Reinforcing structure of existing structural beams and construction method thereof

A technology for strengthening structures and existing structures, applied in building construction, building maintenance, construction, etc., can solve problems such as inability to meet local concentrated loads, limited bending and shearing resistance, and high economic costs, and achieve Avoiding economic losses, improving bending and shearing resistance, and convenient and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

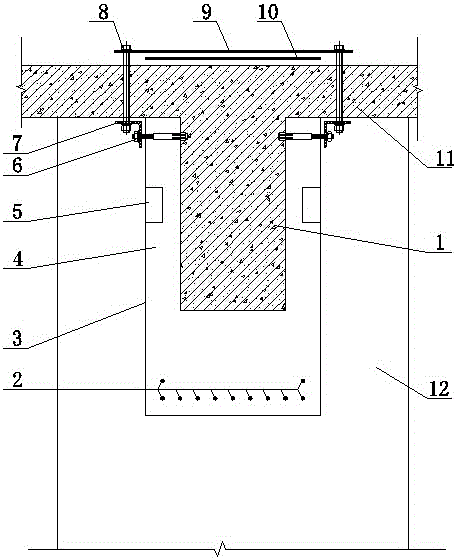

[0024] Such as figure 1 Shown, a kind of reinforcement structure of existing structural beam, comprises structural beam 1, and the two ends of structural beam 1 are connected with structural column 12, and structural beam 1 is provided with outsourcing steel sheath 3, and the top of outsourcing steel sheath 3 is connected with The lower surface of the beam plate 11 where the structural beam 1 is located is bonded, and the end is bonded to the structural column 12. At least 5 reinforcing ribs 2 are arranged between the bottom of the structural beam 1 and the outer steel sleeve 3, and the ends of the reinforcing ribs 2 part of the structure column 12, and grouting holes 5 are provided on both sides of the outsourcing steel jacket 3, through which the CGM slurry 4 is poured into the outsourcing steel jacket 3. 11 The junction is symmetrically provided with a plurality of angle steels 7, the vertical part of the angle steel 7 is connected with the structural beam 1 through the anc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com