A kind of femtosecond laser regulation ge m sb n te k Crystalline Nanostructure Geometry Method

A femtosecond laser and nanostructure technology, applied in the field of femtosecond laser applications, can solve problems such as harsh processing conditions, and achieve the effect of good optical response and optimized optical response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

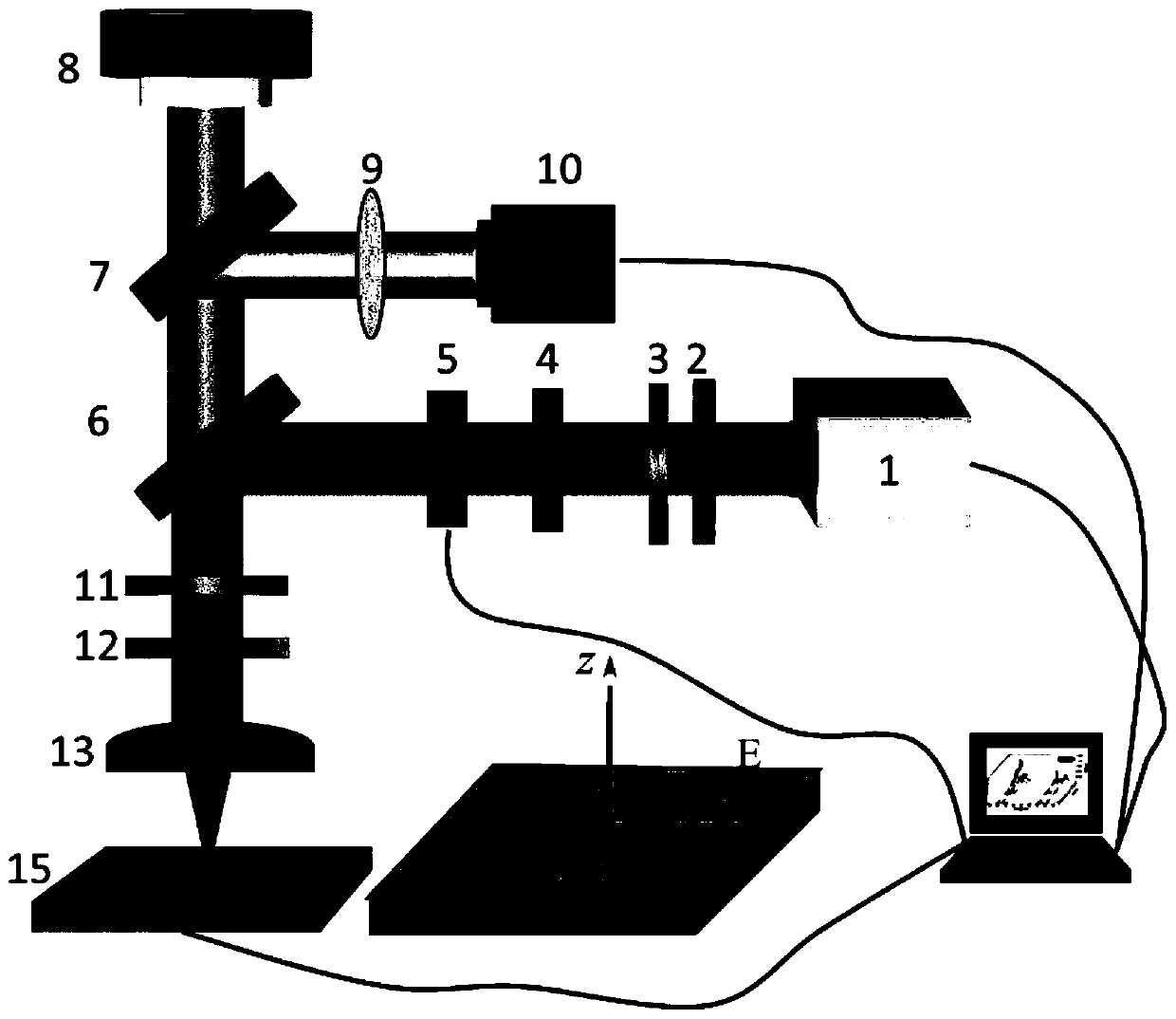

[0035] To process different forms of crystalline Ge 2 Sb 2 Te 5 Taking the all-dielectric composite nanostructure with anisotropic geometric form as an example, the multi-pulse femtosecond laser control method of the present invention is adopted, and the femtosecond laser pulses used are linearly polarized. The specific processing steps are as follows:

[0036] Adjust the optical path to ensure that the incident direction of the laser is perpendicular to the surface of the processed sample;

[0037] (1) Sample preparation: In this example, 50nm thick Ge was plated on a 10mm×10mm×1mm silicon dioxide sample by magnetron sputtering. 2 Sb 2 Te 5 membrane;

[0038] (2) Adjust energy: use the combination of the first half-wave plate 2 and the polarizer 3 and the neutral density attenuation plate 4 to adjust the laser energy to make it greater than the ablation threshold of 1.1 μJ on the surface of the processed sample film, and the laser energy can be continuously adjusted;

...

Embodiment 2

[0043] Preparation of crystalline Ge by eliminating linear polarization with multiple pulses 2 Sb 2 Te 5 The anisotropy of the composite nanostructure makes it present an isotropic geometric form as an example. Using the multi-pulse femtosecond laser processing polarization control method of the present invention, the femtosecond laser pulses used are circularly polarized. The specific processing steps are as follows:

[0044] Other steps are identical with embodiment 1, and difference is: before step (2) energy regulation is carried out, add quarter-wave plate 12 in optical path, adjust quarter-wave plate 12, make wave plate optical axis direction and The included angle of the original laser polarization direction is 45° to obtain circularly polarized femtosecond laser pulses.

[0045] In step (5), processing is performed under the condition of circularly polarized femtosecond laser pulses, and by changing the incident pulse energy, a uniformly arranged nanoparticle-single ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com