Composite titanium dioxide and preparation method thereof

A composite titanium dioxide and titanium dioxide technology, which is applied in chemical instruments and methods, dyed organic silicon compound treatment, dyed high molecular organic compound treatment and other directions, can solve the problems such as the restriction of the dispersion state of composite titanium dioxide and the failure to be widely used. , to achieve the effects of good compatibility, improved whiteness, and reduced cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

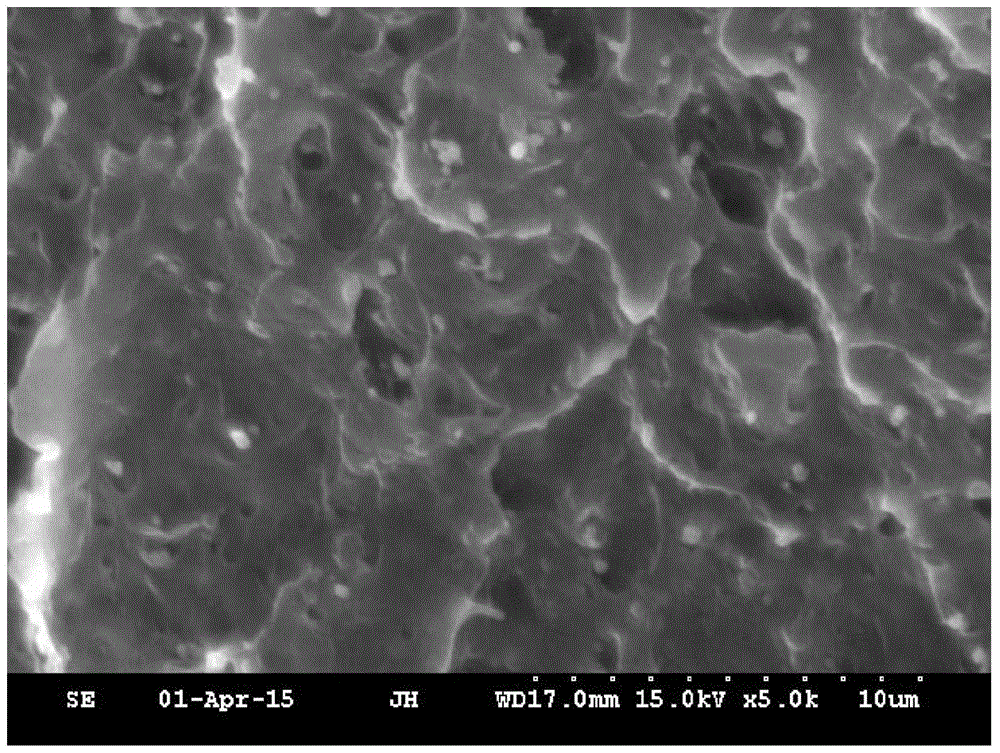

Image

Examples

Embodiment 1

[0012] Add the calcium oxide material to 85°C hot water for digestion reaction, stir until the calcium oxide is completely digested into calcium hydroxide, and then stand still for 24 hours without air. After filtering through a 200-mesh sieve to remove the residue, add water to dilute, adjust the concentration of calcium hydroxide to 0.2mol / L and transfer it to a reaction glass column. Pass the vent glass tube to the bottom of the glass column, and carbonize the mixture of carbon dioxide and nitrogen according to the molar ratio of 3:10 through the gas tube. The reaction was carried out at a reaction temperature of 0° C., and the change of the pH value was detected, and the aeration was stopped when the pH value reached 7. The average particle size of the obtained nanometer calcium carbonate is 45nm. The obtained nano-calcium carbonate slurry is poured into a reaction kettle to carry out surface graft polymerization. Add 2wt% MMA polymerization monomer of calcium carbonate ...

Embodiment 2

[0015] Add the calcium oxide material to 90°C hot water for digestion reaction, stir until the calcium oxide is completely digested into calcium hydroxide, and then stand still for 24 hours without air. After filtering through a 250-mesh sieve to remove the residue, add water to dilute, adjust the concentration of calcium hydroxide to 0.3mol / L and transfer it to a reaction glass column. Pass the vented glass tube to the bottom of the glass column, and carbonize the mixture of carbon dioxide and nitrogen according to the molar ratio of 4:10 through the gas tube. The reaction was carried out at a reaction temperature of 5° C., and the change of the pH value was detected, and aeration was stopped when the pH value reached 7. The average particle size of the obtained nano-calcium carbonate is 50nm. The obtained nano-calcium carbonate slurry is poured into a reaction kettle to carry out surface graft polymerization. Add 2wt% MMA polymerization monomer of calcium carbonate mass, a...

Embodiment 3

[0018] Add the calcium oxide material to 95°C hot water for digestion reaction, stir until the calcium oxide is completely digested into calcium hydroxide, and then stand still for 24 hours without air. After filtering through a 250-mesh sieve to remove the residue, add water to dilute, adjust the concentration of calcium hydroxide to 0.35mol / L and transfer it to a reaction glass column. Pass the vent glass tube to the bottom of the glass column, and carbonize the mixture of carbon dioxide and nitrogen according to the molar ratio of 4:12 through the gas tube. The reaction was carried out at a reaction temperature of 0° C., and the change of the pH value was detected, and the aeration was stopped when the pH value reached 7. The average particle size of the obtained nanometer calcium carbonate is 48nm. The obtained nano-calcium carbonate slurry is poured into a reaction kettle to carry out surface graft polymerization. Add 2wt% MMA polymerization monomer of calcium carbonate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com