High-Cr-content high-pressure-resistance copper-chromium contact material and manufacturing method thereof

A technology of copper-chromium contacts and high pressure resistance, which is applied in the field of metal matrix composite materials, can solve the problems of insignificant improvement of the compressive strength of the chromium phase, difficulty in changing the composition and state of the chromium phase, and limited overall effect, and achieve good compactness , uniform structure, and the effect of improving the pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

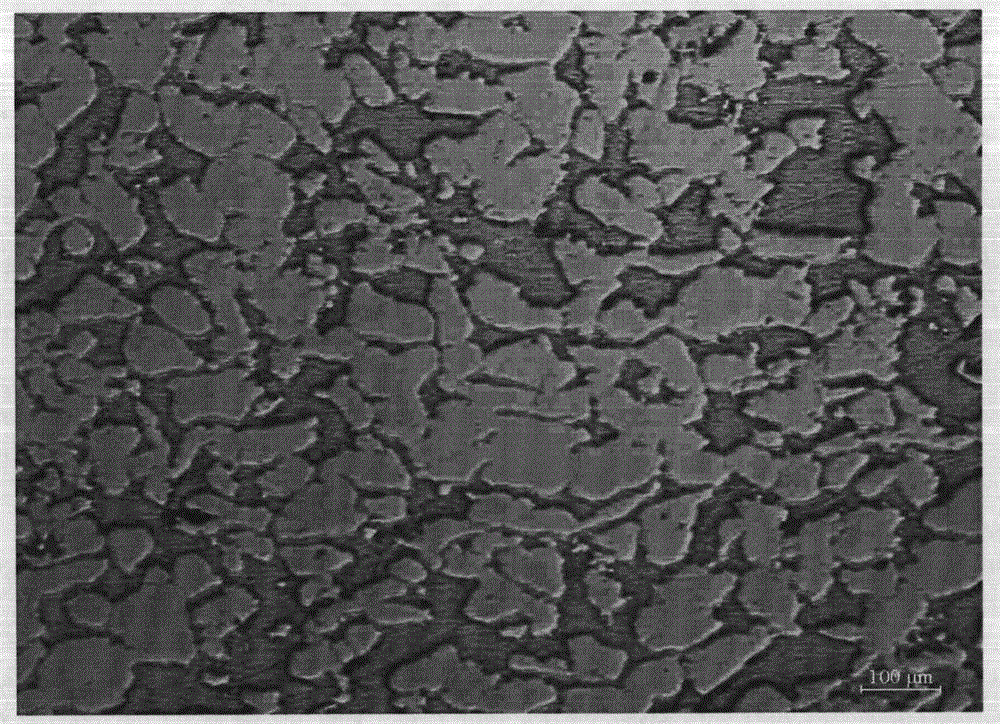

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

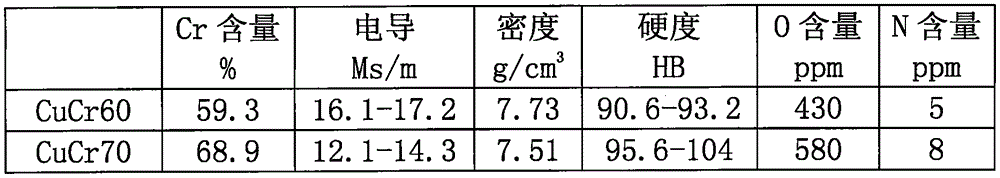

[0036] A copper-chromium contact material with high Cr content and high pressure resistance, which is composed of the following components in weight percentage: Cr is 60-70%, and the balance is Cu; the raw materials are respectively 50-100 micron Cr powder and 100 Cu powder below micron.

[0037] The chromium powder is electrolytic chromium powder or thermite reduced chromium powder, and the copper powder is electrolytic copper powder or atomized copper powder.

[0038] The purity of the chromium powder is 99.97%-99.98%.

[0039] The preparation method of the copper chromium contact material with high Cr content and high pressure resistance comprises the following steps:

[0040] (1) Raw material selection

[0041] Choose 50-100 micron chromium powder and 100 micron copper powder;

[0042] (2) mixed powder

[0043] Form the mixed powder of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com