Silicon dioxide aerogel, as well as continuous constant-pressure drying preparation method and system thereof

A silicon dioxide and atmospheric pressure drying technology, which is applied in the direction of silicon dioxide and silicon oxide, can solve the problems of cumbersome operation and achieve the effects of reduced preparation time, low energy consumption and easy continuous process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

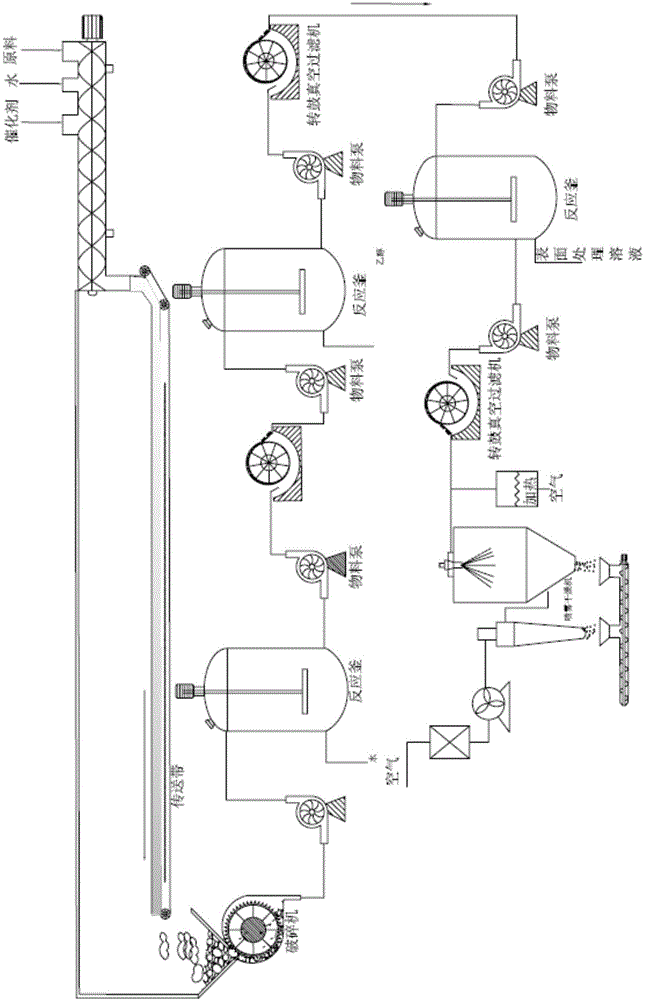

Image

Examples

preparation example Construction

[0038] Further, the preparation method includes: mixing the silicon source, water, catalyst and dryness control agent to homogenize the gel, then crushing the wet gel, and then replacing it with alcohol and liquid alkane, modifying it with a hydrophobic agent, and then separating Hydrophobic alkane gel is dried and sintered to obtain hydrophobic airgel powder.

[0039] In a preferred embodiment, the preparation method may include:

[0040] (1) Mix the silicon source, water, catalyst and drying control agent uniformly to form a mixed liquid;

[0041] (2) Transfer the mixed liquid obtained in step (1) to the conveyer belt, and form a gel during the conveying process, then input the gel into a crusher, and crush it to form granules or powder;

[0042] (3) input the gel particles or powder obtained in step (2) into the stirring tank, and input water at the same time, and heat and stir to obtain the gel-water slurry;

[0043] (4) The gel-water slurry obtained in step (3) is trans...

Embodiment 1

[0077] Example 1 see figure 1 , the method for preparing silica aerogel by continuous atmospheric pressure drying may comprise the steps:

[0078] 1) Water glass (silicon dioxide content 30wt%, modulus 2.3) was added to the continuous stirring system at a rate of 4 L / h, water at 16 L / h, and nitric acid at a rate of 0.5 L / h.

[0079] 2) After stirring, it enters the conveying system to form a gel, and the conveyor belt conveys the gel to the crusher, which becomes a gel powder after being crushed.

[0080] 3) The gel powder prepared in step (2) was pumped into the reactor at a rate of 20 L / h, and deionized water was pumped into the stirred reactor 1 at a rate of 80 L / h at the same time. The stirring speed of the reactor was 100 rpm, and the temperature of the reactor was 90°C.

[0081] 4) The water-hydrogel reaction product prepared in step (3) is pumped out at a rate of 100 L / h, and enters the drum vacuum filter 1, and is filtered and separated into hydrogel and water waste ...

Embodiment 2

[0088] (1) SiO 2 Preparation of gel particles: mix water glass (5% silicon content), water, and polyvinyl alcohol (2%), adjust the pH value between 4-6 with sulfuric acid, and let stand for 30 minutes to form a gel. The gel is mechanically stirred to obtain gel particles with a size between 0.01 mm and 0.5 mm.

[0089] (2) Solvent exchange: Gel particles and water (1:1, unless otherwise specified, the volume ratio below) are put into a stirring tank, the stirring speed is 100rpm to 500rpm, and the temperature is from room temperature to 90°C. After stirring for 5 hours, vacuum filtration was performed to obtain hydrogel particles. Put hydrogel particles and methanol or ethanol (1:1) into a stirred tank and stir, heat to 5°C below the boiling point of alcohol, stir for 1 hour, and vacuum filter to obtain alcohol gel. Alcohol gel particles and n-hexane (1:1) were put into a stirred tank and stirred, heated to 5°C below the boiling point of alcohol, stirred for 1 hour, and vacu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com