Corrosion-resistant low-temperature solder for photovoltaic solder strip and preparation method of corrosion-resistant low-temperature solder

A technology of low-temperature solder and photovoltaic ribbon, applied in welding equipment, welding/cutting medium/material, welding medium, etc., can solve problems such as corrosion resistance of materials that are not involved, achieve strong corrosion resistance, avoid segregation phenomenon, melting point low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

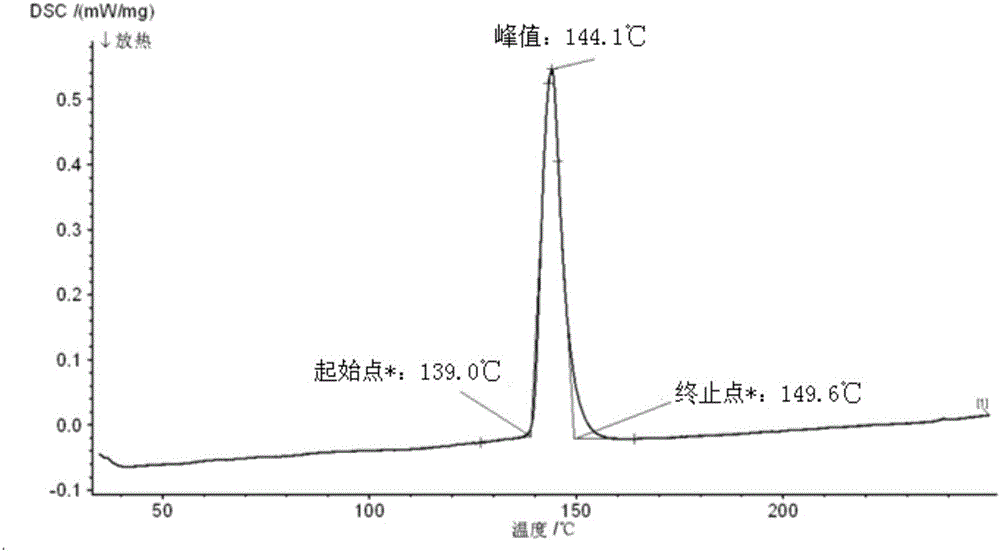

Embodiment 1

[0039] When smelting, first mix and heat an appropriate amount of pure tin (99.95%) and pure bismuth (99.95%) to 300°C for the mixed melt, then add bismuth chloride powder to cover the surface of the mixed melt (the ratio of the mass of the mixed melt to the mass of bismuth chloride 20:1) after heat preservation and stirring for 15 minutes, the temperature was lowered to 170°C to obtain molten solder, and then the molten solder was poured into a graphite crucible covered with a porous carbon filter layer (thickness: 2 mm), and the melt in the graphite crucible was repeatedly Filter 3 times. Reduce the temperature of the filtered molten solder to 150°C, inject carbon monoxide from the bottom of the solder and keep it for 30 minutes, and finally remove the slag floating on the surface of the melt and cast it to obtain the finished product. After spark direct reading spectroscopy and chemical analysis (see: National Standard GB / T 10574.1-13 "Chemical Analysis Method for Tin-Lead ...

