Micro fluidic electro-spray chip device and manufacture method

An electrospray and microfluidic technology, applied in electrical components, electrode system manufacturing, discharge tube/lamp manufacturing, etc., to improve repeatability, stability and reliability, facilitate manufacturing, and overcome non-uniformity problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

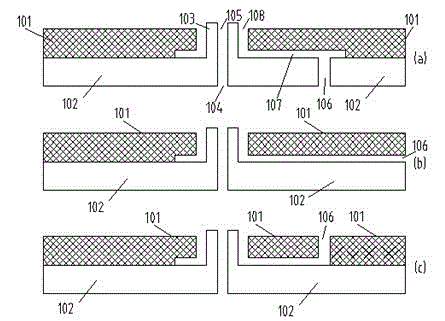

[0036] The structure of a specific embodiment of the present invention is as figure 1 As shown in (a), the liquid chip 102 has two substantially parallel surfaces, one is the liquid inlet surface and the other is the liquid outlet surface; there is at least one liquid inlet hole 104 on the liquid inlet surface for the liquid to flow in; the liquid outlet surface has at least An outlet hole 105 allows liquid to flow out; the inlet hole 104 and the outlet hole 105 are in fluid communication. On the liquid outlet surface, a region around the liquid outlet hole 105 is etched to a depth perpendicular to the liquid chip 102, so that a tubular electrospray nozzle 103 is formed at the liquid outlet hole 105; the gas chip 101 has two substantially parallel Two surfaces, one is the air inlet surface, and the other is the air outlet surface; there is at least one air outlet perforation 108 between the air inlet surface and the air outlet surface; there are etched grooves 107 on the air i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com