Device and method for removing fine particles by sound wave combined with electric field

A fine particle removal technology, applied in the direction of electrostatic separation, external electrostatic separator, etc., can solve the problem of low removal efficiency of fine particles, achieve the effect of improving agglomeration removal efficiency, reducing space, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

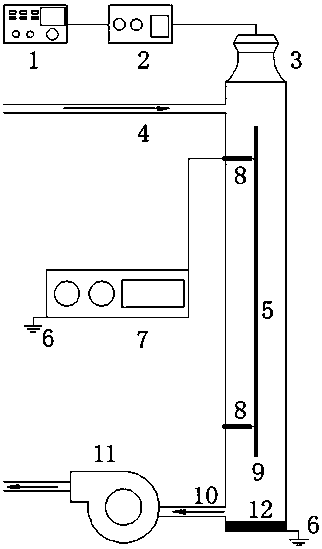

[0015] like figure 1 As shown, a device for removing fine particles by the action of sound wave combined with electric field includes signal generator 1, power amplifier 2, compression drive sound source 3, flue gas inlet 4, agglomeration removal chamber main body 5, grounding device 6, negative direct current Power supply 7, discharge electrode fixing device 8, discharge electrode 9, flue gas outlet 10, induced draft fan 11, sound-absorbing sponge 12; a discharge electrode 9 is arranged at the center of the main body 5 of the agglomeration removal chamber, and the discharge electrode 9 is fixed by the discharge electrode The device 8 is fixed, the negative DC power supply 7 is connected to the discharge electrode 9 through the discharge electrode fixing device 8 through the wire, the top of the main body 5 of the agglomeration removal chamber is provided with a compression driving sound source 3, and the compression driving sound source 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com