A kind of preparation method of high-strength zirconia ceramic ferrule

A zirconia ceramic, high-strength technology, applied in the coupling of optical waveguides, etc., can solve the problems of uneven optical fiber penetration into the inner hole, increased insertion loss of optical fibers, and coarse and large grains, and achieve excellent thermal shock resistance. Performance, fast degreasing, high toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The embodiment of the present invention discloses a method for preparing a high-strength zirconia ceramic ferrule, which includes the following steps:

[0037] Step a) mixing nano titanium dioxide, aluminum oxide, scandium oxide, cerium oxide and zirconium oxide, adding paraffin wax after pre-calcination, mixing by ball milling, and obtaining partially stabilized zirconium oxide powder after sieving;

[0038] Step b) Add the partially stabilized zirconia powder and polystyrene into the internal mixer, add polyethylene glycol and microcrystalline wax after mixing, add ethylene-vinyl acetate copolymer, zinc stearate, SEBS elastic Body (polystyrene-polyethylene-polybutylene-polystyrene) and polyaldehyde resin, stir, heat up to 140-150°C, then add adipic acid dioctanoic acid, heat up to 160-180°C after stirring, banbury After cooling, a gelatinous substance is obtained;

[0039] Step c) compressing the gelatinous substance into tablets, pulverizing it, and obtaining a blan...

Embodiment 1

[0081] Step 1. Mix 1 part by weight of nano-titanium dioxide, 2 parts by weight of alumina, 1 part by weight of scandium oxide, 2 parts by weight of cerium oxide and 94 parts by weight of zirconia, and then pre-sinter at 700 ° C After 2 hours, 3 parts by weight of paraffin was added for ball milling, mixing and sieving to obtain a partially stabilized zirconia powder substrate.

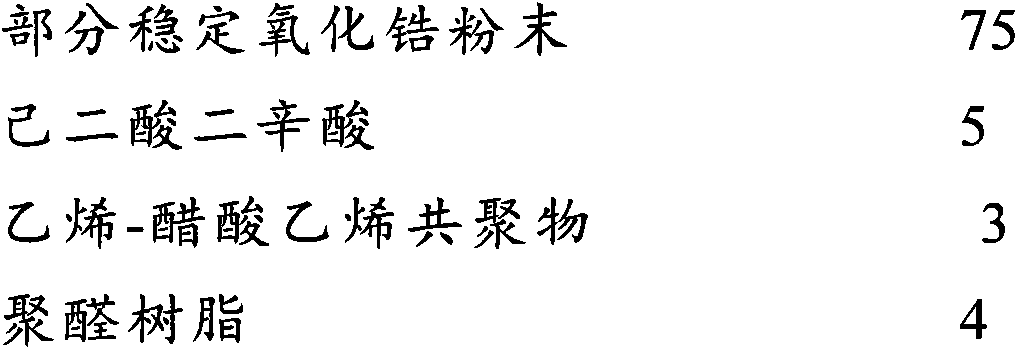

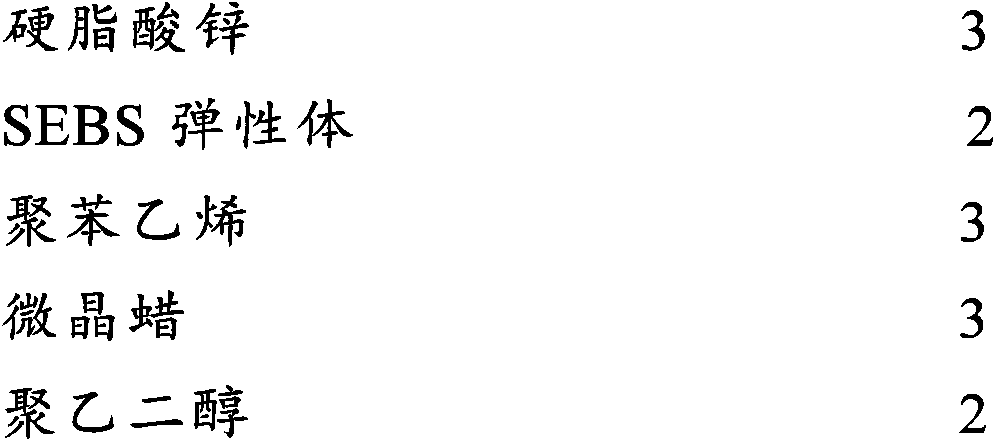

[0082] Step 2. Mix the partially stabilized zirconia powder substrate prepared above with organic carriers such as binders, surface active agents, and plasticizers in a certain proportion. The raw materials used in this step include in parts by weight:

[0083]

[0084]

[0085] Raise the temperature of the internal mixer to 120°C, then add the above-mentioned parts by weight of partially stabilized zirconia powder into the above-mentioned internal mixer, mix and stir for 10 minutes, so that polystyrene is evenly included on the powder particles, and then add the corresponding parts by weight of ...

Embodiment 2

[0108] Step 1. Mix 1 part by weight of nano titanium dioxide, 2 parts by weight of alumina, 1 part by weight of scandium oxide, 2 parts by weight of cerium oxide and 94 parts by weight of zirconia, and then pre-sinter at 620 ° C After 1.2 hours, 3 parts by weight of paraffin was added for ball milling, mixing and sieving to obtain a partially stabilized zirconia powder substrate.

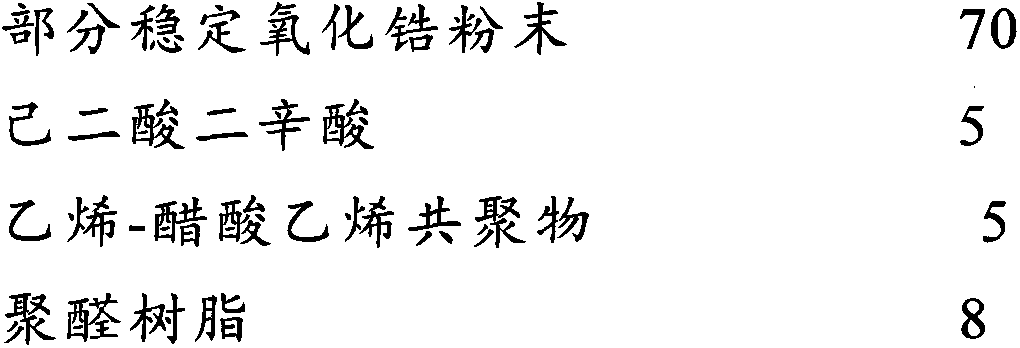

[0109] Step 2. Mix the partially stabilized zirconia powder substrate prepared above with organic carriers such as binders, surface active agents, and plasticizers in a certain proportion. The raw materials used in this step include in parts by weight:

[0110]

[0111]

[0112] Raise the temperature of the internal mixer to 120°C, then add the above-mentioned partially stabilized zirconia powder and polystyrene into the above-mentioned internal mixer, mix and stir for 10-20 minutes, so that the polystyrene is evenly included on the powder particles, and then Add the polyethylene glycol of cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com