TiCN/Al2O3 metal ceramic cutter and microwave preparation process thereof

A cermet and preparation technology, applied in the field of microwave sintering material science, can solve the problems of materials affecting mechanical properties, reducing material fracture toughness, etc., and achieve the effects of simple process equipment, improved fracture toughness, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

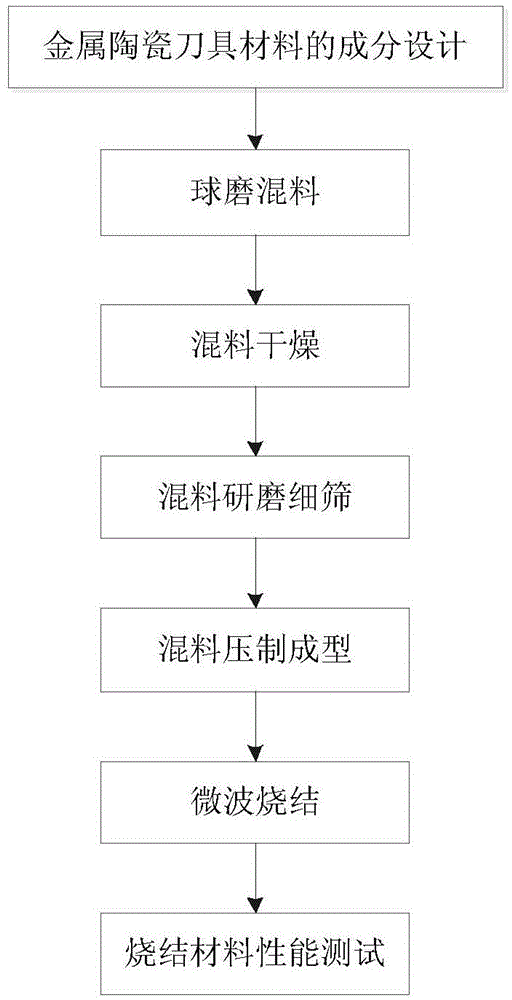

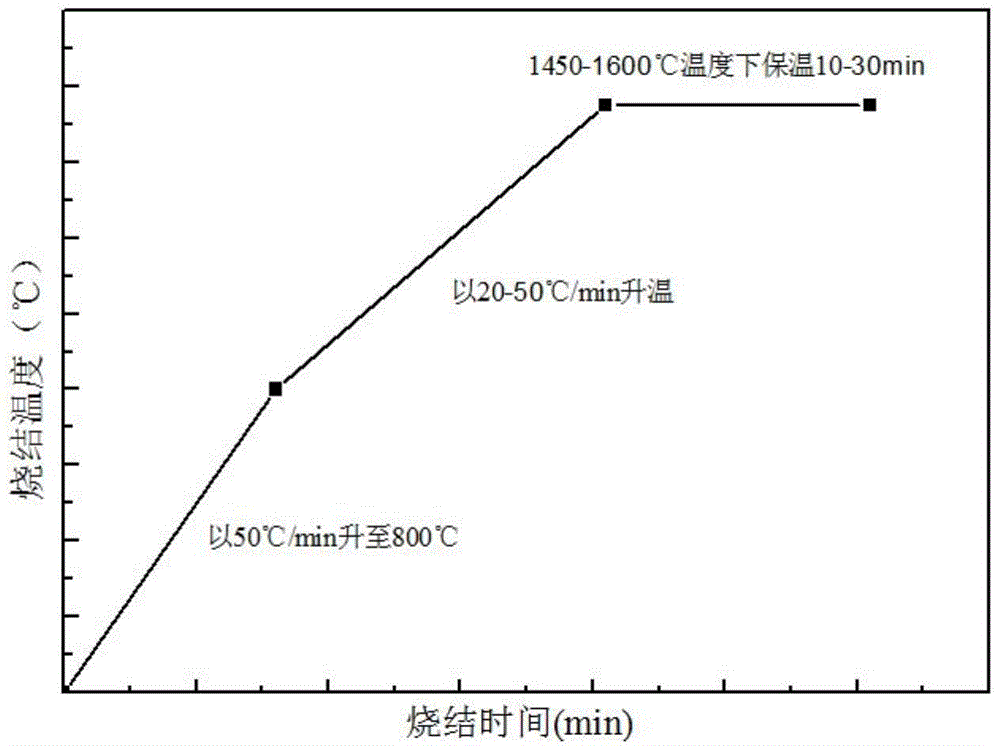

[0024] combine figure 1 , a TiCN / Al of the present invention 2 o 3 Microwave preparation of cermet tool materials by mass percentage TiCN 40%, α-Al 2 o 3 15%, Mo 2 C 10%, WC 10%, Co and Ni 25% ingredients are mixed by ball milling, and a polyvinyl alcohol solution with a concentration of 1% is prepared, and added to the mixed powder 2 hours before the end of ball milling, and the powder after ball milling is dried With a 70-mesh sieve, dry-press the sieved powder to form a pressure of 200 MPa, and hold the pressure for 1 minute; place the formed sample in a microwave sintering furnace, turn on the vacuum pump, and put it into the furnace after the furnace is pumped to a vacuum state. Fill with nitrogen gas of 60KPa, then turn on the microwave power supply for heating, combined with figure 2 , heat the sample to 650°C at a speed of 50°C / min, heat to 1550°C at a heating rate of 20°C / min, keep at this temperature for 30 minutes, and then cool to room temperature with the fu...

Embodiment 2

[0026] combine figure 1 , a TiCN / Al of the present invention 2 o 3 Microwave preparation of cermet tool materials by mass percentage TiCN 45%, α-Al 2 o 3 15%, Mo 2 C 10%, WC 10%, Co and Ni 20% ingredients are mixed by ball milling, and a polyvinyl alcohol solution with a concentration of 5% is prepared, and added to the mixed powder 2 hours before the end of ball milling, and the powder after ball milling is dried 100-mesh sieve, dry-press the sieved powder, the pressure is 300MPa, and the holding time is 2min; put the formed sample in the microwave sintering furnace, turn on the vacuum pump, and after the furnace body is pumped to a vacuum state, put it into the furnace Fill with 40KPa nitrogen, then turn on the microwave power supply for heating, combined with figure 2 , heat the sample to 800°C at a speed of 80°C / min, heat to 1600°C at a heating rate of 50°C / min, keep at this temperature for 10 minutes, and then cool to room temperature with the furnace. After testin...

Embodiment 3

[0028] combine figure 1 , a TiCN / Al of the present invention 2 o 3Microwave preparation of cermet tool materials by mass percentage TiCN 50%, α-Al 2 o 3 12%, Mo 2 C 15%, WC 5%, Co and Ni 18% ingredients are mixed by ball milling, and a polyvinyl alcohol solution with a concentration of 7% is prepared, and added to the mixed powder 2 hours before the end of ball milling, and the powder after ball milling is dried 200-mesh sieve, dry-press the sieved powder to form, the pressure is 350MPa, and the holding time is 3min; put the formed sample in the microwave sintering furnace, turn on the vacuum pump, and after the furnace body is pumped to a vacuum state, put it into the furnace Fill with nitrogen gas of 60KPa, then turn on the microwave power supply for heating, combined with figure 2 , heat the sample to 800°C at a speed of 60°C / min, heat to 1550°C at a heating rate of 30°C / min, keep at this temperature for 20 minutes, and then cool to room temperature with the furnace. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com