Solid oxide fuel cell cathode material and its composite cathode material and its preparation method and battery composite cathode preparation method

A fuel cell cathode, solid oxide technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as performance degradation, difficulty in sintering and bonding of double perovskite cathode materials and electrolyte layers, etc., to increase electrical conductivity, improve The effect of battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Solid phase synthesis method:

[0045] to La 2 o 3 , SrCO 3 ,Co 2 o 3 , Fe 2 o 3 As raw material, according to La 1.2 Sr 0.8 co 0.8 Fe 0.2 o 4+δ The stoichiometric ratio of the mixture was prepared, and alcohol was used as a medium, and ball milled in an agate ball mill jar for 24 hours. After mixing evenly, it was dried in an oven at 120°C. Put the dried powder in the air at 1200°C for 12 hours, after cooling, use alcohol ball mill for 24 hours, dry at 120°C, and pass through a 200-mesh sieve to obtain La 1.2 Sr 0.8 co 0.8 Fe 0.2 o 4+δ Powder.

[0046] Synthetic La 1.2 Sr 0.8 co 0.8 Fe 0.2 o 4+δ Powder and Ce 0.8 SM 0.2 o 2 Mix according to the mass ratio of 70:30, ball mill for 24 hours to mix evenly, and dry at 120°C to obtain La 1.2 Sr 0.8 co 0.8 Fe 0.2 o 4+δ +Ce 0.8 SM 0.2 o 2 Composite cathode materials for solid oxide fuel cells.

Embodiment 2

[0048] Polymer precursor method:

[0049] Hydrated La(NO 3 ) 3 , hydrated Pr(NO 3 ) 3 , hydrated Ni(NO 3 ) 2 , hydrated Cu(NO 3 ) 2 As raw material, according to La 1.425 PR 0.475 Ni 0.8 Cu 0.2 o 4+δ The stoichiometric ratio is dissolved in deionized water to prepare solution a, and at the same time, an appropriate amount of citric acid and ethylene glycol are added to deionized water and stirred until completely dissolved to form solution b, wherein the molar ratio of metal ions: citric acid: ethylene glycol is 1:2:4. Mix solution b and solution a, stir until uniform, then continue heating and stirring at 80°C to form a gel, then place the gel at 400°C for 2 hours to carbonize the resin, and place the obtained porous foam product in the air for calcination at 1200°C After cooling for 12 hours, use alcohol ball milling for 24 hours, dry at 120°C, and pass through a 200-mesh sieve to obtain La 1.425 PR 0.475 Ni 0.8 Cu 0.2 o 4+δ Powder.

[0050] Synthetic La ...

Embodiment 3

[0052] Glycine-nitrate method:

