The preparation method of fe-cr-co type alloy strip magnet

A kind of fe-cr-co, 1.fe-cr-co technology, applied in the direction of inductance/transformer/magnet manufacturing, furnace type, manufacturing tools, etc., can solve the problem of high cost, difficult production of millimeter-level thickness sheets, hard magnetic low ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The first step, raw material preparation:

[0049] According to the mass percentage of 62Fe-25Cr-12Co-1Ti, the component raw materials of pure Fe, Co, Ti and Cr-Fe alloy containing 62wt% Cr-38wt% Fe are weighed to complete the raw material preparation, and the purity of all component raw materials is mass Percentage≥99.9%;

[0050] The second step is to prepare Fe-Cr-Co type master alloy ingot:

[0051] Put all the raw materials prepared in the first step into the crucible of the vacuum arc melting furnace. When melting, first vacuumize the furnace body to 5×10 -2 Below Pa, the furnace temperature rises above the highest melting point of the raw material metal until all the raw material metal is completely melted to obtain a uniformly smelted 62Fe-25Cr-12Co-1Ti melt, and then the melt is cooled in a water-cooled copper crucible to obtain Fe -Cr-Co type master alloy ingot, that is, 62Fe-25Cr-12Co-1Ti master alloy ingot;

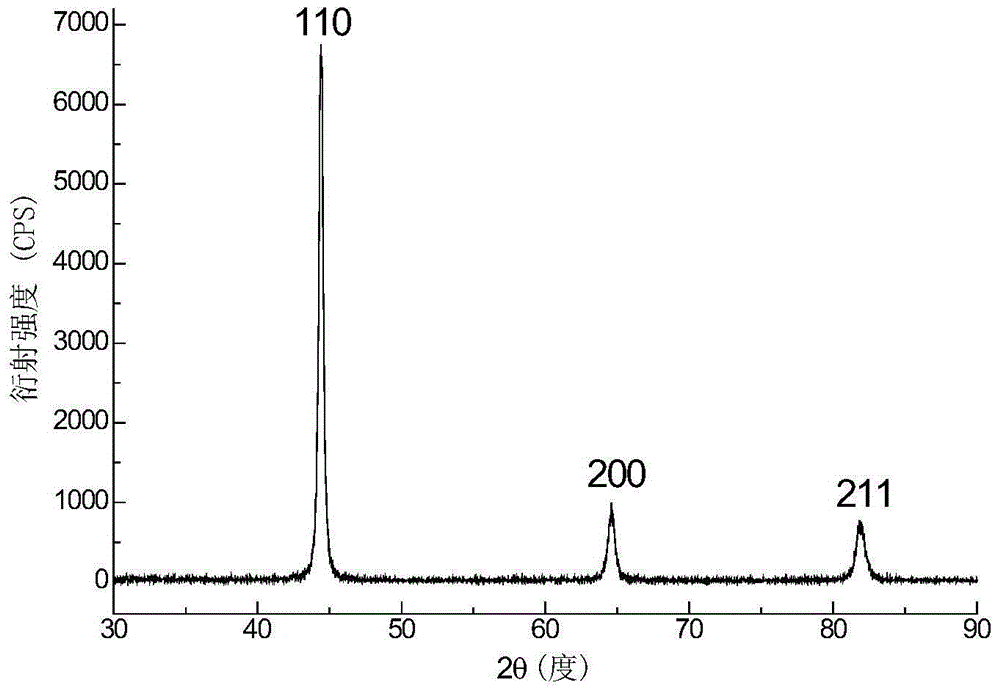

[0052] figure 1 The examples shown show that ...

Embodiment 2

[0061] The first step, raw material preparation:

[0062] According to the mass percentage of 62.5Fe-24Cr-12Co-1.5Si, the component raw materials pure Fe, Co, Si and the Cr-Fe alloy containing 62wt%Cr-38wt%Fe are weighed to complete the preparation of raw materials, and the purity of all component raw materials is uniform. For the mass percentage ≥ 99.9%;;

[0063] The second step is to prepare Fe-Cr-Co type master alloy ingot:

[0064] Put all the raw materials prepared in the first step into the crucible of the vacuum induction melting furnace, and evacuate the furnace body to 5×10 -2 Below Pa, the furnace temperature rises to be higher than the highest melting point of the raw material metal until all the raw material metal is completely melted to obtain a uniformly smelted 62.5Fe-24Cr-12Co-1.5Si melt, and then the melt is cooled in a water-cooled copper crucible to produce Obtain Fe-Cr-Co type master alloy ingot, that is, 62.5Fe-24Cr-12Co-1.5Si master alloy ingot;

