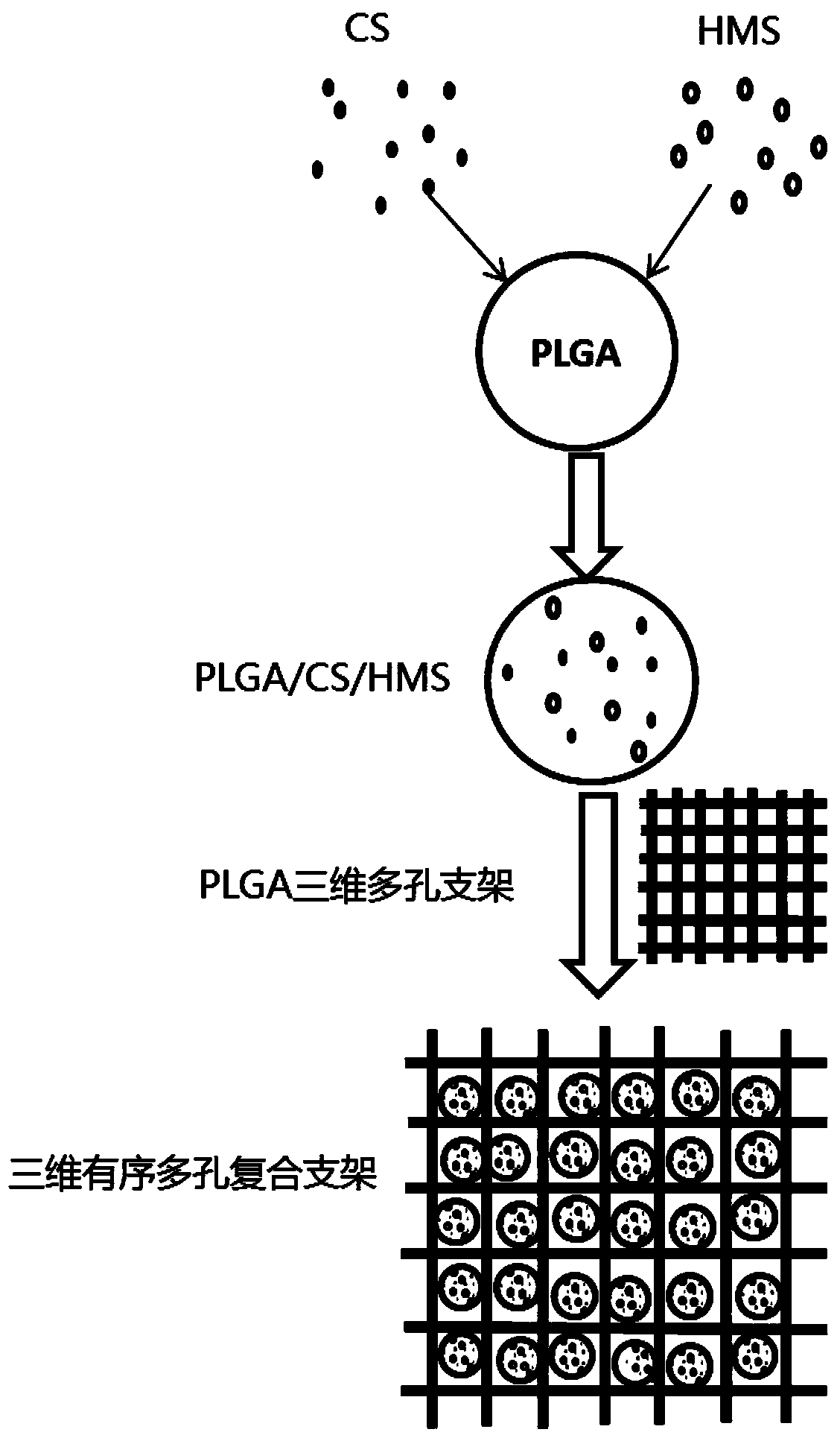

Porous composite scaffold for bone repair based on 3d-bioplotter printing technology and its preparation method

A composite scaffold and bone repair technology, applied in the field of biomedical engineering and biomedical materials, can solve the problems of inability to make large pore size, cytotoxicity, small porosity, etc., achieve good drug loading and drug release performance, and simple preparation process Quick, improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Prepare a PLGA cube support matrix with a regular three-dimensional macroporous structure:

[0046] Use the Bioplotter RP software to perform hierarchical processing on the STL format data of the cube model with a length of 10mm, a width of 10mm, and a height of 2mm, add 2gPLGA to the stainless steel barrel, select a needle of 0.3mm, open the VisualMachines software, set the printing temperature to 150°C, and the platform temperature The temperature is 25°C, the extrusion pressure is 1.5bar, the extrusion speed is 3mm / s, the internal structure is set to alternate between 0° and 90° of the nozzle, the layer thickness is 0.24mm, and the hole diameter is 1.2mm, and then the material is heated to the specified After keeping the temperature for 30 minutes, start the 3D-Bioplotter to print the three-dimensional structure model layer by layer, forming a regular three-dimensional macroporous structure in the CAD model. The PLGA cube support matrix, such as Figure 4 ;

[0...

Embodiment 2

[0052] (1) Preparation of a PLGA cylindrical scaffold matrix with a regular three-dimensional macroporous structure:

[0053] Use the Bioplotter RP software to process the STL format data of the cylinder model with a diameter of 10mm and a height of 2mm in layers, add 2gPLGA into the stainless steel barrel, select a 0.2mm needle, open the VisualMachines software, set the printing temperature to 150°C, and the platform temperature The temperature is 25°C, the extrusion pressure is 3.0bar, and the extrusion speed is 2mm / s. The internal structure is set to alternate nozzles at 0°, 45°, 90°, and 145°, the layer thickness is 0.16mm, and the hole diameter is 1.0mm. Then heat the material to the specified temperature and keep it warm for 30 minutes, start the 3D-Bioplotter to print the three-dimensional structure model layer by layer, and form a PLGA cylindrical support matrix with a regular three-dimensional macroporous structure in the CAD model;

[0054] (2) Preparation of PLGA / CS...

Embodiment 3

[0059] (1) Preparation of a polycaprolactone (PCL) cube scaffold matrix with a regular three-dimensional macroporous structure:

[0060] Use the Bioplotter RP software to process the STL format data of the cube model with a length of 10mm, a width of 10mm, and a height of 2mm. The temperature is 25°C, the extrusion pressure is 1.2bar, the extrusion speed is 3mm / s, the internal structure is set to alternate between 0° and 90° of the nozzle, the layer thickness is 0.32mm, and the hole diameter is 1.2mm, and then the material is heated to the specified After keeping the temperature for 30 minutes, start the 3D-Bioplotter to print the three-dimensional structure model layer by layer, forming the regular three-dimensional macroporous structure of the PCL cube support matrix in the CAD model;

[0061] (2) Preparation of PLGA / CS / HMS composite microspheres loaded with isoniazid:

[0062] Mix 30mg of isoniazid and 1g of hexagonal mesoporous silicon with an average pore diameter of 2.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com