Solvent-free anticorrosive coating

An anti-corrosion coating, solvent-free technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of short validity period of the coating, low coating adhesion, high cost, etc., to achieve good curing effect, Solve the effect of high cost and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A solvent-free anti-corrosion coating, which consists of component A accounting for 68% of the total weight of the coating, component B accounting for 18% of the total weight of the coating, and component C accounting for 14% of the total weight of the coating, wherein:

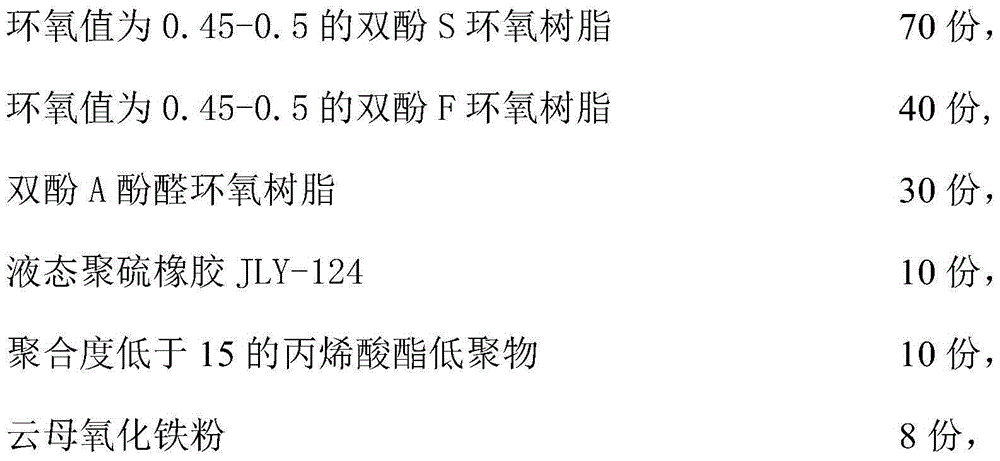

[0023] A component is composed as follows by weight part:

[0024]

[0025]

[0026] B component is composed as follows by weight part:

[0027] Shell epoxy company H-6 curing agent 10 parts,

[0028] Air Products Company K-54 Accelerator 7 parts,

[0029] C component is composed as follows by weight:

[0030] Resolution company CY-F206 curing agent 10 parts,

Embodiment 2

[0033] A solvent-free anti-corrosion coating, consisting of component A accounting for 72% of the total weight of the coating, component B accounting for 16% of the total weight of the coating, and component C accounting for 12% of the total weight of the coating, wherein:

[0034] A component is composed as follows by weight part:

[0035]

[0036]

[0037] B component is composed as follows by weight part:

[0038] Shell epoxy company H-6 curing agent 10 parts,

[0039] Air Products company K-54 Accelerator 6 parts,

[0040] C component is composed as follows by weight:

[0041] Resolution company CY-F206 curing agent 10 parts,

Embodiment 3

[0044] A solvent-free anti-corrosion coating, which consists of component A accounting for 64% of the total weight of the coating, component B accounting for 20% of the total weight of the coating, and component C accounting for 16% of the total weight of the coating, wherein:

[0045] A component is composed as follows by weight part:

[0046]

[0047]

[0048] B component is composed as follows by weight part:

[0049] Shell epoxy company H-6 curing agent 10 parts,

[0050] Air Products Company K-54 Accelerator 7 parts,

[0051] C component is composed as follows by weight:

[0052] Resolution company CY-F206 curing agent 10 parts,

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com