Gradient cemented carbide with surface softening and preparation method thereof

A cemented carbide and gradient technology, which is applied in the field of surface softened gradient cemented carbide and its preparation, can solve problems such as the failure of cemented carbide coated tools, and achieve excellent mechanical properties, growth inhibition, and fine WC grains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-35

[0028] Embodiments 1-35 provide a surface-softened gradient cemented carbide and a preparation method of the surface-softened gradient cemented carbide.

[0029] The mass percentage of each component of the alloy binder phase used in Examples 1-35 is shown in Table 1 below, and the mass percentage of each component used to prepare the surface-softened gradient cemented carbide is shown in Table 2 below.

[0030] Table 1 The components of the alloy binder phase in Examples 1-35

[0031]

[0032] Table 2 Components used to prepare surface-softened gradient cemented carbide in Examples 1-35

[0033]

[0034]

[0035] The preparation method of the surface-softened gradient cemented carbide of embodiment 1-35 comprises the following steps:

[0036] (1) Preparation of alloy binder phase

[0037] Weigh the metal powders that make up the alloy binder phase according to the mass percentage, put the metal powders in an omnidirectional planetary ball mill, and use cemented car...

Embodiment 36

[0048] This embodiment provides a surface-softened gradient cemented carbide and a preparation method of the surface-softened gradient cemented carbide.

[0049] The composition of the alloy binder phase, raw material powder and paraffin wax in this example is consistent with that of Example 10.

[0050] In the preparation method of this embodiment, the preparation of the alloy binder phase, the preparation of the blank, the pressing of the blank, and the pre-sintering are consistent with those of Example 10. The difference between this example and Example 10 lies in the sintering step, which is as follows:

[0051] Put the green body in the sintering furnace, raise the temperature to 1200-1250°C at a speed of 5-8°C / min, then raise the temperature to 1420-1450°C at a speed of 1-3°C / min, then keep it warm for 80min, and keep it for 10 -3 Vacuum degree above Pa. Then cool down to 1000-1200°C at a rate of 2-6°C / min, keep warm for 120min, and keep for 10 -3 The degree of vacuum ...

