Method for preparing monoisopropanolamine by virtue of reactive rectification

A technology of isopropanolamine and reactive distillation, applied in chemical instruments and methods, preparation of organic compounds, sustainable manufacturing/processing, etc., can solve the problem of high molar ratio of ammonia ring to feed ratio and high ratio of triisopropanolamine , a large number of equipment and other problems, to achieve the effect of reducing side reactions, reducing energy consumption, saving equipment costs and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

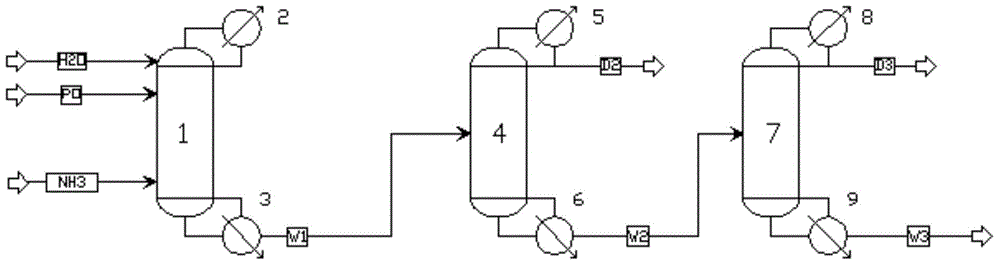

[0029]Reactive distillation tower 1 is a sieve tray tower with 25 actual plates, and its operating pressure is 1.2MPa, which is used to ensure that the press is in a liquid phase state and an effective reaction phase state. mining. The temperature at the top of the tower is controlled at about 35°C, and the temperature at the bottom of the tower is 204-205°C. Water at 25°C enters from the first block of the reactive distillation column 1, and the feed flow rate is 400kg / h. Propylene oxide at 25°C enters from the second plate with a feed flow rate of 1160kg / h. Liquid ammonia enters from the 24th plate of the reactive distillation column 1; the feed flow rate is 340kg / h. The molar ratio of liquid ammonia to propylene oxide is 1:1; the condenser 2 in the tower is a total condenser, and the reboiler 3 in the tower is a kettle-type reboiler, and its heat load is 7863kw. The tower top consists of unreacted ammonia and a small amount of water and propylene oxide, and the bottom st...

Embodiment 2

[0033] Reactive distillation tower 1 is a stainless steel θ-ring packed tower with an equal plate height of 40 blocks. The operating pressure is 1.1 MPa, which is used to ensure that the press is in a liquid phase state and an effective reaction phase state. The top of the tower is fully refluxed and the temperature of the tower is controlled. At about 31°C, the temperature of the tower kettle is about 165°C. Water at 25° C. enters from the top of the reactive distillation column 1, and the feed flow rate is 400 kg / h. Propylene oxide at 25°C enters from a position slightly lower than the water feed, and the feed flow rate is 1160kg / h. Liquid ammonia enters from the bottom of the reactive distillation column 1, and the feed flow rate is 510kg / h. The feed molar ratio of ammonia to propylene oxide was 1.5:1. The condenser 2 in the tower is a total condenser, and the reboiler 3 in the tower is a kettle-type reboiler, and its heat load is 7391kw. The top composition includes unr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com