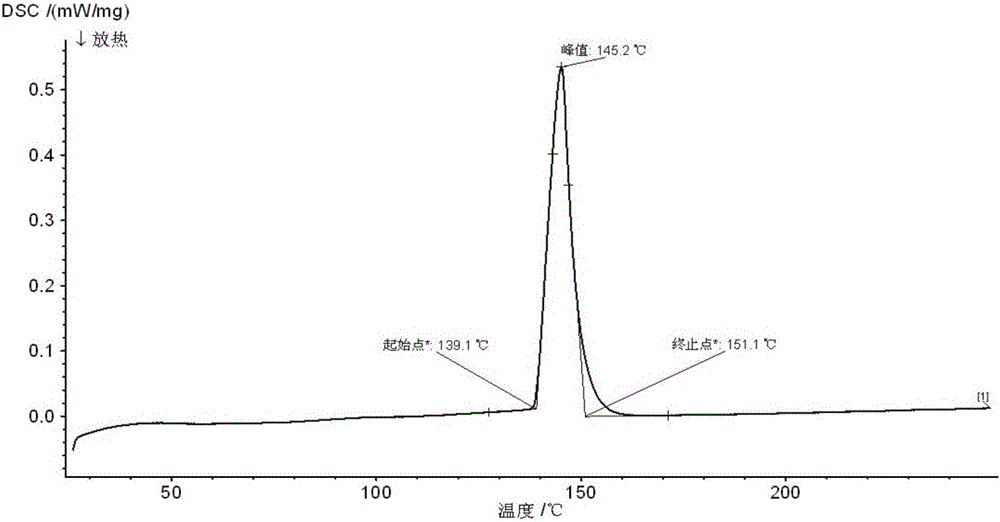

Embodiment 2

[0043] When smelting, first mix and heat appropriate amount of pure tin (99.95%) and pure bismuth (99.95%) to 280°C to mix the melt, then add bismuth chloride powder to cover the surface of the melt (mass ratio of mixed melt to bismuth chloride is 20:1) After heat preservation and stirring for 20 minutes, the temperature was lowered to 170°C to melt the solder, and then the molten solder was poured into a graphite crucible covered with a porous carbon filter layer (2 mm in thickness), and the melt in the graphite crucible was repeatedly filtered for 5 Second-rate. Reduce the temperature of the filtered molten solder to 150°C, inject carbon monoxide from the bottom of the solder and keep it for 30 minutes, and finally remove the slag floating on the surface of the melt and cast it to obtain the finished product. According to spark direct reading spectroscopy and chemical analysis, the bismuth content of the solder prepared by this process is 59% by mass, and the rest are impuri...

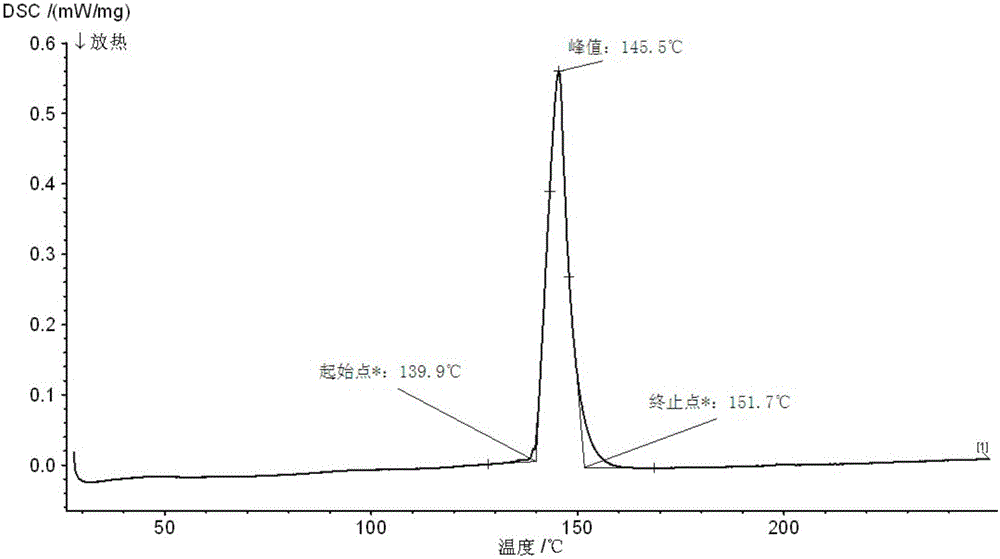

Embodiment 3

[0046]When smelting, first mix and heat appropriate amount of pure tin (99.95%) and pure bismuth (99.95%) to 280°C to mix the melt, then add bismuth chloride powder to cover the surface of the mixed melt (the mass of the mixed melt and the mass of bismuth chloride The ratio is 20:1) after heat preservation and stirring for 18 minutes, the temperature is lowered to 175°C to obtain molten solder, and then the molten solder is poured into a graphite crucible covered with a porous carbon filter layer (thickness is 2 mm), and the melt in the graphite crucible Filter repeatedly 8 times. Reduce the temperature of the filtered molten solder to 150°C, inject carbon monoxide from the bottom of the solder and keep it for 40 minutes, and finally remove the slag floating on the surface of the melt and cast it to obtain the finished product. According to spark direct reading spectroscopy and chemical analysis, the bismuth content of the solder prepared by this process is 60% by mass, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com