Green quick method for preparing nano-silver sol using bagasse extract

A nano-silver sol and extractant technology, applied in the nano-field, can solve the problems of low utilization rate, environmental pollution, waste of resources, etc., achieve good stability and dispersion, solve the effect of easy agglomeration, and increase the value of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] First, under stirring conditions, NaOH solution with a mass concentration of 60 mg / mL was added dropwise to 80 mg / mL AgNO 3 solution until no more precipitation occurred; then 150 mg / mL ammonia water was added dropwise to the AgNO 3 mixed with NaOH until the precipitate is completely dissolved to form a more active [Ag(NH 3 ) 2 ] + state. Soak 0.2 g of bagasse powder in 5% NaOH aqueous solution with a solid-to-liquid ratio of 1:20 (g / mL), extract for 4 h to obtain the extract, and then according to the ratio of bagasse to silver nitrate (2 :3, g / g), add the newly prepared silver ammonia solution, put it in a microwave reactor, adjust the microwave power to 700 W, and the microwave temperature to 60 ℃, and the stable nano-silver sol can be obtained after microwave reaction for 70 min. After the nano-silver sol was centrifuged in a high-speed centrifuge (14000 r / min, 35 min) to precipitate, and then re-dissolved in water, it was still uniformly dispersed and not easy ...

Embodiment 2

[0031] First, under stirring conditions, NaOH solution with a mass concentration of 100 mg / mL was added dropwise to 60 mg / mL AgNO 3 solution until no more precipitation occurred; then 300 mg / mL ammonia water was added dropwise to the AgNO 3 mixed with NaOH until the precipitate is completely dissolved to form a more active [Ag(NH 3 ) 2 ] + state. Soak 0.2 g of bagasse powder in NaOH aqueous solution with a mass fraction of 4%, with a solid-to-liquid ratio of 1:23 (g / mL), extract for 5 h to obtain the extract, and then according to the ratio of bagasse to silver nitrate (1 :1, g / g), add the newly prepared silver ammonia solution, place it in a microwave reactor, adjust the microwave power to 900 W, and the microwave temperature to 80 °C, and the stable nano-silver sol can be obtained after microwave reaction for 30 min. After the nano-silver sol was centrifuged in a high-speed centrifuge (13000 r / min, 40 min) to precipitate, and then re-dissolved in water, it was still unif...

Embodiment 3

[0033] First, under stirring conditions, NaOH solution with a mass concentration of 150 mg / mL was added dropwise to 120 mg / mL AgNO 3 solution until no more precipitation occurred; then 800 mg / mL ammonia water was added dropwise to the AgNO 3 mixed with NaOH until the precipitate is completely dissolved to form a more active [Ag(NH 3 ) 2 ] +state. Soak 0.2 g of bagasse powder in NaOH aqueous solution with a mass fraction of 3%, with a solid-to-liquid ratio of 1:25 (g / mL), extract for 3 h to obtain the extract, and then according to the ratio of bagasse to silver nitrate (2 : 1, g / g), add the newly prepared silver ammonia solution, put it in the microwave reactor, adjust the microwave power to 800 W, and the microwave temperature to 70 ℃, and the stable nano-silver sol can be obtained after microwave reaction for 50 min. After the nano-silver sol was centrifuged in a high-speed centrifuge (15000 r / min, 30 min) to precipitate, and then re-dissolved in water, it was still unif...

PUM

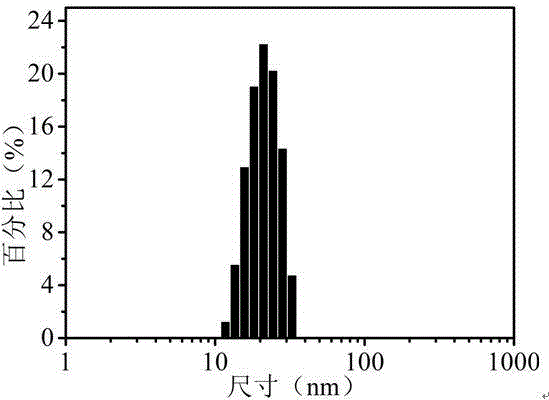

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com