Embodiment 10

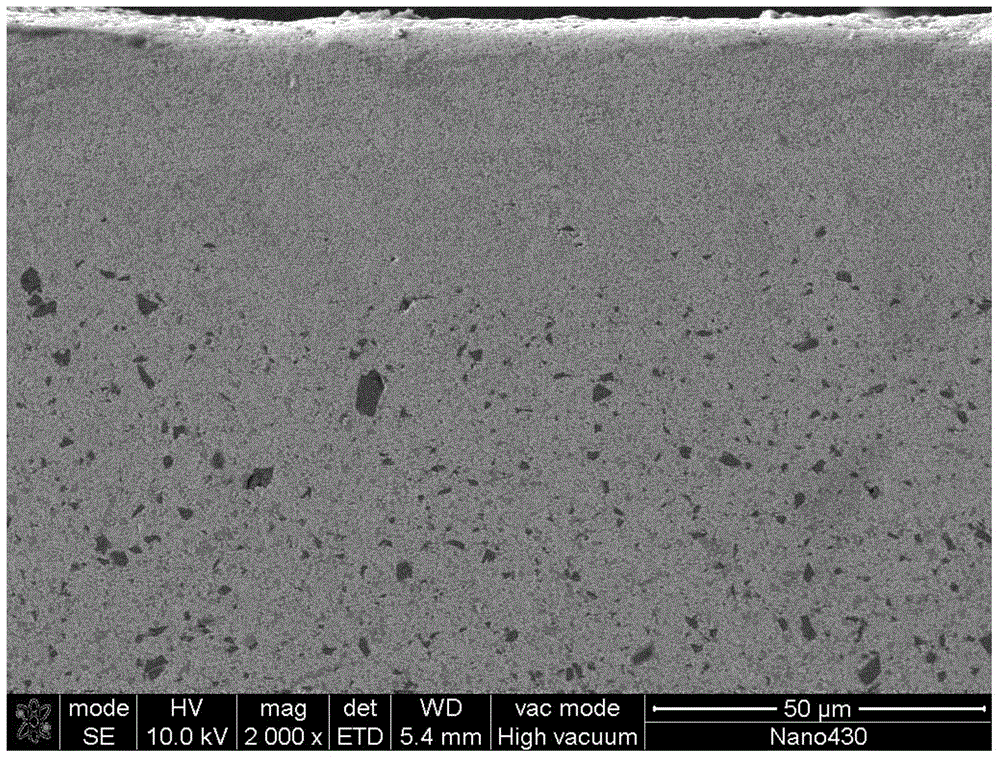

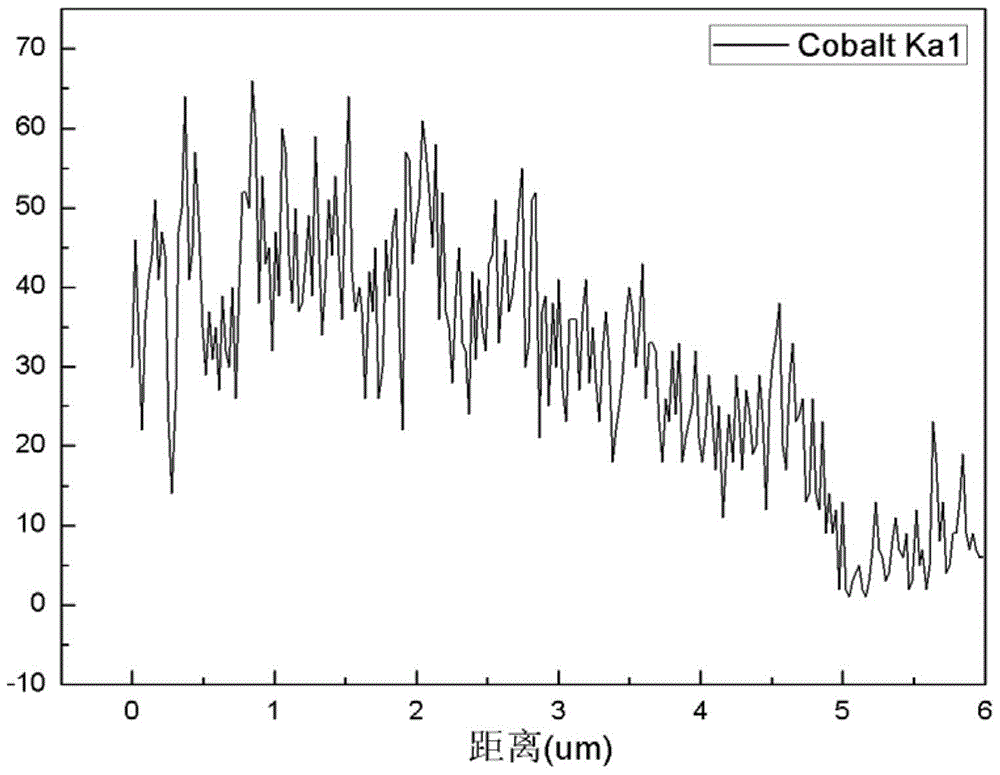

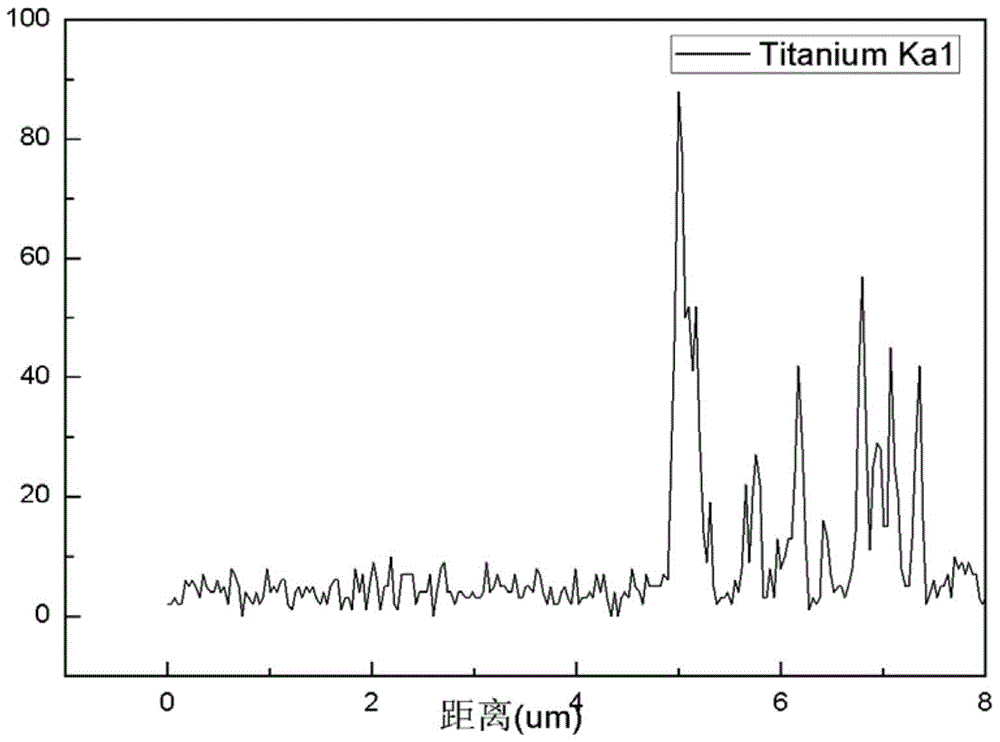

[0057] The cross-sectional micro-morphology of the surface-softened gradient cemented carbide HJ10 prepared in Example 10 is as follows figure 1 As shown, it can be seen from the figure that there is basically no Ti-containing cubic phase on the surface of the alloy (substantially no black spots on the surface); figure 2 It is a line scan diagram of the Co content of the section of HJ10 (the "distance" on the abscissa refers to the vertical distance from the outer surface of the object to the scanning point), and within a certain thickness range, the Co content shows a decreasing trend from the surface to the inside; image 3 It is a line scan diagram of the Ti content of the section of HJ10 (the "distance" on the abscissa refers to the vertical distance from the outer surface of the object to the scanning point), and within a certain thickness range, the Ti content shows an increasing trend from the surface to the inside; Figure 4 It is the XRD spectrum of HJ10, the alloy s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com