Adhesive-free FCCL (flexible copper-clad laminate) with two medium layers

A technology for adhesive-flexible and copper-clad laminates, applied in the field of double-layer dielectric non-adhesive flexible copper-clad laminates, can solve the problems of reducing the thickness of non-adhesive flexible copper-clad laminates, low product dimensional stability, and difficult processing, saving raw materials, The effect of good appearance and performance, high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

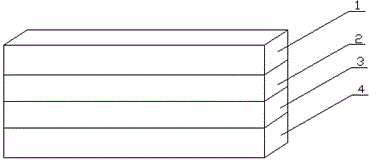

[0045] A double-layer dielectric adhesive-free flexible copper-clad laminate is composed of a first copper foil 1, a second copper foil 4, and an insulating layer between the first copper foil 1 and the second copper foil 4 arranged in parallel. The layers include thermoplastic polyimide layer 2 and polyimide structural film layer 3 .

[0046] In this embodiment, the thicknesses of the first copper foil 1 and the second copper foil 4 are respectively 7 μm; the thickness of the thermoplastic polyimide layer 2 is 1 μm; the thickness of the polyimide structure film layer 3 is 5 μm;

[0047] The total thickness of the copper clad laminate in this embodiment is 20 μm, which is suitable for electronic products with high thickness requirements, such as mobile phones and other fields.

Embodiment 2

[0049] A double-layer dielectric adhesive-free flexible copper-clad laminate is composed of a first copper foil 1, a second copper foil 4, and an insulating layer between the first copper foil 1 and the second copper foil 4 arranged in parallel. The layers include thermoplastic polyimide layer 2 and polyimide structural film layer 3 .

[0050] In this embodiment, the thicknesses of the first copper foil 1 and the second copper foil 4 are respectively 12 μm; the thickness of the thermoplastic polyimide layer 2 is 3 μm; the thickness of the polyimide structure film layer 3 is 10 μm; in this embodiment The total thickness of the copper clad laminate is 37 μm.

Embodiment 3

[0052] A double-layer dielectric adhesive-free flexible copper-clad laminate is composed of a first copper foil 1, a second copper foil 4, and an insulating layer between the first copper foil 1 and the second copper foil 4 arranged in parallel. The layers include thermoplastic polyimide layer 2 and polyimide structural film layer 3 .

[0053] In this embodiment, the thickness of the first copper foil 1 and the second copper foil 4 is 35 μm; the thickness of the thermoplastic polyimide layer 2 is 7 μm; the thickness of the polyimide structure film layer 3 is 15 μm; the copper clad laminate of this embodiment The total thickness is 92 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com