System and preparation method of a high-temperature wear-resistant composite material

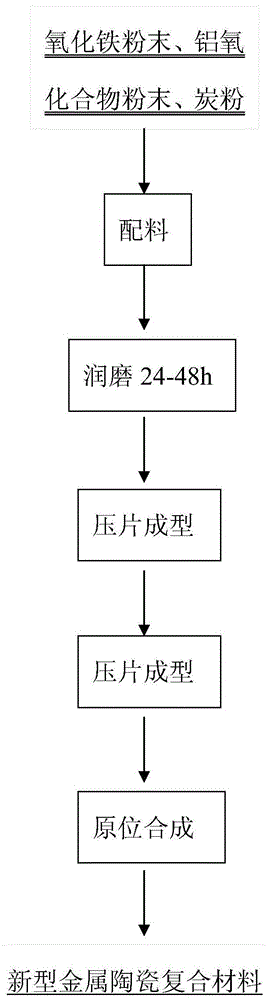

A composite material, high temperature wear resistance technology, applied in the field of new system metal ceramic composite material and its preparation, can solve the problem that the reaction speed of aluminum powder reduction iron oxide is difficult to control, the shape of high temperature wear resistance lining is difficult to control, and the physical compatibility is affected. and chemical compatibility and other issues, to achieve the effect of eliminating the need for reinforcement pretreatment process, good compatibility, and uniform distribution of physical and metal phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take Fe with particle size less than 20 microns 3 o 4 Powder, Al 2 o 3 Powder and activated carbon powder, according to M Fe / M Al =0.9, M O / M C = 1.5 ratio ingredients. Add an appropriate amount of dispersant to the prepared powder and mix it in a ball mill for 24 hours. The ratio of balls to materials is 3:1. The speed of the ball mill is 100 rpm. The materials are mixed evenly. After curing, the molding pressure is 5MPa, the pressure holding time is 5 minutes, pressed into a φ25.5±0.5mm cylinder, and dried under low temperature vacuum. The pressed cylindrical sheet is sintered at 1300°C in an atmosphere of nitrogen and argon with a volume ratio of 1:1, the auxiliary pressure is 10MPa, the holding time is 5 minutes, and cooled to room temperature to obtain Fe-FeAl 2 o 4 Cermet. The obtained product is detected, and the mass percentages of the metal phase and the non-metal phase are 33% and 67% respectively.

[0035] The wetting angle of the phase is small,...

Embodiment 2

[0037] Take Fe with particle size less than 20 microns 2 o 3 、Al 2 o 3 Powder and coke powder, according to M Fe / M Al =1.2, M O / M C = 1.0 scale ingredients. Add an appropriate amount of dispersant to the prepared powder and mix it in a ball mill for 48 hours. The ratio of balls to materials is 10:1. The speed of the ball mill is 250 rpm. After curing, the forming pressure is 30MPa, the holding time is 1 minute, pressed into a φ25.5±0.5mm cylinder, and dried under vacuum at low temperature. Sintering at 1400°C under an argon atmosphere, the auxiliary pressure is 40MPa, and the sintering time is 25 minutes. Other preparation methods are the same as in Example 1 to obtain Fe-FeAl 2 o 4 Cermet. The obtained product is detected, and the mass percentages of the metal phase and the non-metal phase are 45% and 55% respectively.

[0038] The wetting angle of the phase is small, the interface is well bonded, the surface of the ceramic particles is pure, the compatibility be...

Embodiment 3

[0040] Take Fe with particle size less than 20 microns 3 o 4 , Fe 2 o 3 , Al(OH) 3 Powder and activated charcoal powder according to M Fe / M Al =1.1, M O / M C =1.2 Ratio ingredients, where Fe 3 o 4 / Fe 2 o 3 The molar ratio is 2:1. Add an appropriate amount of dispersant to the prepared powder and mix it in a ball mill for 36 hours. The ball-to-material ratio is 8:1, the ball mill speed is 200 rpm, and the material is mixed evenly. Take it out and dry it under low temperature vacuum, and add an appropriate amount of binder Finally, the forming pressure is 20MPa, the holding time is 3 minutes, pressed into a φ25.5±0.5mm cylinder, and dried under low temperature vacuum. Sintering at 1500°C under a nitrogen atmosphere, the auxiliary pressure is 20MPa, and the sintering time is 25 minutes. Other preparation methods are the same as in Example 1 to obtain Fe-FeAl 2 o 4 Cermet. The obtained product is detected, and the mass percentages of the metal phase and the non-me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com