An analytical method for rapid combined measurement of ni, cu, fe, s, pb, zn, as, sb, bi, sio2 in matte

A matte and joint measurement technology, which is applied in the fields of analyzing materials, using wave/particle radiation for material analysis, measuring devices, etc. and other problems, to achieve the effect of fast detection and analysis, solving inaccurate detection, and saving processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

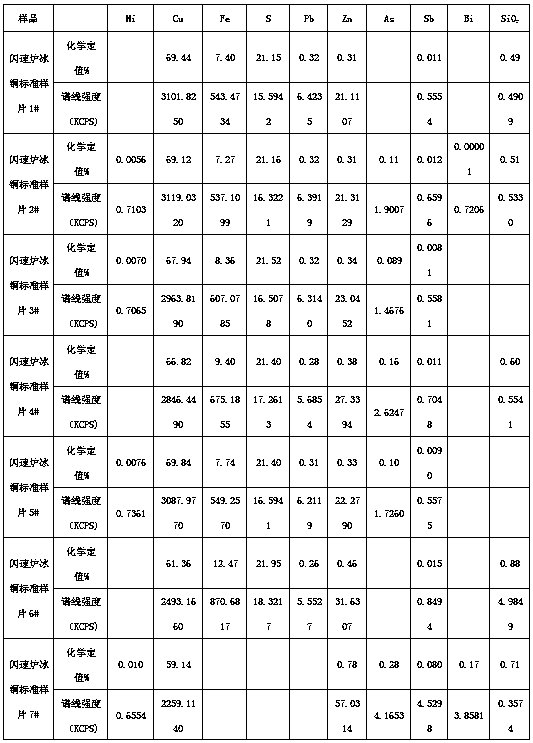

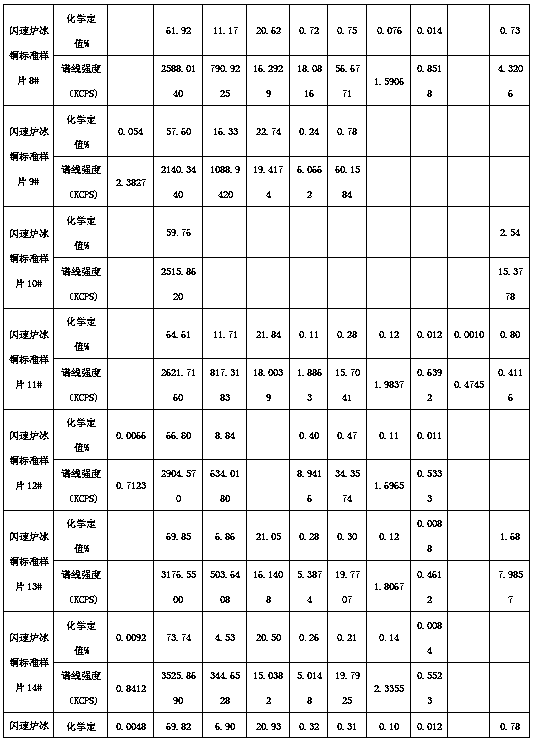

[0029] The present invention will be further described below in conjunction with specific examples.

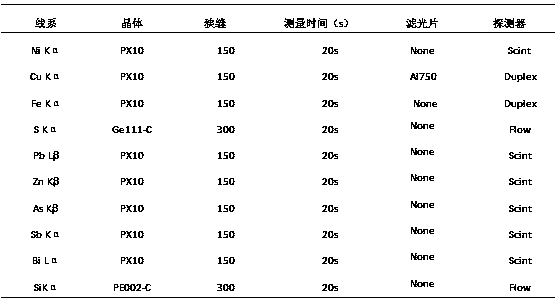

[0030] A rapid joint measurement of Ni, Cu, Fe, S, Pb, Zn, As, Sb, Bi, SiO in matte 2 The analysis method, this method comprises the following steps:

[0031] Step 1. Grinding the sample to be tested: Take 100-150g of the matte sample to be tested and put it into a grinding table, grind it in the sample pulverizer for 50-60s, control the particle size to be greater than 120 mesh, and pack it into a bag.

[0032] Step 2. Pressing the sample piece to be tested: Put a circular funnel-shaped sample mold with a diameter of 32mm into the press machine, take 4-6g of the matte sample to be tested with a horn spoon and put it into the mold, and use industrial boric acid 10- 20g edging bottom, under the conditions of pressure 20-25T and holding time 25-30s, make a sample piece with a diameter of 32mm on a hydraulic sample making machine with a range of 0-50T, and blow off the adhered b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com