A water glass precision casting process

A technology of precision casting and water glass, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems such as difficult to guarantee the surface quality, achieve the effect of reducing the workload of post-processing, reducing production costs, and improving the yield of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

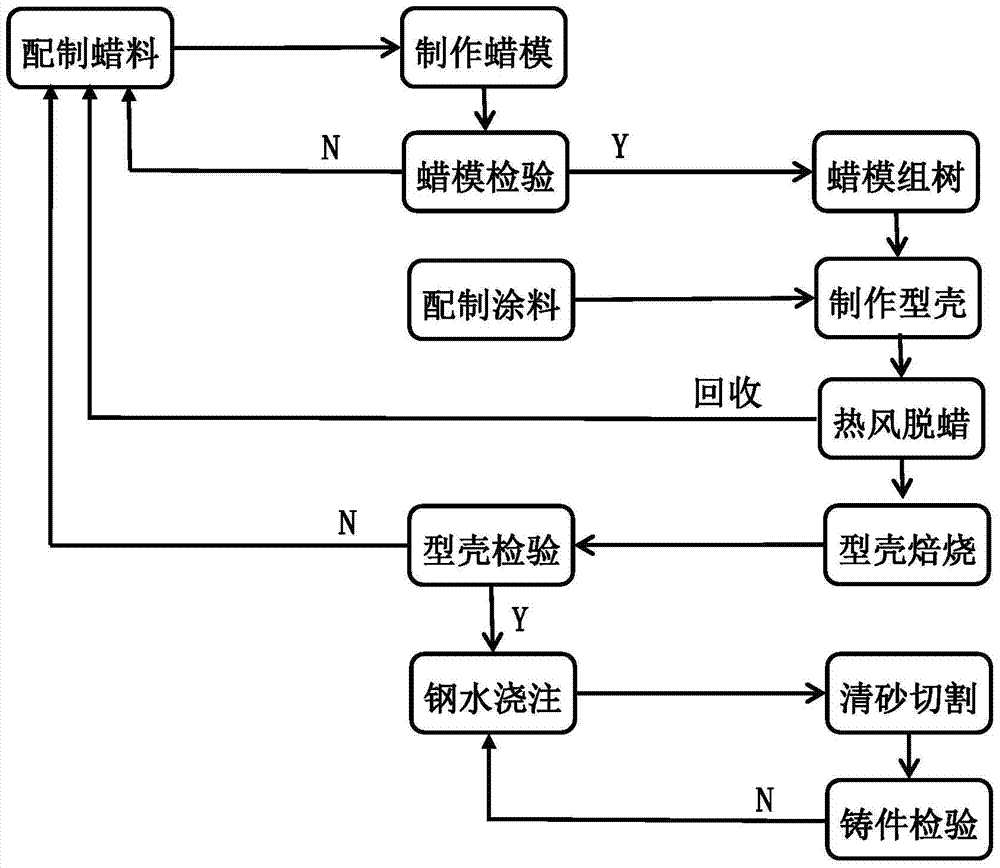

[0027] like figure 1 Shown, a kind of water glass method investment casting technique is characterized in that comprising the following steps:

[0028] The water glass method investment casting process includes the following steps:

[0029] 1) Preparation of wax material: heat, melt and stir paraffin wax and stearic acid in a mass ratio of 1:1 until they are evenly mixed into a paste, and the heating temperature is 80-89°C;

[0030] 2) Make wax mold: Pour the pasty wax material that has completed step 1) into the mold for wax injection, after pressure maintaining and cooling, take out the wax mold and put it in water in time to continue cooling;

[0031] 3) Wax model inspection: Use compressed air to clean the wax residue and residual water on the surface of the wax model that has completed step 2, use a trimming knife to remove the drape and protrusions on the parting surface, and use thin wax to fill in the defects and make it smooth ;

[0032] 4) Wax model group tree: Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com