Coke oven ascension pipe raw gas evaporative cooling device and preparation method thereof

A technology of vaporization cooling and cooling device, which is applied to the vaporization cooling device of raw gas in the riser pipe of a coke oven and its preparation field, and can solve problems such as difficulty in long-term stable operation, cracking of weld seams of recovery device, temperature variation range and difference in quenching and quenching heating speed, etc. To achieve the effect of improving the comprehensive integrity and structural strength, homogenizing the temperature distribution of the substrate, and improving the efficiency of waste heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

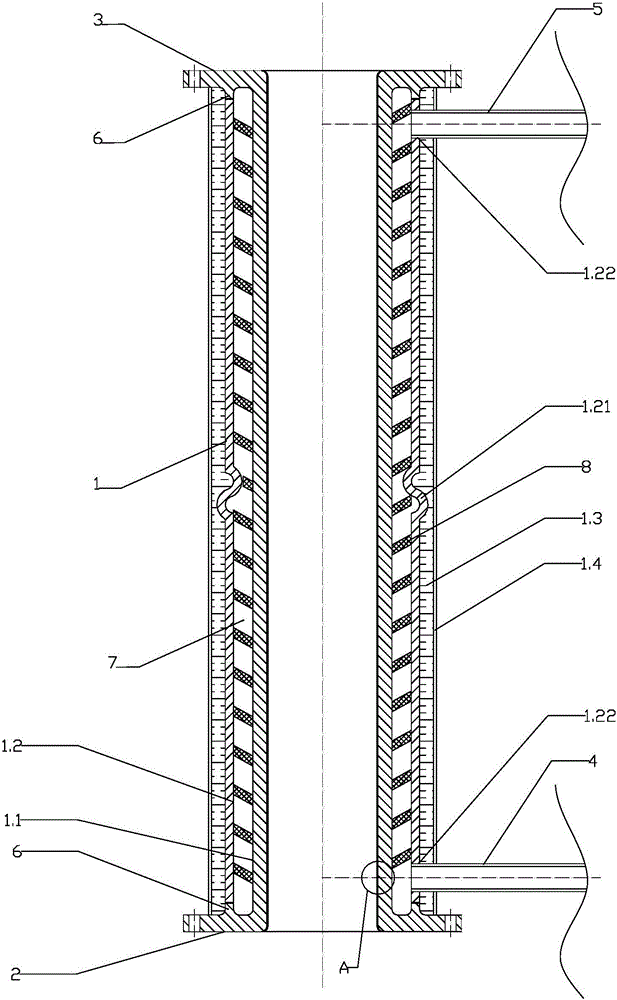

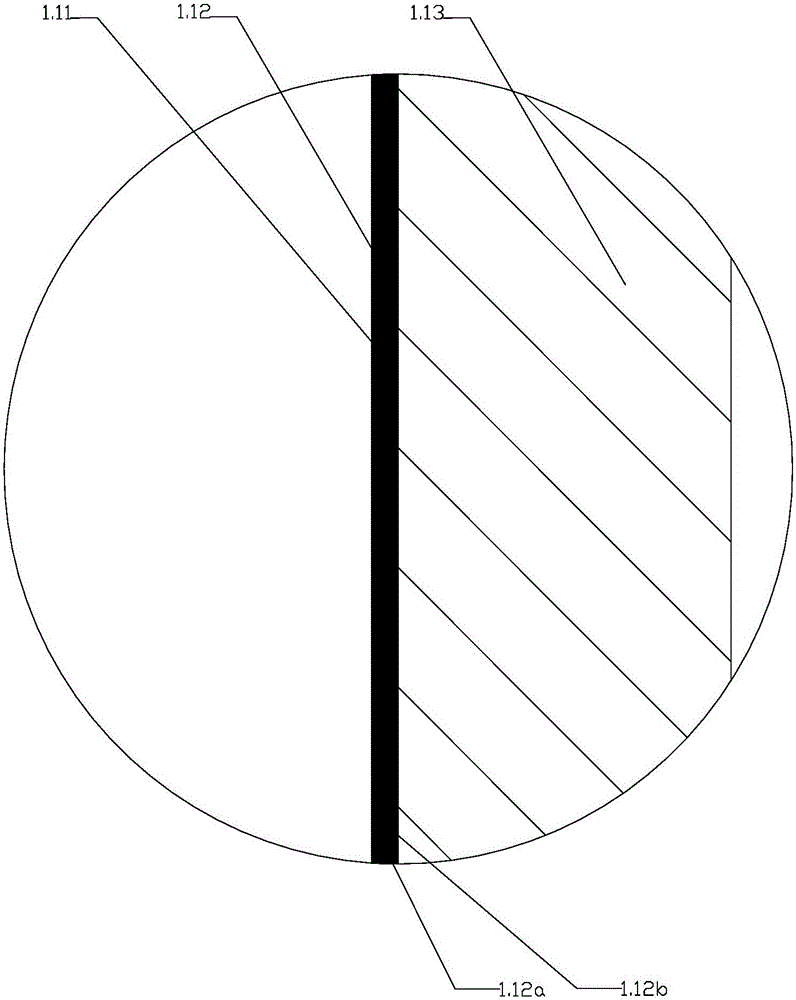

[0041] Such as figure 1 , 3 Shown in and 4: a coke oven ascending pipe raw gas vaporization cooling device, the cooling device includes a cooling pipe 1 and a raw gas inlet flange 2 and a raw gas outlet flange 3 respectively connected to the two ends of the cooling pipe 1, the cooling pipe 1 From the inside to the outside, it is composed of an inner casing 1.1, an outer casing 1.2, an insulation layer 1.3 and a protective layer 1.4. The inner casing 1.1 is composed of a high-temperature infrared radiation glaze layer 1.11, a thermal barrier coating 1.12 and an inner casing from the inside to the outside. The steel structure layer 1.13 