Environment-friendly metal surface treatment agent

A technology of metal surface treatment and treatment agent, applied in the direction of metal material coating process, etc., can solve the problems of corrosion resistance, insufficient coating adhesion, insufficient corrosion resistance, etc., and achieve excellent corrosion resistance and coating tightness. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

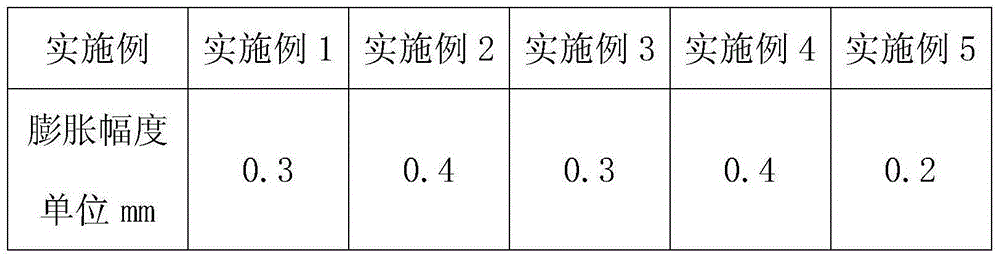

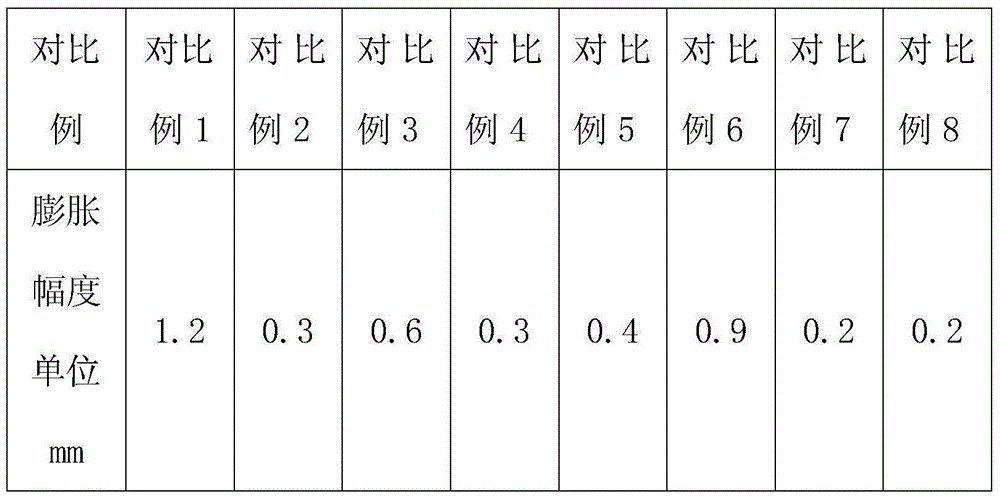

Examples

Embodiment 1

[0023] Prepare a cold-rolled plate sample block with the grade Q225, the size of which is 150mm×80mm×1mm.

[0024] In the first step of degreasing treatment, the metal material was degreased at 40° C. for 10 minutes using German Henkel RT-1022 degreasing agent.

[0025] In the second step of water washing, the sample block is sprayed and cleaned with deionized water for 30 seconds.

[0026] The third step is chemical conversion treatment.

[0027] Slowly add 25 parts of 1,2-bis(triethoxysilyl)ethane into 75 parts of deionized water, stir evenly, and react at 25°C for 24 hours for later use. Dissolve ammonium fluorozirconate, fluorotitanic acid, prepared 1,2-bis(triethoxysilyl)ethane hydrolyzate, ammonium molybdate, and magnesium nitrate in deionized water in sequence, and the concentrations of fluorozirconic acid Ammonium 1g / L, fluorotitanic acid 1g / L, 1,2-bis(triethoxysilyl)ethane 3g / L, ammonium molybdate 0.5g / L, magnesium nitrate 3g / L, mix and stir evenly, use Nitric acid...

Embodiment 2

[0032] Slowly add 25 parts of 1,2-bis(triethoxysilyl)ethane into 75 parts of deionized water, stir evenly, and react at 25°C for 24 hours for later use. Dissolve ammonium fluorozirconate, fluorotitanic acid, prepared 1,2-bis(triethoxysilyl)ethane hydrolyzate, ammonium molybdate, and magnesium nitrate in deionized water in sequence, and the concentrations of fluorozirconic acid Ammonium 2g / L, fluorotitanic acid 2g / L, 1,2-bis(triethoxysilyl)ethane 1g / L, ammonium molybdate 0.5g / L, magnesium nitrate 3g / L, mix and stir evenly, use Adjust the pH to 4 with nitric acid and ammonia water.

[0033] The sample block was immersed in the prepared metal surface treatment agent, the treatment temperature was controlled at 25°C, and the treatment time was 90 seconds.

[0034] Other steps are the same as in Embodiment 1.

Embodiment 3

[0036] Slowly add 25 parts of 1,2-bistrimethoxysilylethane into 75 parts of deionized water, stir evenly, and react at 25°C for 24 hours for later use. Dissolve ammonium fluorozirconate, fluorotitanic acid, prepared 1,2-bistrimethoxysilylethane hydrolyzate, ammonium molybdate, and magnesium nitrate in deionized water in sequence, the concentration of which is 1.5 g of ammonium fluorozirconate / L, 1.5g / L of fluorotitanic acid, 1g / L of 1,2-bistrimethoxysilylethane, 0.5g / L of ammonium molybdate, 2.5g / L of magnesium nitrate, mix well, and use nitric acid and ammonia water Adjust the pH to 4.

[0037] The sample block was immersed in the prepared metal surface treatment agent, the treatment temperature was controlled at 25°C, and the treatment time was 90 seconds.

[0038] Other steps are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com