Method for rapidly and continuously measuring multiple elements in ferronickel

A determination method and multi-element technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that cannot meet the control time limit requirements of pyrometallurgy process, there are many kinds of chemical reagents, and the analysis time is long, so as to ensure the uniformity of samples , high practical value, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] 1. Determination steps

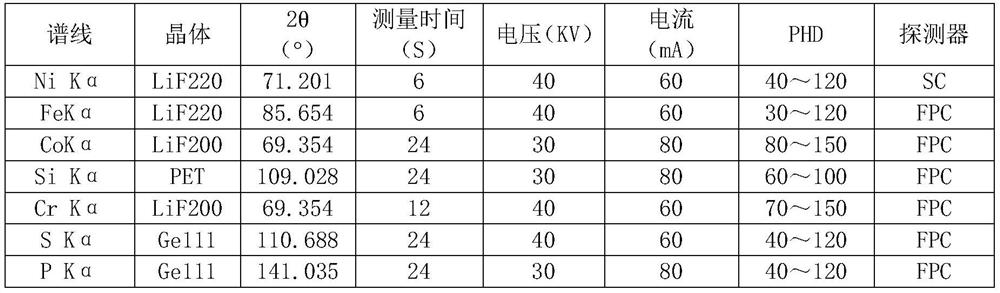

[0030] The present invention provides a complete method for realizing XRF multi-element rapid joint measurement of Ni, Fe, Si, Co, Cr, S, P in ferronickel, which specifically includes the following steps:

[0031] (11) Sampling of samples to be tested

[0032] In the nickel-iron melt discharge chute of the nickel-iron electric furnace, use a high-temperature ceramic fiber sampling spoon to take out the nickel-iron melt (about 280g) from the flowing nickel-iron melt, pour it into a sampling mold (made of cast iron), Cool quickly by dipping in water, and pour out the nickel-iron-like ingot.

[0033] Among them, the ferronickel melt collected during sampling must be quickly poured into the mold and cooled by dipping in water quickly to prevent segregation that may be caused by slow cooling.

[0034] The geometric dimensions of the sample ingot are: a cylindrical body with a length of 600mm*upper φ35mm*lower φ33mm; put the sample ingot into a samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com