Precious metal-silicon composite powder prepared through galvanic reaction and application thereof

A technology of composite powder and metal silicon powder, which is applied in the direction of metal/alloy conductors, etc., can solve the problems of increasing the preparation cost of silver-coated composite materials, limited reducing agents, high process requirements, etc., and achieves easy industrial production, easy operation, and preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

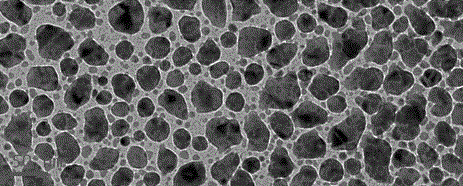

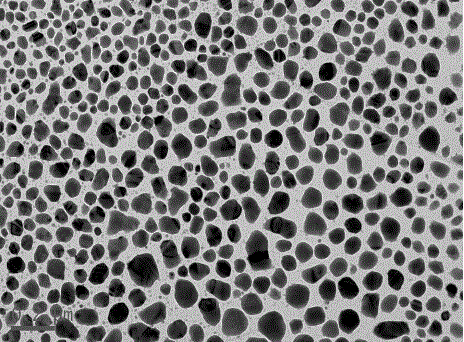

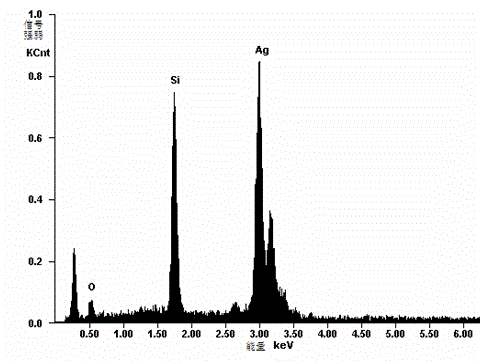

Image

Examples

Embodiment 1

[0044] The silver-silicon composite powder prepared by the galvanic reaction of this embodiment is made by the following method:

[0045] (1) Prepare a hydrofluoric acid solution with a concentration of 5mol / L, and stir the hydrofluoric acid solution;

[0046] (2) Add the hydrofluoric acid solution prepared in step (1) into a container containing 0.7mol ultrafine silicon powder, and continue to stir to remove the oxide layer on the surface of the ultrafine silicon powder; since the surface of the silicon powder is oxidized , so the surface SiO 2 It will be corroded by hydrofluoric acid, and a large number of irritating bubbles will be generated in the solution. The specific reaction is as follows: SiO 2 +6HF→H 2 SiF 6 +2H 2 O;

[0047] After the EDX element test, the oxygen content of the ultrafine silicon micropowder is 16%, corresponding to the SiO2 content of 30%, which is corroded by hydrofluoric acid, so only 70% of the silicon remains to participate in the subsequen...

Embodiment 2

[0058] The difference between this example and Example 1 is that in step (1), a hydrofluoric acid solution with a concentration of 1 mol / L is prepared; The silicon waste produced during sawing, edging, polishing, and multi-wire cutting machine processing, the average particle size of the silicon waste is 5 microns; in step (3), configure 2L of a solution containing 0.001mol / L silver nitrate; silver nitrate solution Silver oxide was reacted with nitric acid and dissolved in water; in step (4), the galvanic reaction time was 60 minutes; in step (5), the powder was separated by filtration, elemental analysis of silver-silicon composite powder, silver in silver-silicon composite powder : Silicon ≈ 3:7, silver accounts for 30% of the composite powder, and silicon accounts for 70%.

[0059] All the other are with embodiment 1.

[0060] Application: Apply the above silver-silicon composite powder to conductive ink for printed electronics. According to the conventional process of co...

Embodiment 3

[0062] The method for preparing gold-silicon composite powder by galvanic reaction in this embodiment, and the application of the gold-silicon composite powder prepared by this process, includes the following steps:

[0063] (1) Prepare a hydrofluoric acid solution with a concentration of 3mol / L, and stir the hydrofluoric acid solution;

[0064] (2) Slowly add the hydrofluoric acid solution prepared in step (1) into a container containing 40 grams of ultrafine silica powder, and continue stirring to remove the oxide layer on the surface of the ultrafine silica powder; oxidized, so the surface SiO 2 It will be corroded by hydrofluoric acid, and a large number of irritating bubbles will be generated in the solution. The specific reaction is as follows: SiO 2 +6HF→H 2 SiF 6 +2H 2 O;

[0065] (3) Prepare a solution containing about 24 grams of chloroauric acid, the gold content is about 14 grams, which is 0.071 mol;

[0066] (4) Gradually add the chloroauric acid solution in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com