High-voltage electrolyte for lithium ion battery

A lithium-ion battery and high-voltage technology, applied in the field of lithium-ion batteries, can solve the problems of toxicity, poor thermal stability, and low solubility of LiBOB, and achieve the effects of high conductivity, good compatibility, and high charging capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

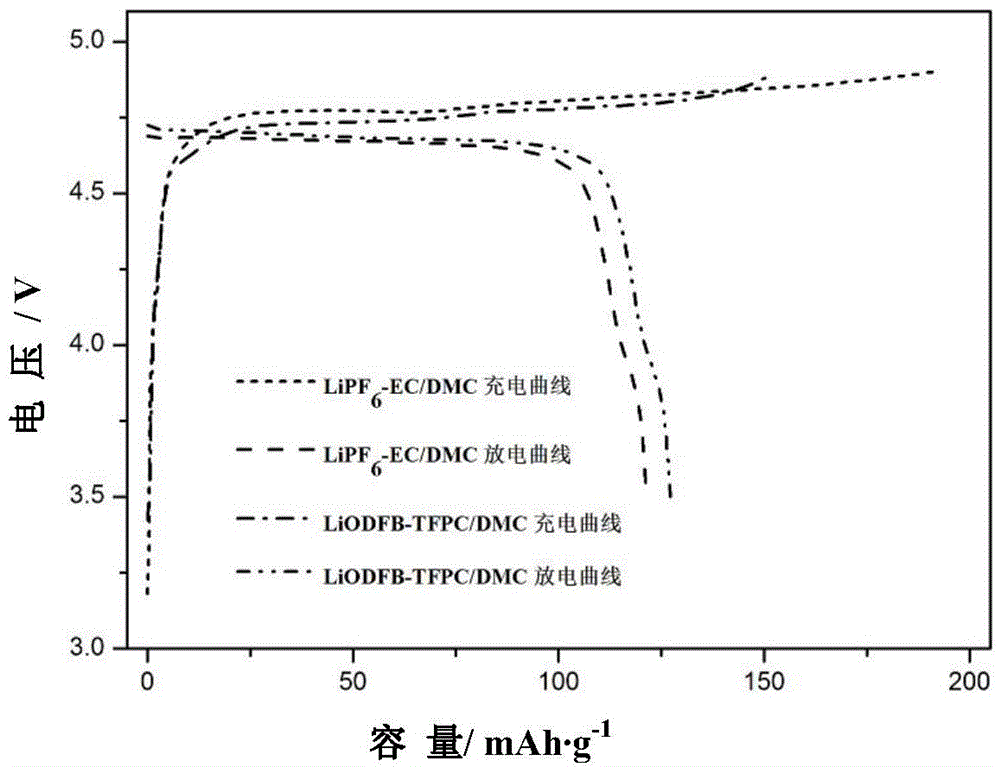

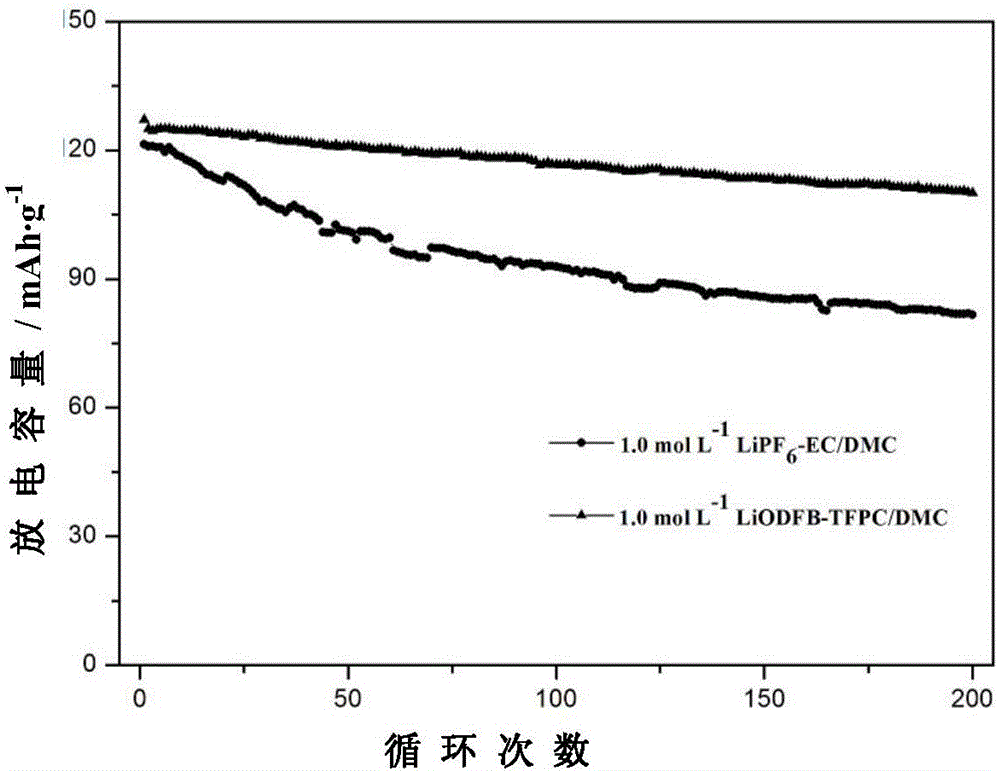

[0034] The battery-grade fluorinated solvent 4-trifluoromethylethylene carbonate (TFPC) and dimethyl carbonate (DMC) were prepared as a mixed solvent in a glove box filled with argon gas at a volume ratio of 1:1, and slowly added under stirring Lithium salt lithium difluorooxalate borate (LiODFB), configure 1.0mol / L LiODFB electrolyte. The conductivity of the electrolyte at -15°C, 25°C and 60°C was tested with a DDSJ-308A conductivity meter, and they were 1.5ms / cm, 5.62ms / cm and 9.72ms / cm, respectively.

