Graphene film, its preparation method and use

A graphene film and copper foil technology, applied in graphene, gaseous chemical plating, metal material coating process, etc., can solve the problems of low surface cleanliness and activity of copper foil, uneven growth of graphene film, etc. Uniform distribution of square resistance and transmittance, uniform and stable nucleation growth, and thorough removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

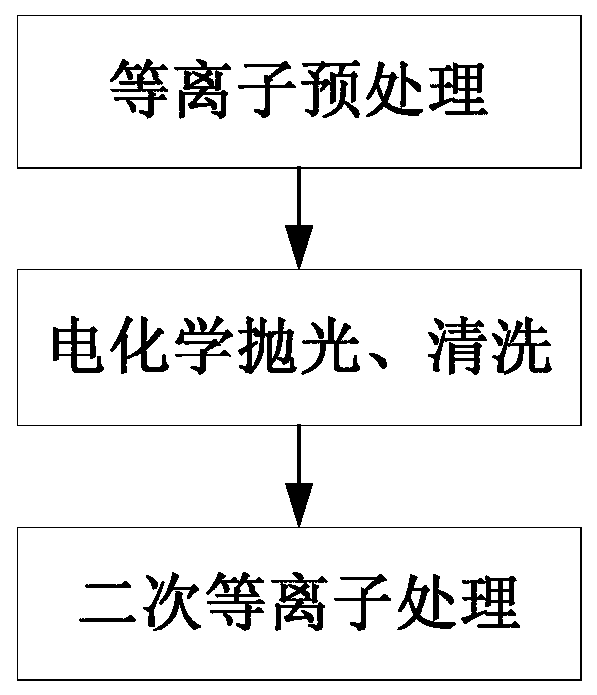

[0031] The preparation method of the graphene film of the present embodiment adopts the chemical vapor deposition (CVD) method, which includes: the copper foil blank is processed, and then the step of growing the graphene film on the copper foil substrate, see figure 1 , The steps of processing the copper foil include: (1) plasma pretreatment, (2) electrochemical polishing and cleaning, and (3) secondary plasma treatment. Specifically include the following steps:

[0032] (1) Plasma pretreatment: The treatment process is carried out in two steps. First, the cut copper foil blank is placed in a vacuum plasma cleaning machine, and a certain flow of oxygen is passed through to perform the first plasma decontamination treatment. The active particles in the oxygen plasma can go deep into the micro holes and depressions, completely remove the dirt on the surface of the copper foil blank through chemical reaction, and effectively improve the cleanliness of the surface of the copper f...

Embodiment 2

[0045] On the basis of the copper foil for graphene film growth in embodiment 1, the present invention also provides a kind of graphene film, this graphene film is made by the preparation method of above-mentioned graphene film, specifically through embodiment 1 described The graphene film is grown with copper foil.

[0046] See figure 2 As shown in Figure 6, the copper foil blanks that have undergone different processing processes are placed in the same diffusion furnace at the same time, and the growth process is controlled to carry out the nucleation and growth of CVD graphene film, and the obtained copper foil samples are placed on a constant temperature heating plate and baked at 150 °C After 5 minutes, observe with a metallographic microscope. The results are shown in Figure 6(a) to Figure 6(d). The white substance in the figure is the graphene film grains in the process of nucleation and growth. It can be seen from Figure 6(a) that the untreated copper foil has a larg...

Embodiment 3

[0048] A kind of transparent electrode on the basis of embodiment 2, it adopts described graphene film to make.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com