Surface modification method for implant tooth nail by plasma immersion ion implantation technology

A technology of immersion ion implantation and plasma, which is applied in ion implantation plating, metal material coating process, vacuum evaporation plating, etc., can solve the problem of unsatisfactory biological activity, osteogenic activity and antibacterial performance on the surface of implanted dental nails. Poor combination of human tissue and weak osseointegration ability of implant materials, etc., to achieve the effect of improving biological activity and antibacterial performance, improving corrosion resistance and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The dental implant nails treated with sandblasting acid were ultrasonically cleaned and then dried naturally for use. Plasma immersion ion implantation (PIII) technology was used to inject zinc and silver binary ions into the implant nails, the sequence was zinc first and then silver (Zn-Ag-PIII). The specific process parameters are shown in Table 1:

[0041] target pulse arc Injection voltage (kV) -30 Injection pulse width (μs) 450 450 Frequency (Hz) 7 7 Injection time (h) Zinc 1.5 / Silver 1.5 Vacuum (Pa) 3.5×10 -3

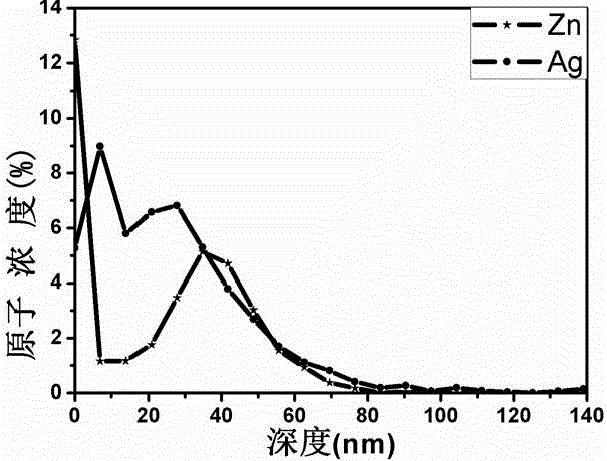

[0042] figure 1 It is the depth distribution diagram of zinc and silver on the surface of the dental implant obtained through modification treatment in this embodiment. Depend on figure 1 It can be seen that after the modification treatment of this embodiment, the two elements of zinc and silver are distributed on the surface of the dental implant.

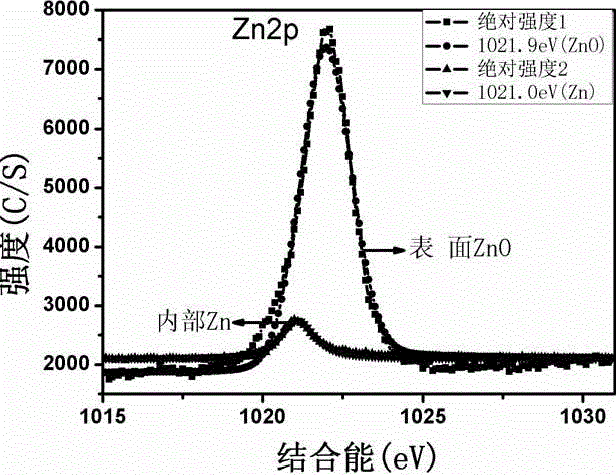

[0043]Fig. 2(a) is the high-resolution sp...

Embodiment 2

[0046] The dental implant nails treated with sandblasting acid were ultrasonically cleaned and then dried naturally for use. Plasma immersion ion implantation (PIII) technology was used to implant zinc and silver binary ions into the implant nails, the sequence was first silver and then zinc (Ag-Zn-PIII). The specific process parameters are shown in Table 2:

[0047] target pulse arc Injection voltage (kV) -15 Injection pulse width (μs) 250 250 Frequency (Hz) 5 5

[0048] Injection time (h) Silver 1.5 / Zinc 1.5 Vacuum (Pa) 3.5×10 -3

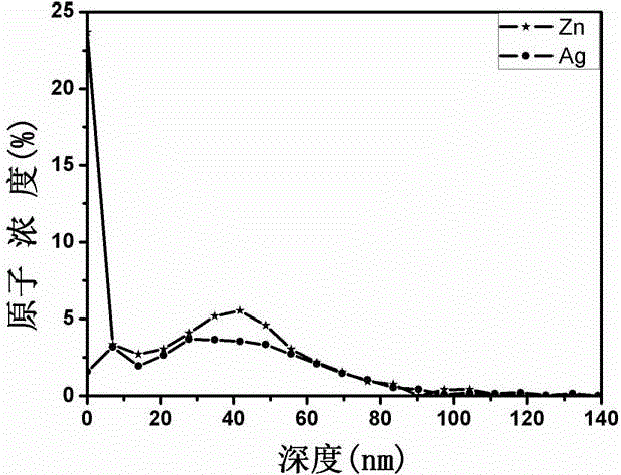

[0049] image 3 It is the depth distribution diagram of zinc and silver on the surface of the dental implant obtained through modification treatment in this embodiment. as illustrated:

[0050] After the modification treatment in this embodiment, the two elements of zinc and silver are distributed on the surface of the dental implant.

[0051] Fig. 4(a) is a high-resolutio...

Embodiment 3

[0054] The dental implant nails treated with sandblasting acid were ultrasonically cleaned and then dried naturally for use. Plasma immersion ion implantation (PIII) technology was used to implant zinc and silver binary ions into the dental implant, and the order was zinc-silver co-implantation (Zn / Ag-PIII). The specific process parameters are shown in Table 3:

[0055] target pulse arc Injection voltage (kV) -30 Injection pulse width (μs) 450 450 Frequency (Hz) 9 9 Injection time (h) Zinc 1.5 / Silver 1.5 Vacuum (Pa) 3.5×10 -3

[0056] Figure 5 It is the depth distribution diagram of zinc and silver on the surface of the dental implant obtained through modification treatment in this embodiment. as illustrated:

[0057] After the modification treatment in this embodiment, the two elements of zinc and silver are distributed on the surface of the dental implant.

[0058] Fig. 6(a) is a high-resolution spectrum of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com