the present invention 2 FeSiO 4 The preparation method of positive electrode active material, its specific steps are as follows:

[0043] Step 1, take 0.05g potassium persulfate respectively, dissolve it in the mixed solution of 100ml deionized water and 70ml ethanol, then add 11ml styrene dropwise therein, react, generate polystyrene microsphere emulsion, and use gravity Self-sedimentation method assembled into a colloidal crystal template;

[0044] Step 2, weigh 0.8g surfactant P 123 (EO 20 PO 70 EO 20 ), dissolved in 15mL ethanol to form the first solution; then weigh 2.088g ethyl orthosilicate, 0.02moL lithium nitrate and 0.01moL ferric nitrate and dissolve them in 10mL ethanol to form the second solution; add the second solution The first solution, under the condition of 40°C water bath, was stirred at a constant temperature to form Li 2 FeSiO 4 gel;

[0045] Step three, the Li 2 FeSiO 4 The gel was filled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com