is composed of a multi-layer material composite structure, and the two ends of the side wall of the outer casing 1.2 are respectively provided with through holes 1.22, and a water inlet steel pipe 4 is installed on the through hole 1.22 close to the raw gas inlet flange 2, which is close to the raw gas outlet A water vapor outlet steel pipe 5 is...

Embodiment 2

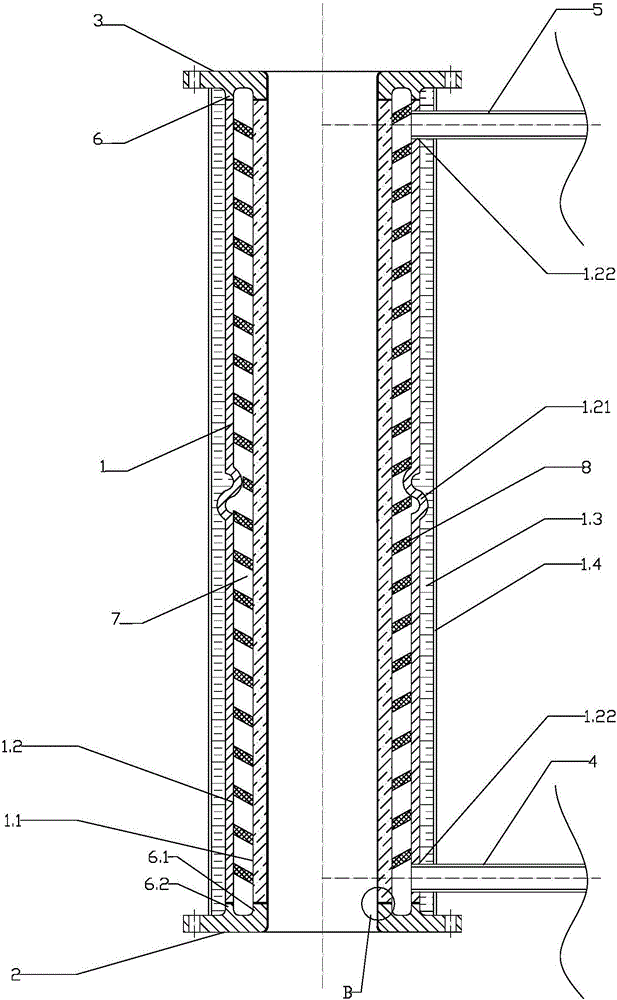

[0061] Such as figure 2 , 3 A coke oven riser raw gas vaporization cooling device shown in 4, the structure of this device is basically the same as that of the cooling device in Example 1, the difference is:

[0062] The raw gas inlet flange 2 and the raw gas outlet flange 3 have a double-circle annular boss 6. The double-circle annular boss 6 is composed of an inner ring annular boss 6.1 and an outer ring annular boss 6.2 arranged opposite to each other. The planes of the boss side and the raw gas inlet flange 2 and the raw gas outlet flange 3 are arc transitions. The 1.13 layer of the inner steel structure is made of 1Cr18Ni9Ti or Cr25Ni20 heat-resistant steel pipe, and the top surfaces of the inner ring boss 6.1 and the outer ring boss 6.2 are welded to the corresponding inner casing 1.1 and outer casing 1.2 respectively.

[0063] The raw gas inlet flange 2 and the raw gas outlet flange 3 have annular bosses 6 arranged in opposite directions in double circles, and are re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com