Heparan polyethersulfone hollow fiber membrane and preparation method and applications thereof

A technology of heparinization and polyethersulfone is applied in the field of heparin-like polyethersulfone hollow fiber membrane and its preparation, which can solve the problem of membrane structure, poor performance stability, reduced membrane strength and mechanical properties, and reduced membrane filtration stability. It can achieve the effect of stable anticoagulation ability, uniform structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

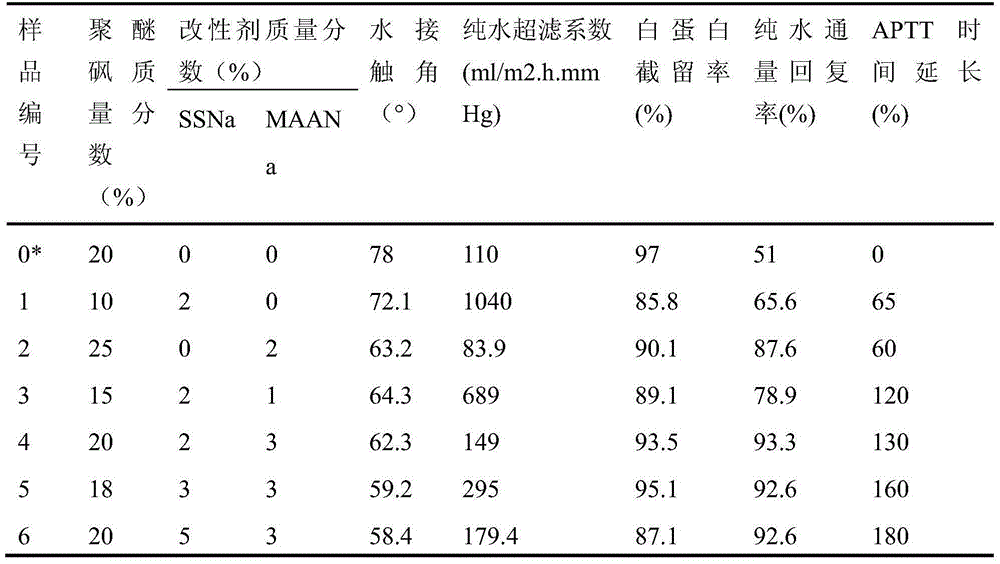

Examples

Embodiment 1

[0027] Put 10 parts of polyethersulfone and 90 parts of N,N-dimethylacetamide into a reaction kettle equipped with a stirrer, thermometer and heater, and dissolve completely at a temperature of about 70°C under stirring. 2 parts of SSNa were added, the amount of N,N'-methylenebisacrylamide was 1% of the mole fraction of the reaction monomers, and the amount of azobisisobutyronitrile was 1% of the mole fraction of the reaction monomers. After gradually adding under stirring, react at a temperature of about 80°C for about 12 hours to obtain a modified polyethersulfone solution. After filtering and defoaming, it is left to "cure" to obtain a polyethersulfone spinning raw solution.

[0028] Press-filter the polyethersulfone spinning solution, and extrude it through two concentric hollow fiber spinnerets with a metering pump. The extrusion speed of the spinning solution is 7ml / min; Solidify and form in a water bath at 35°C; then stretch and wind in a plasticizing bath at a speed o...

Embodiment 2

[0030] Put 25 parts of polyethersulfone and 75 parts of N,N-dimethylacetamide into a reaction kettle equipped with a stirrer, thermometer and heater, and dissolve completely at a temperature of about 80°C under stirring. 2 parts of MAANa were added, the amount of N, N'-methylenebisacrylamide was 1% of the mole fraction of the reaction monomers, and the amount of azobisisobutyronitrile was 1% of the mole fraction of the reaction monomers. After gradually adding under stirring, react at a temperature of about 90°C for about 12 hours to obtain a modified polyethersulfone solution. After filtering and defoaming, place it for "aging" to obtain a polyethersulfone spinning solution.

[0031] Press-filter the polyethersulfone spinning solution, and extrude it through two concentric hollow fiber spinnerets with a metering pump. The extrusion speed of the spinning solution is 7ml / min; Solidify and form in a water bath at 30°C; then stretch and wind in a plasticizing bath at a speed of ...

Embodiment 3

[0033] Put 15 parts of polyethersulfone and 85 parts of N,N-dimethylformamide into a reaction kettle equipped with a stirrer, thermometer and heater, and dissolve completely at a temperature of about 70°C under stirring. 2 parts of SSNa and 1 part of MAANa were added, the amount of N,N'-methylenebisacrylamide added was 1% of the mole fraction of the reaction monomers, and the amount of dibenzoyl peroxide added was 1% of the mole fraction of the reaction monomers. After gradually adding under stirring, react at a temperature of about 80°C for about 12 hours to obtain a modified polyethersulfone solution. After filtering and defoaming, place it for "aging" to obtain a polyethersulfone spinning solution.

[0034] Press-filter the polyethersulfone spinning solution, and extrude it through two concentric hollow fiber spinnerets with a metering pump. The extrusion speed of the spinning solution is 7ml / min; Solidify and form in a water bath at 35°C; then stretch and wind in a plasti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com