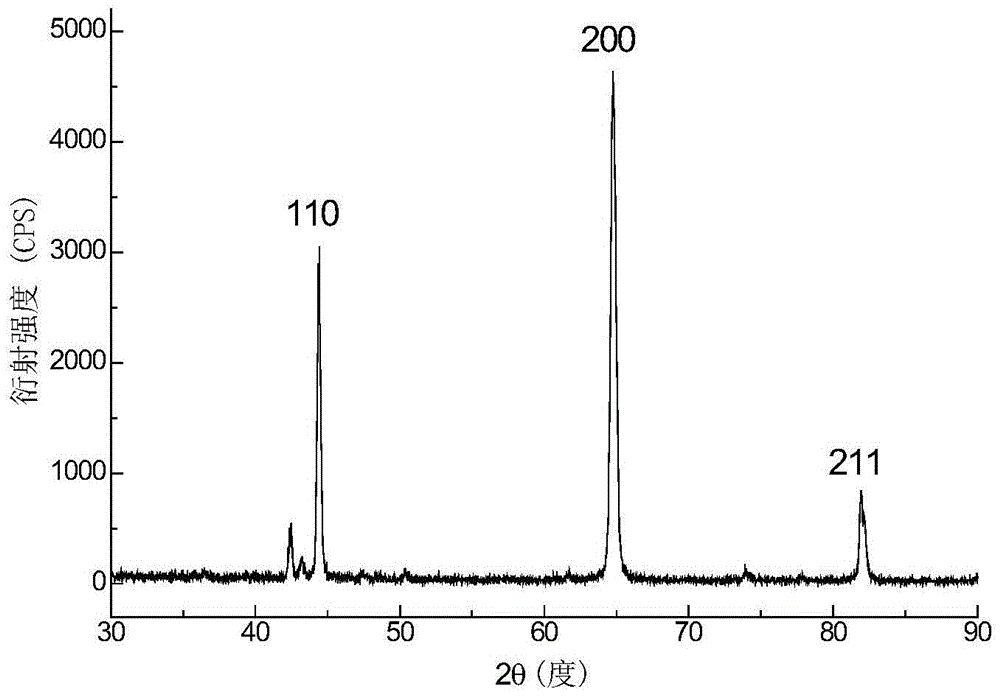

[00...

Embodiment 3

[0074] The first step, raw material preparation:

[0075] According to the mass percentage 62Fe-24Cr-12Co-1Si-1Ti, weigh the component raw materials pure Fe, Co, Si, Ti and Cr-Fe alloy containing 62wt% Cr-38wt% Fe, thus completing the raw material preparation, all component raw materials Purity is mass percentage ≥ 99.9%;

[0076] The second step is to prepare Fe-Cr-Co type master alloy ingot:

[0077] Put all the raw materials prepared in the first step into the crucible of the vacuum arc melting furnace. When melting, first vacuumize the furnace body to 5×10 -2 Below Pa, the furnace temperature rises to be higher than the highest melting point of the raw material metal until all the raw material metal is completely melted to obtain a smelted uniform 62Fe-24Cr-12Co-1Si-1Ti melt, and then the melt is cooled in a water-cooled copper crucible to produce Obtain Fe-Cr-Co type master alloy ingot, that is, 62Fe-24Cr-12Co-1Si-1Ti master alloy ingot;

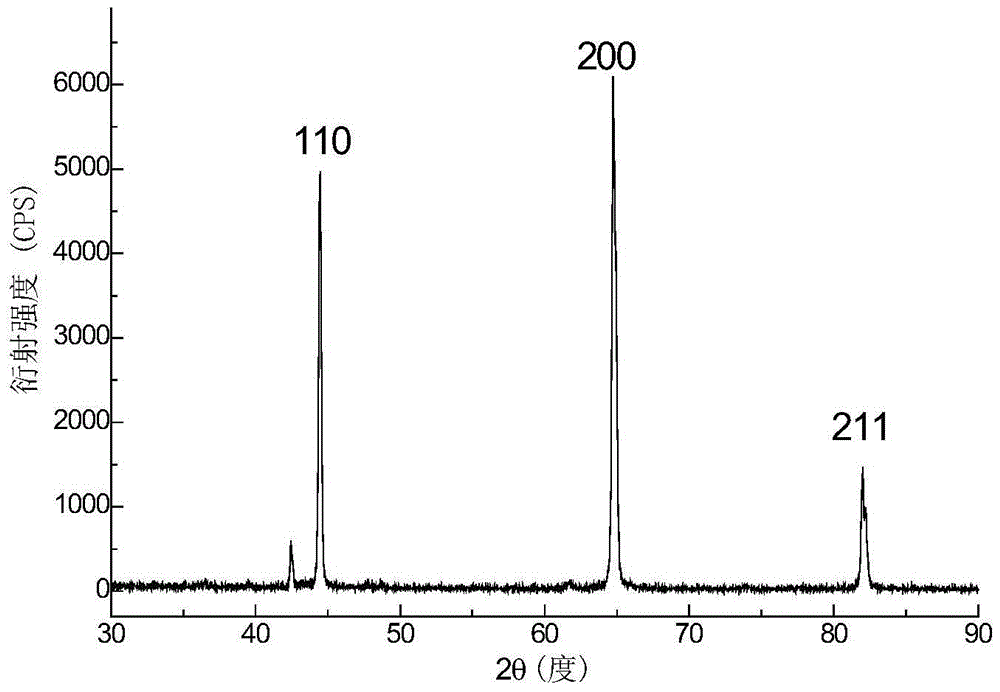

[0078] Figure 11 The exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com