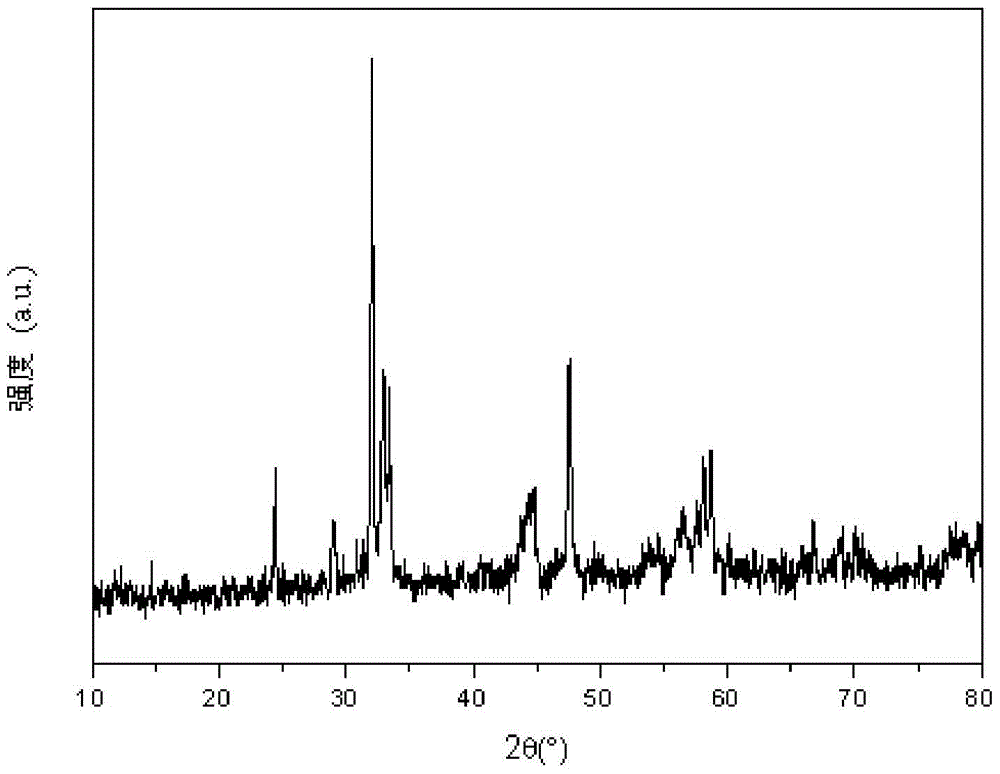

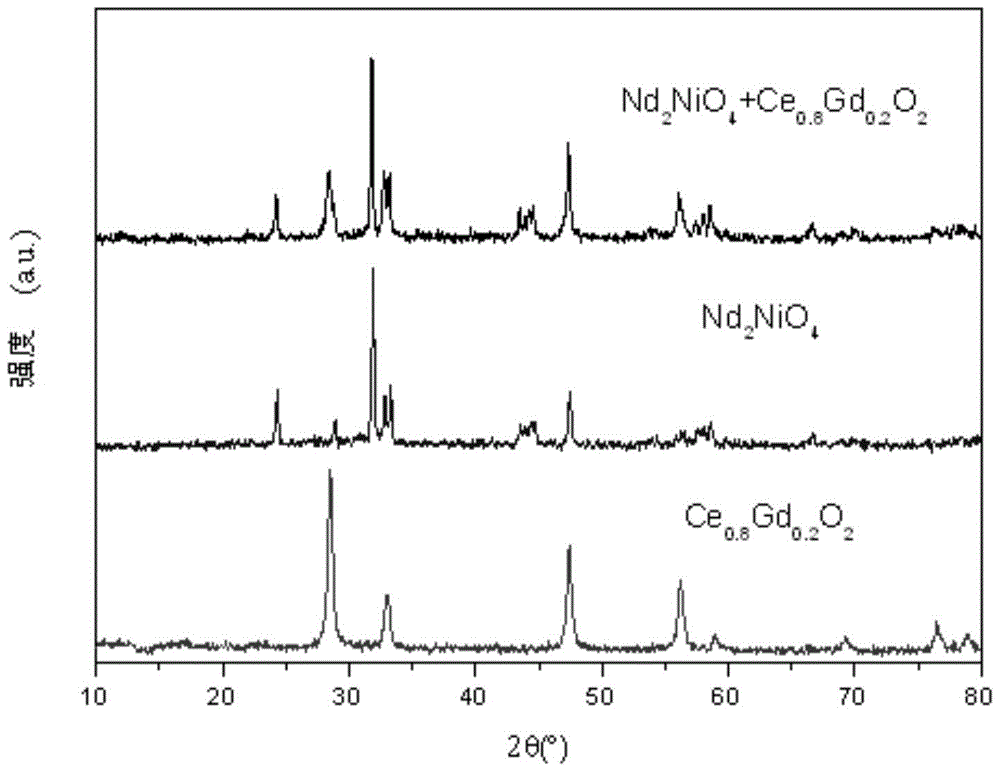

[0053] With hydrated Nd(NO 3 ) 3 , hydrated Ni(NO 3 ) 2 , hydrated Co(NO 3 ) 2 As raw material, according to Nd 1.95 Ni 0.7 co 0.3 o 4+δ Dissolve the stoichiometric ratio in deionized water, then add an appropriate amount of glycine and stir evenly to form a solution, wherein the molar ratio of glycine: metal ion is 2:1, heat and stir at 100°C to form a wet gel, then increase the temperature to 250°C, After burning, collect the precursor powder and place it under argon for calcination at 1200°C for 12 hours, then place it under air again at 800°C for 12 hours, and after cooling, use alcohol ball mill for 24 hours, dry at 120°C, and pass through a 200-mesh sieve to obtain Nd 1.95 Ni 0.7 co 0.3 o 4+δ Powder.

[0054] with synthetic Nd 1.95 Ni 0.7 co 0.3 o 4+δ Powder and Ce 0.8 Gd 0.2 o 2 Mix according to the mass ratio of 50:50, ball mill for 24 hours to mix evenly, and dry at 120°C to get Nd 1.95 Ni 0.7 co 0.3 o 4+δ +Ce ...

PUM

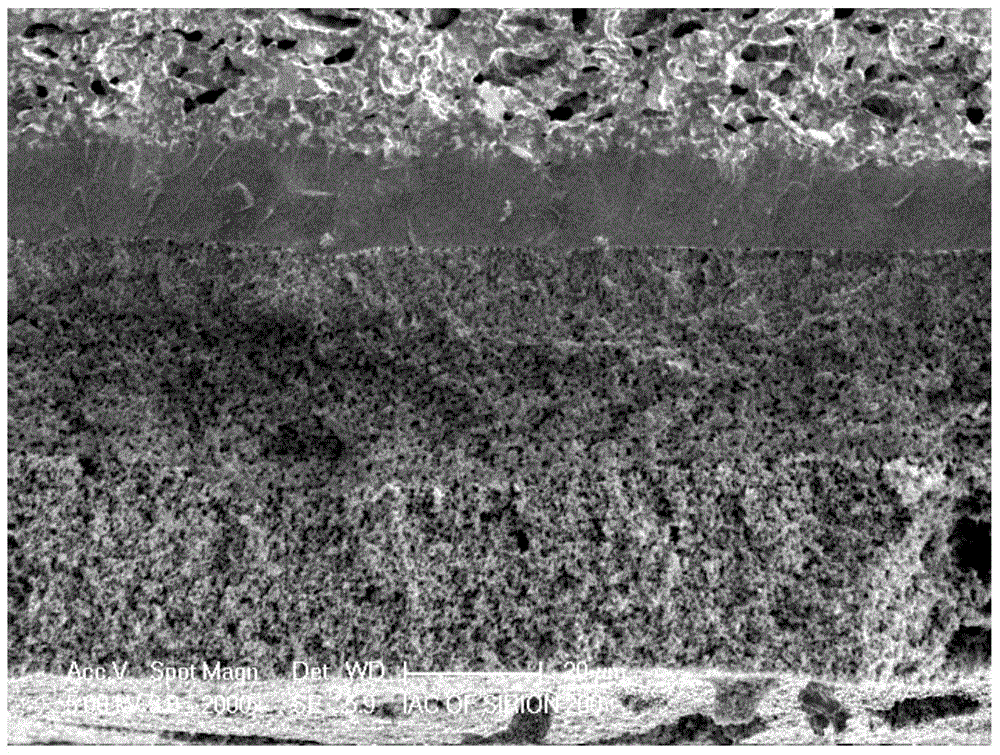

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com