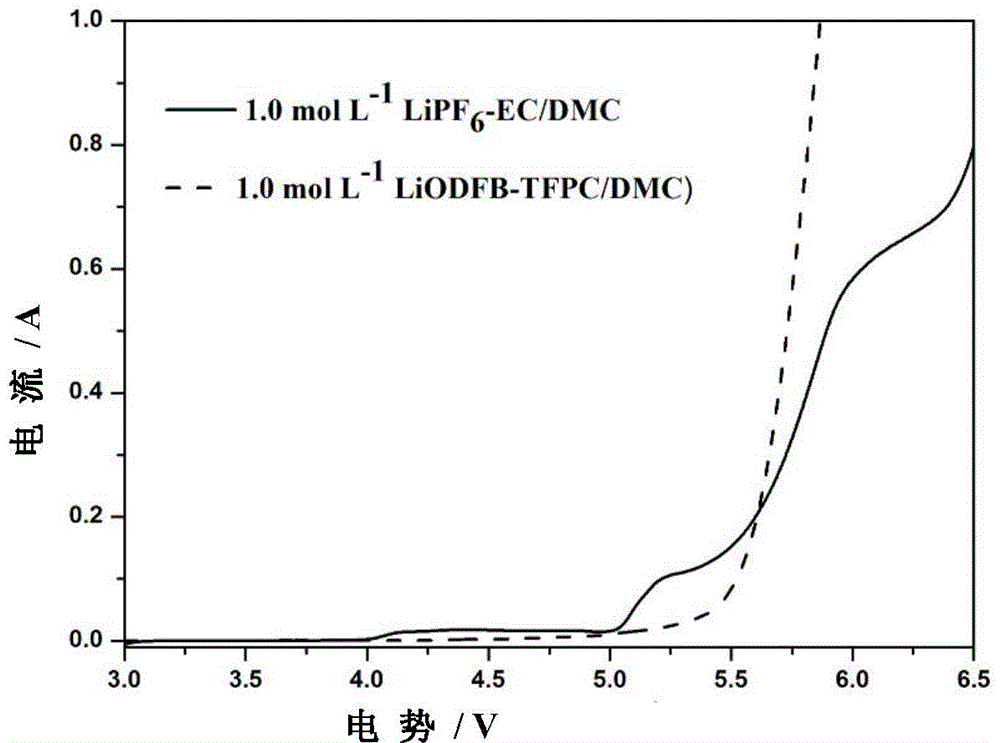

[0035]The fluorine-containing high-voltage electrolyte 1.0mol / L LiODFB-TFPC / DMC (volume ratio 1:1) and the conventional electrolyte 1.0mol / L LiPF 6 -EC / DMC (volume ratio 1:1) uses Pt as the working electrode, metal lithium as the counter electrode and reference electrode to test the oxidation potential of the electrolyte, the test voltage range is 3.0-6.5V, and the scan speed is 5mV / s. The oxidation potential of the electrolyte configured in this embodiment is as high as 5...

Embodiment 2

[0037] The battery-grade fluorinated solvent fluorinated ethylene carbonate (FEC) and dimethyl carbonate (DMC) were prepared as a mixed solvent in a glove box filled with argon at a volume ratio of 1:1, and lithium salt difluoride was slowly added under stirring. Lithium oxalate borate (LiODFB), configure 1.0mol / L LiODFB electrolyte.

[0038] The fluorine-containing high-voltage electrolyte configured in this embodiment and the conventional electrolyte 1.0mol / L LiPF 6 -EC / DMC (volume ratio 1:1) uses Pt as the working electrode, metal lithium as the counter electrode and reference electrode to test the oxidation potential of the electrolyte, the test voltage range is 3.0-6.5V, and the scan speed is 5mV / s. The oxidation potential of the electrolyte configured in this embodiment is as high as 5.2V.

Embodiment 3

[0040] The battery-grade fluorinated solvent 4-trifluoromethylethylene carbonate (TFPC), fluoroethylene carbonate (FEC), ethylene carbonate (EC) and dimethyl carbonate (DMC) were mixed in a volume ratio of 1:1:1 : 1 configure a mixed solvent in a glove box full of argon, slowly add lithium salt lithium difluorooxalate borate (LiODFB) under stirring, and configure a 1.0mol / L LiODFB electrolyte.

[0041] The fluorine-containing high-voltage electrolyte configured in this embodiment and the conventional electrolyte 1.0mol / L LiPF 6 -EC / DMC (volume ratio 1:1) uses Pt as the working electrode, metal lithium as the counter electrode and reference electrode to test the oxidation potential of the electrolyte, the test voltage range is 3.0-6.5V, and the scan speed is 5mV / s. The oxidation potential of the electrolyte configured in this embodiment is as high as 5.5V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com